Time I think for another knife restoration thread.

I bought an old and rusty Nakiri on ebay. Here is my Nakiri.

I bought an old and rusty Nakiri on ebay. Here is my Nakiri.

I bought my Nakiri for three reasons:

1.) I knew and trusted the seller.

2.) The kanji (writing) are those of Kikuichi-monji, a store in Kyoto who have a reputation for working with some of the best knife makers in Japan.

3.) We will come back to reason three in a bit.

1.) I knew and trusted the seller.

2.) The kanji (writing) are those of Kikuichi-monji, a store in Kyoto who have a reputation for working with some of the best knife makers in Japan.

3.) We will come back to reason three in a bit.

First we need to remove the handle. This is done by putting the knife in an oven around 90-100 degrees for 10 mins, to soften the glue. Then holding the blade against a piece of wood and smacking the end of the wood with a hammer to knock the handle off.

Here is my nakiri now shorn of her handle and in her bath of vinegar, to remove the rust. About 10 mins here also.

And then after a coarse sanding.

And then after a coarse sanding.

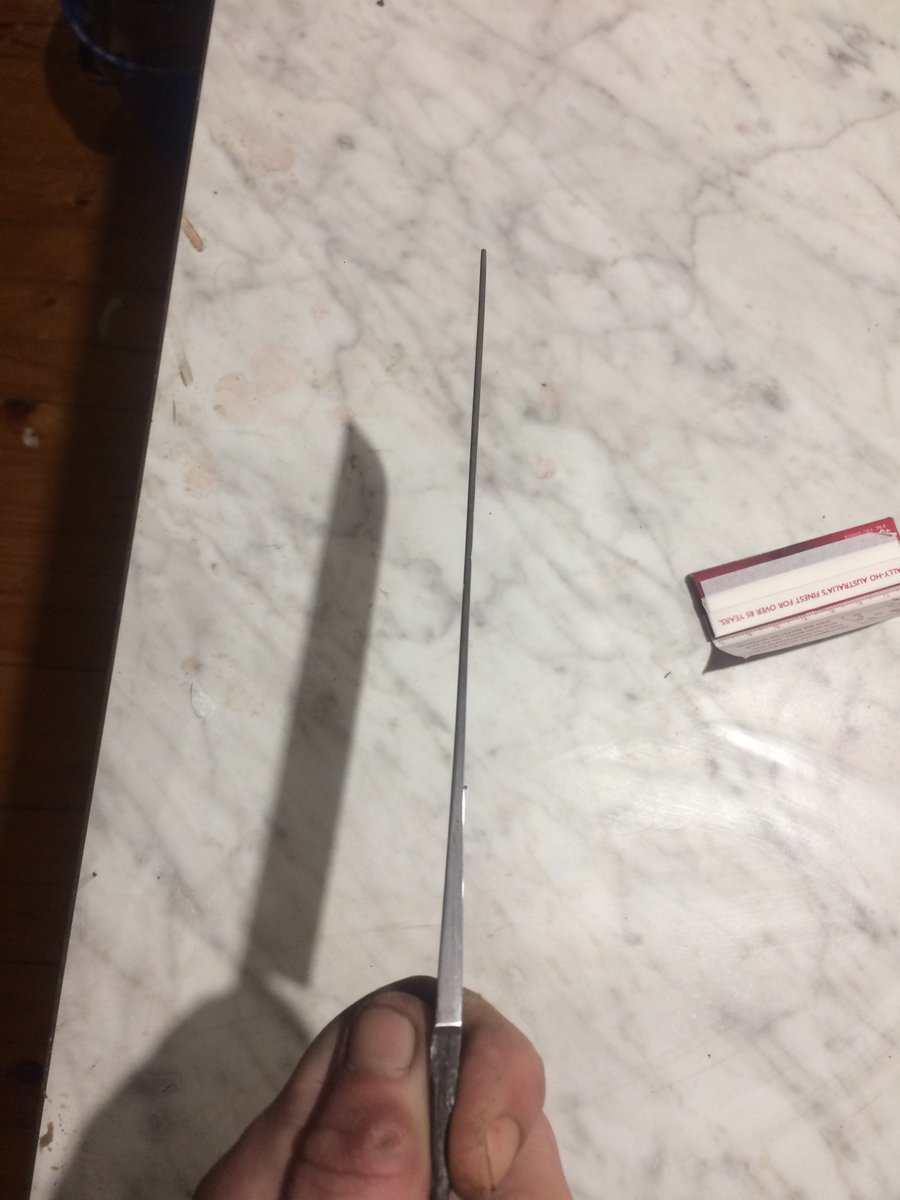

Now let& #39;s look at the grind of the knife...

The spine shows quite a pronounced early taper, before becoming thin and even for the large part of the blade. The 2nd (& #39;choil& #39;) picture shows the blade is nice and thin behind the edge, which is what we want, especially in a nakiri.

The spine shows quite a pronounced early taper, before becoming thin and even for the large part of the blade. The 2nd (& #39;choil& #39;) picture shows the blade is nice and thin behind the edge, which is what we want, especially in a nakiri.

I like the look of this knife, so I decide to try a full sharpening progression on the blade for fun, and try it out properly.

This is a very good knife.

This is a very good knife.

& #39;BUT WHAT& #39;S THE 3RD REASON YOU BOUGHT IT?!?& #39; I hear you cry.

The 3rd reason is because of the rather natty vintage blonde horn ferrule on the end of the original handle.

The 3rd reason is because of the rather natty vintage blonde horn ferrule on the end of the original handle.

Blonde horn I understand is the result of a kind of albinism, it is rarer than black horn, and certain types of blonde are quite sought after. It also changes colour and patinates as it ages.

And I want to try to incorporate this ferrule into the new handle.

And I want to try to incorporate this ferrule into the new handle.

The handle is what& #39;s called a & #39;d-shape& #39;. Along with oval and octagonal it is one of the most traditional styles of Japanese knife handles.

It& #39;s an incredibly comfortable shape, though asymmetric. This is for a right-hander.

It& #39;s an incredibly comfortable shape, though asymmetric. This is for a right-hander.

Now the horn is quite thin so I will also have to make the new handle d-shaped. Which I have not done before because I am an uncomplicated person, with vanishingly little woodworking ability.

But I am also cunning. And I have a plan up my sleeve...

But I am also cunning. And I have a plan up my sleeve...

If we saw off the end of the original handle, glue the horn back on, and sand the excess wood off, then we& #39;re left with a ferrule that we can glue onto a nice bit of elm burl. And it will at as a guide for the shape of our new handle.

The new ferule is also obviously perfectly drilled to accomodate the original blade.

Work smart, not hard.

Work smart, not hard.

Read on Twitter

Read on Twitter