I made a tiny design change on a trivial device, but I think it’s a simple example of DFM (Design For Manufacturing) & associated scale issues.

The devices is this orange clip that I included with all my cables so people don’t lose track of them, as commonly happens (bad!)

1/n

The devices is this orange clip that I included with all my cables so people don’t lose track of them, as commonly happens (bad!)

1/n

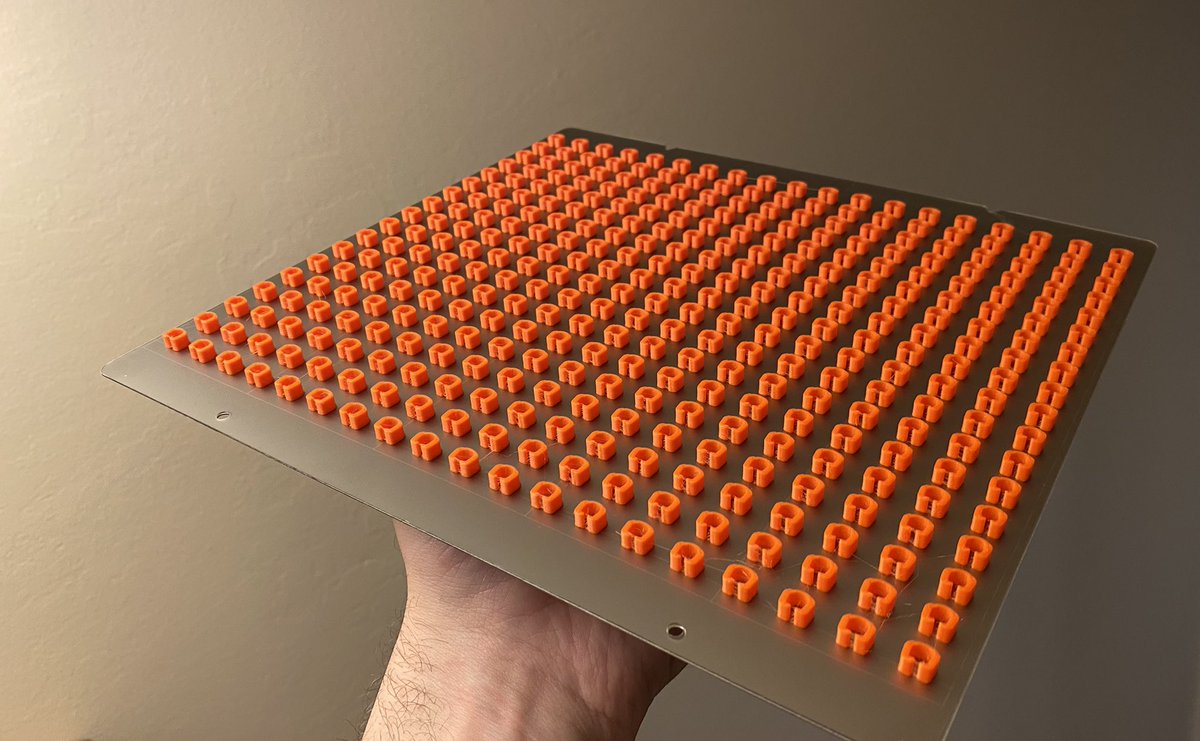

I personally test, pack, & sometimes finish assembly for 100% of the OMG Cables. That means I can do silly things like decide to 3D print some orange clips to toss in.

So I print 300 on a single plate. Takes 3.5hrs. Then I toss them in a bag & take some out as needed

2/n

So I print 300 on a single plate. Takes 3.5hrs. Then I toss them in a bag & take some out as needed

2/n

I made them loose so they don’t mark the cables, but they have a serious problem when I’m bulk. They tangle together & it’s slow to untangle. Every. Single. Time.

3/n

3/n

An otherwise functional design suddenly doesn’t scale past a handful of them at once… like SO MANY manufacturing problems.

The fix is easy. Just bulk up a few areas. It changes print time from 3.5hrs to 5.5hrs, but it’s worth it.

4/n

The fix is easy. Just bulk up a few areas. It changes print time from 3.5hrs to 5.5hrs, but it’s worth it.

4/n

Read on Twitter

Read on Twitter