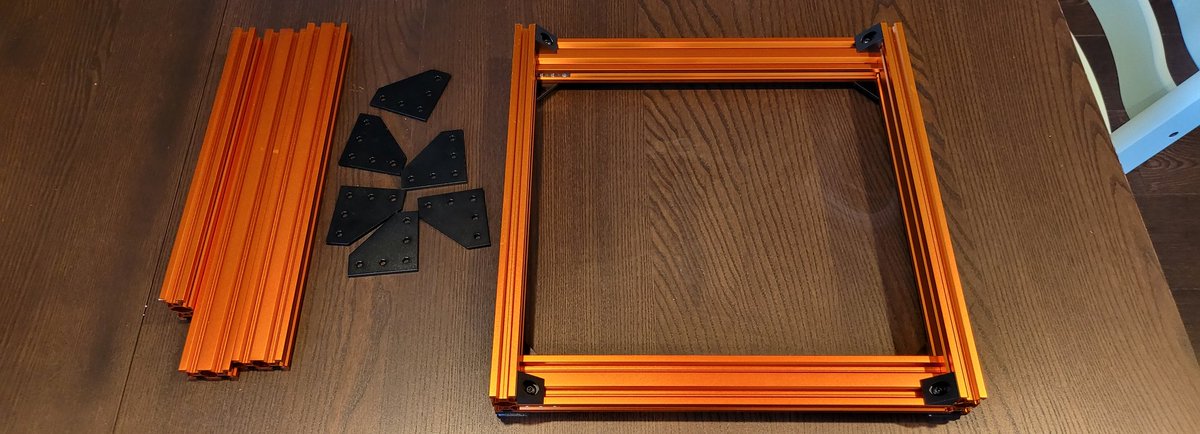

Putting together a new 3d printer, starting with a Prusa bear upgrade 2.1 frame. Very satisfying process, and I learned that aluminum extrusions are a fantastic primitive. I think I& #39;ll pick components as I go instead of taking apart my first prusa, and document the process here.

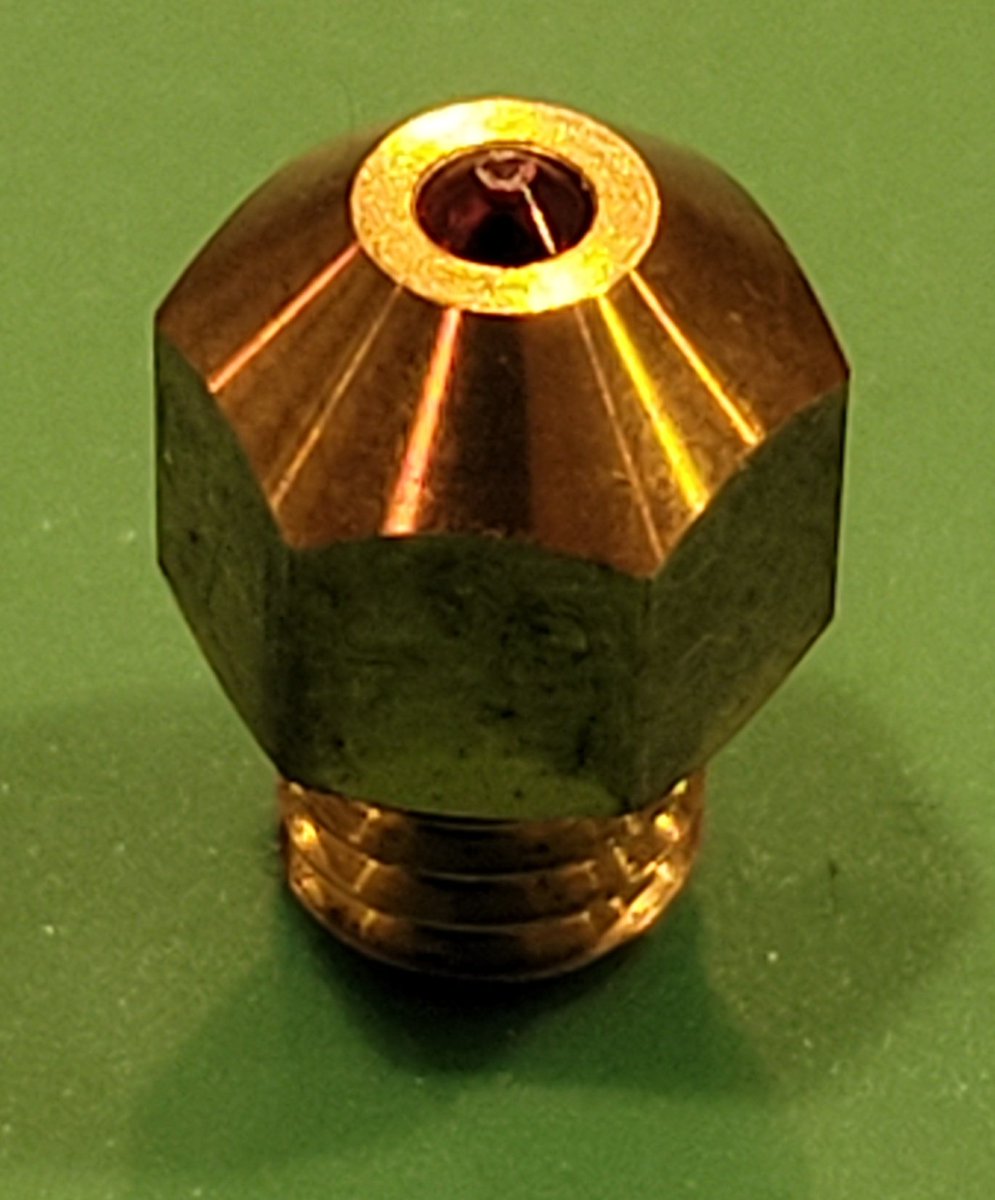

OK, so, here are some more bits that are going into this printer. First and foremost, an Olsson Ruby nozzle. It& #39;s an artificial ruby, but still, totally unnecessary impulse purchase from a few months ago. Might as well put it to use.

Next up, this maxiwatt integrated heater, block, and thermistor. When I discovered this puppy it was so obviously the way to go. The round shape also reduces surface area for the volume, limiting heat loss. And being compact is also an advantage for nonplanar prints.

Next up, the incredible bondtech lgx. I have high hopes for this bad boy, especially when it comes to making the overall extruder compact but capable. Also note the slice engineering bimetallic heat break, hopefully will keep the maxiwatt heat away from the rest of the extruder.

In terms of part cooling, I& #39;m wondering if I can have a two for one by mounting a blower in reverse, so that its intake forces air through the extruder heatsink. Like so:

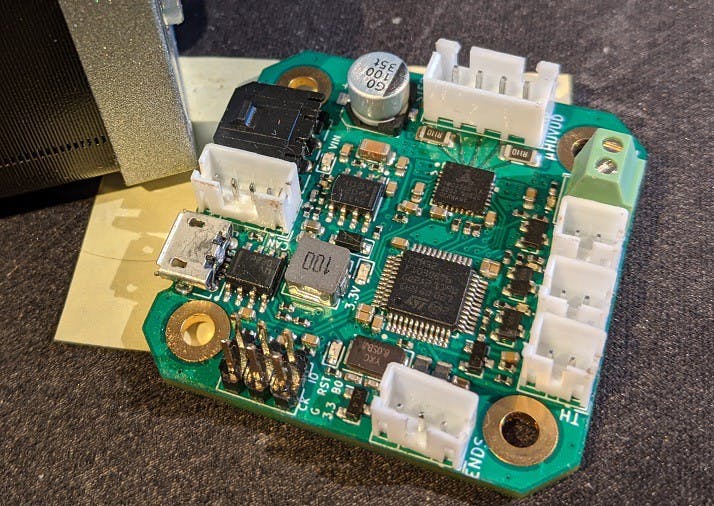

I& #39;ve also got this duet 3d toolboard that can help gather all the extruder peripherals into just a CAN bus, which I can hopefully then further combine with power, and maybe somehow pass the remaining two wires through the belt, so I can avoid having a cable harness entirely, but.

I& #39;ve since found some other boards that are smaller and have a profile that fits better with the LGX stepper motor, because the Duet is pretty chunky, especially compared with other options, which fit precisely. https://www.hackster.io/news/the-world-s-smallest-3d-printer-control-board-for-direct-drive-tool-heads-e9664502b60d">https://www.hackster.io/news/the-...

I& #39;d also like to avoid the ghastly z probes. Luckily there are options, from piezo to IR, which take hardly any space. Why make the extruder small? No big reason, other than most extruders looking like cobbled together Rube Goldberg machines, and wondering what& #39;s possible.

If I have my way, the main board for this puppy will be a balenaFin running Klipper on balenaOS. It& #39;s electronics are much more sturdy, and it runs on 12v/24v so there& #39;s no additional conversion needed to support a pi. https://www.balena.io/fin/ ">https://www.balena.io/fin/"...

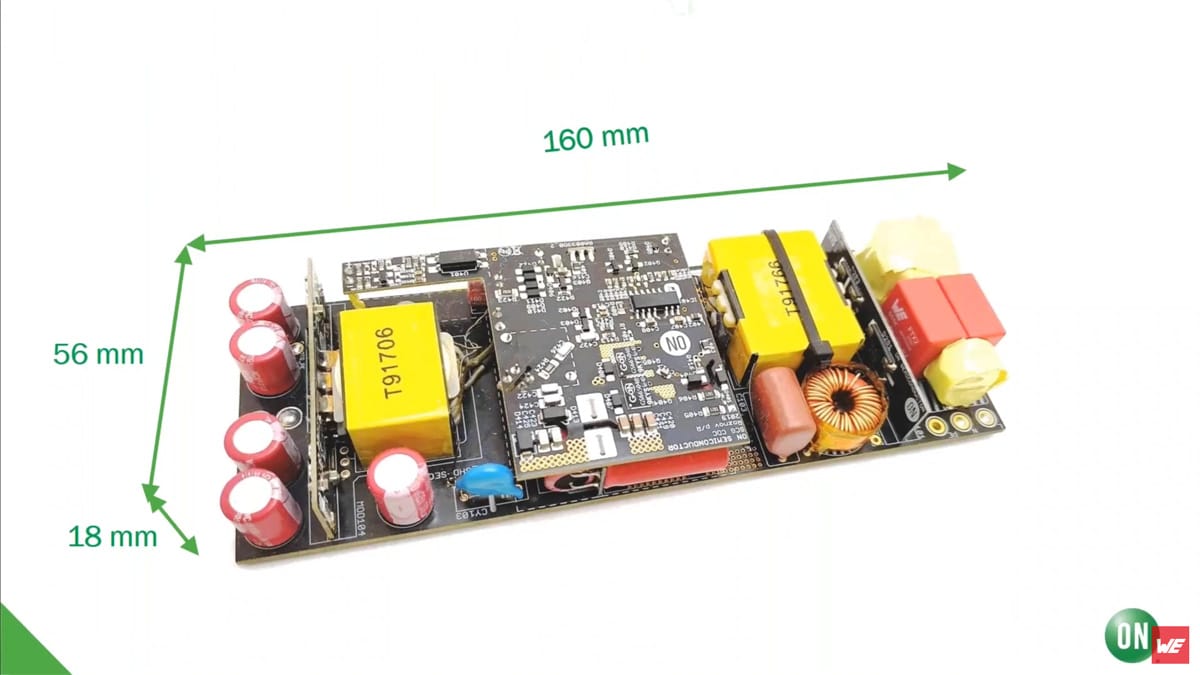

For a PSU, I am hoping to use some of this new compact GaN magic instead of the typical massive noisy boxes. This is what a 300w GaN PSU might look like, which is larger than the standard 250w that comes with the prusa. https://eepower.com/new-industry-products/300w-gan-based-ultra-high-power-density-ac-dc-adapter-reference-design/">https://eepower.com/new-indus...

I must note that most of these parts are silly expensive for what they do. I& #39;m mostly messing around trying to learn more about making my own printer, buying semirandom stuff during lockdown, and reliving my teens, when we would fantasize about making custom PCs...

... with handpicked peripherals we couldn& #39;t afford. 25 years later, I don& #39;t build my own PCs anymore, but those $TSLA gains have to go somewhere, so might as well "invest" it on something that might teach me sth.

I do have some interesting directions in mind for this project, ones more interesting than simple maaturbarory summing of parts, but I& #39;ll describe more if I end up going there. For now I just want to complete this bad boy, which means deciding whether linear rails are worth it.

Oh yeah, and I want to try to make the cabling as invisible as possible, which means possibly passing them through the extrusions among other dirty tricks, though bear upgrade folks don& #39;t seem to suggest this approach.

BTW, on the electronics front, if we& #39;re trying to avoid another main board in the mix, we can push more electronics all the way to the stepper, perhaps gaining some closed loop functionality to boot? https://makersportal.com/blog/raspberry-pi-stepper-motor-control-with-nema-17">https://makersportal.com/blog/rasp... or https://www.amazon.com/dp/B07RRSZPZK/ref=cm_sw_r_cp_apa_glt_fabc_8W3FQ1YVN662D8JHAJXF?_encoding=UTF8&psc=1">https://www.amazon.com/dp/B07RRS...

Read on Twitter

Read on Twitter