Want cliff notes on the chip shortage?

It’s fairly complex with all kinds of defensive & offensive tactics at play, but here is a summary from my position:

1/n

It’s fairly complex with all kinds of defensive & offensive tactics at play, but here is a summary from my position:

1/n

I design PCBs & have them assembled. All the little components on the board are purchased from a supplier, and have a reliable cost.

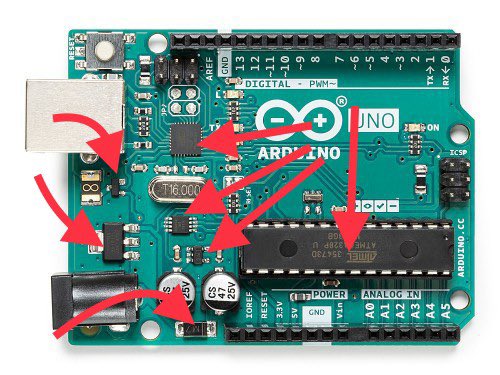

Many of the components have a piece of silicon inside them. Take this Arduino PCB for instance:

2/n

Many of the components have a piece of silicon inside them. Take this Arduino PCB for instance:

2/n

There are very few places that can produce this piece of silicon. The component makers are basically paying for time slots on the machines at the silicon fabs.

The pandemic cause auto makers to cancel their slots because they expected low demand.

3/n

The pandemic cause auto makers to cancel their slots because they expected low demand.

3/n

All the other component makers gladly took the slots. But then the auto makers realized their estimates were wrong. So they bought back those slots at 6-8x the cost. And governments pushed to give priority to the auto makers.

4/n

4/n

This translates to higher costs for everyone else, but also much longer wait times as everyone gets bumped out. Add in increased chip demand, & suddenly we have shortages.

If just one component is out of stock, my entire PCB cannot be made.

5/n

If just one component is out of stock, my entire PCB cannot be made.

5/n

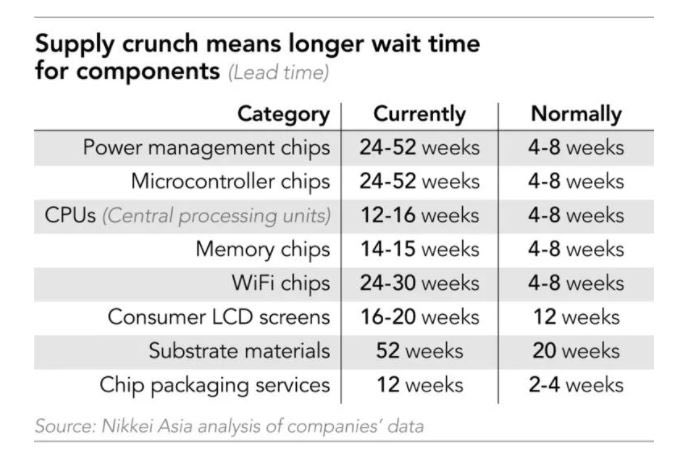

Normally that means waiting 1-2months for the stock to come back. But now the lead time is more like 1 year.

6/n

6/n

The amount of finished components on the market is fairly limited. So now PCB manufacturers of all sizes are resorting to buying up what they can and hoarding it. If they don’t, they won’t have products for their customers for a year or longer.

7/n

7/n

But you also have market competitors. What happens if your competitor has components but you don’t? What happens if you buy up what your competitor needs to hurt them? (it’s happening!)

8/n

8/n

When it gets down to the small independent hardware makers, we don’t have as much $ to participate in most of this.

If we are lucky, we can rebuild our PCB to use a different component. But by the time you do so, the replacement part is out of stock.

9/n

If we are lucky, we can rebuild our PCB to use a different component. But by the time you do so, the replacement part is out of stock.

9/n

There is way more going on, but that’s the high level.

You will probably see hardware go out of stock for extended periods of time. And if the maker is small, they may not survive long enough to put them back on the shelves. Sadly, that has already started happening.

10/n

You will probably see hardware go out of stock for extended periods of time. And if the maker is small, they may not survive long enough to put them back on the shelves. Sadly, that has already started happening.

10/n

I’m certainly missing a lot here. So I welcome additional info!

People off the top of my head who are also in this space: @colinoflynn @securelyfitz @esden @ktemkin @Chris_Gammell @zhovner @obra @GregDavill @timonsku @joegrand @nwsayer

People off the top of my head who are also in this space: @colinoflynn @securelyfitz @esden @ktemkin @Chris_Gammell @zhovner @obra @GregDavill @timonsku @joegrand @nwsayer

I may actually do a video that allows this to be covered in slightly more depth if anyone is interested in viewing that (or collaborating on it!)

I have seen varying opinions on when chip supply returns to normal if nothing else bad happens (like one chip fab starting on fire, one losing power for an extended period, or the upcoming drought for another). Seems to be in the range of 1-2 years.

13/n

13/n

From that point, it usually takes 2-5 months for a PCB to get assembled and eventually go up for sale.

14/n

14/n

FOLLOWUP

Since this thread seems to be helpful for others, I’ll add more as it comes up.

Some of us are seeing significant rises in component prices from those who hoarded with the intent to resell. Colin here was quoted a 60x jump in price. https://abs.twimg.com/emoji/v2/... draggable="false" alt="😭" title="Laut schreiendes Gesicht" aria-label="Emoji: Laut schreiendes Gesicht">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😭" title="Laut schreiendes Gesicht" aria-label="Emoji: Laut schreiendes Gesicht">

15/n https://twitter.com/colinoflynn/status/1391788417017651202">https://twitter.com/colinofly...

Since this thread seems to be helpful for others, I’ll add more as it comes up.

Some of us are seeing significant rises in component prices from those who hoarded with the intent to resell. Colin here was quoted a 60x jump in price.

15/n https://twitter.com/colinoflynn/status/1391788417017651202">https://twitter.com/colinofly...

Read on Twitter

Read on Twitter