ESP PUMP SIZING FOR UNCONVENTIONALS!! (4 days late I’m sorry!!)

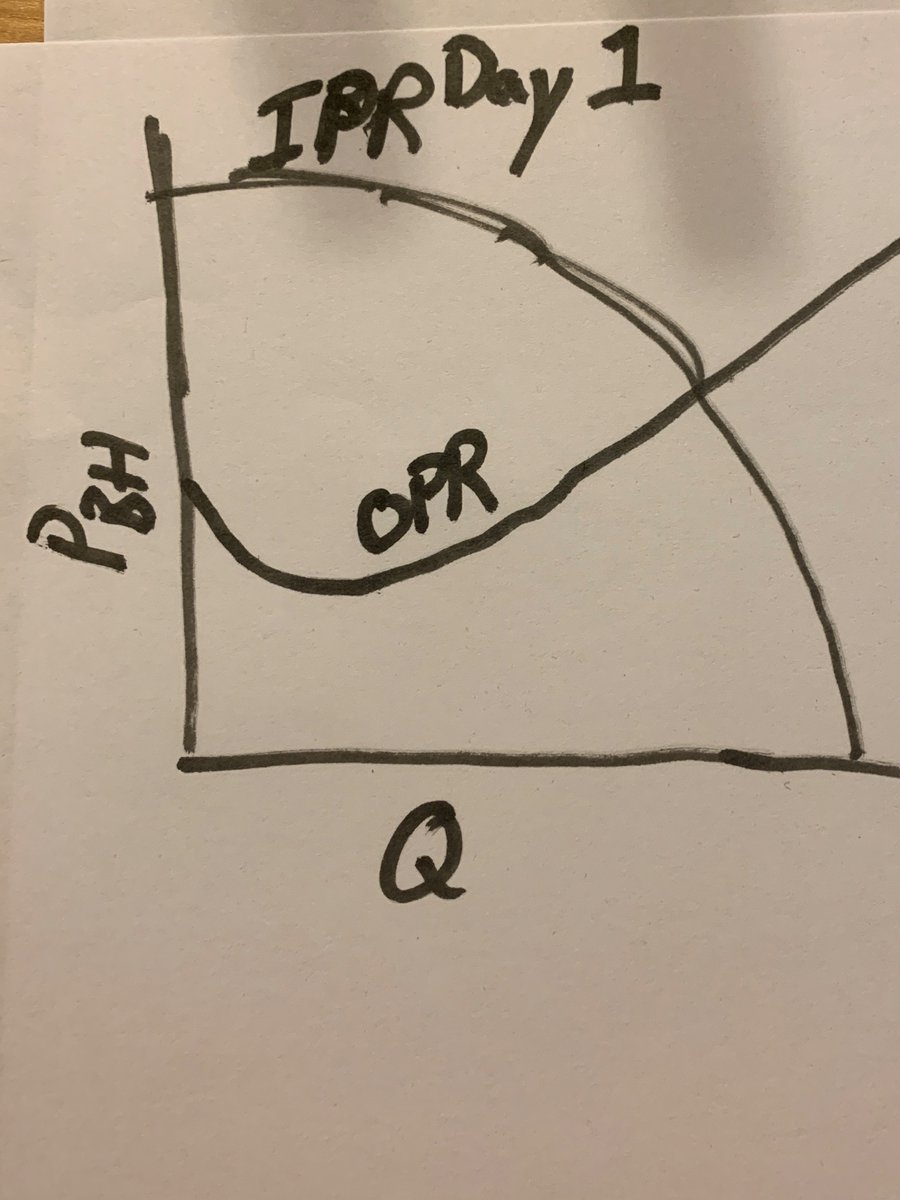

To understand sizing you need to know about IPR/OPR curves. The IPR curve most simply put is what the reservoir gives you in flow rate at every given bottomhole pressure.

On the very left side, bottomhole pressure = reservoir pressure. You don’t make any fluid to surface in this state. At the very right is absolute open flow -> minimum BHP for maximum flow rate

The OPR curve is a graph of the bottom hole pressure you need to surface fluid at any given flow rate. Pipe friction, hydrostatic pressure, and any other voodoo magic that causes pressure drops in the system causes the required pressure to go up at higher flow rates

Wherever IPR and OPR curves intersect, you get a flow rate for that system!

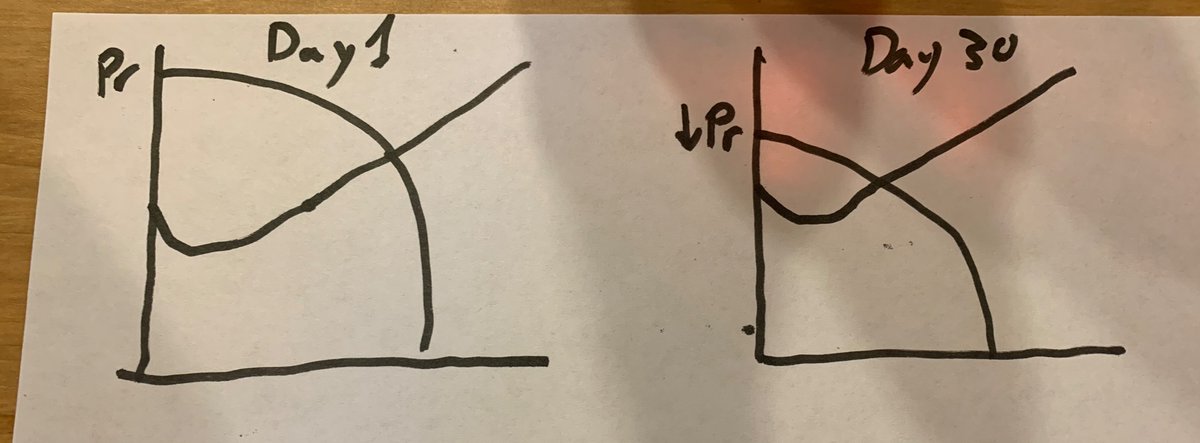

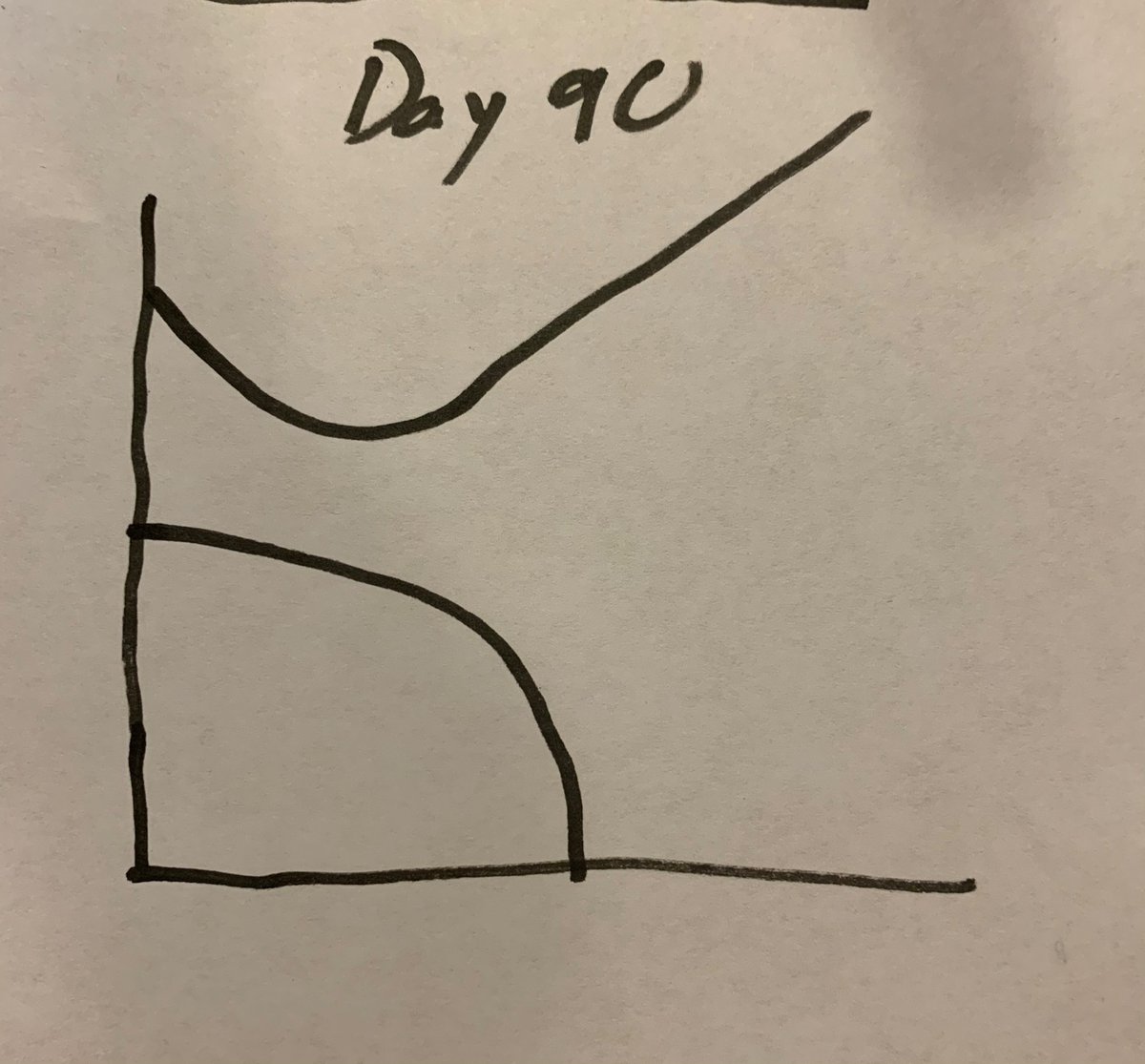

In shale, your IPR especially is very dynamic. As you draw down the reservoir, effective reservoir pressure drops and thus so does rate. Look at how the intersection rate declines as reservoir pressure depletes

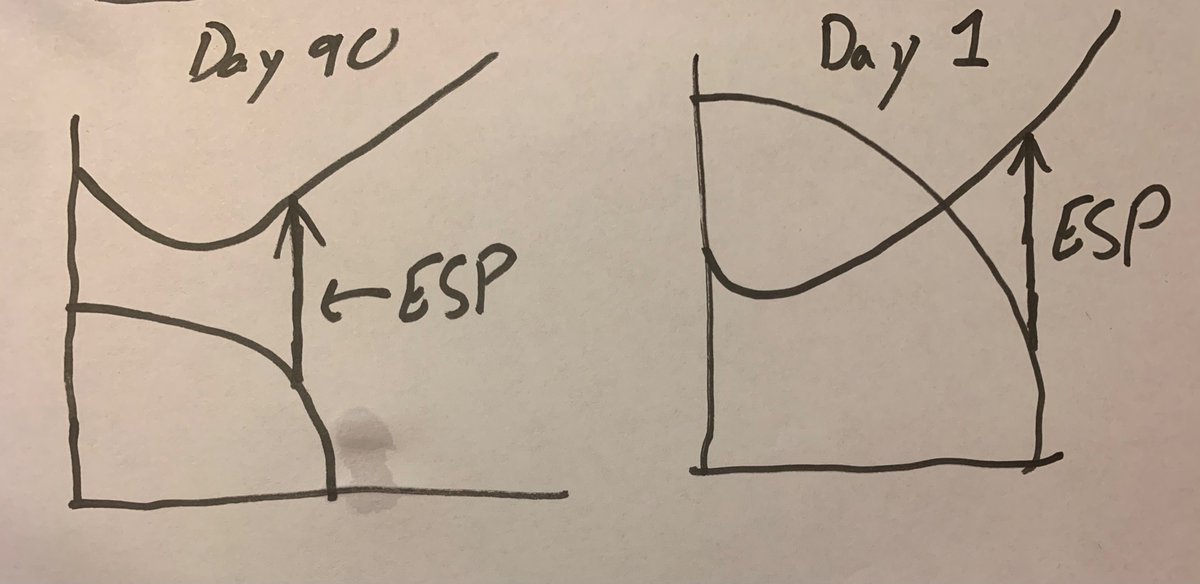

ESP TO THE RESCUE!!! (Sorry I spilled my water a bit) The ESP’s purpose is to bridge the gap between your desired flow rate on the IPR curve and the pressure required on the OPR curve

Now how are ESPs sized? They first are sized by the flow rate you want through the ESP to prevent excessive thrust in either direction, and then the pressure that the ESP needs to achieve is sized through picking the right # of stages.

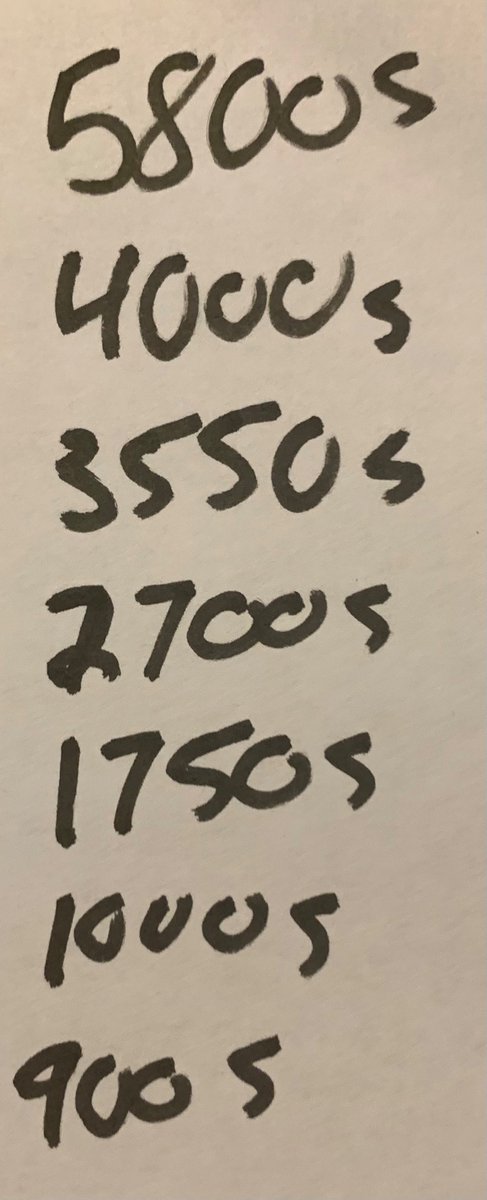

ESP stages are sized by their BEP (best efficiency point) flow rate. This picture contains many of the common sizes used on unconventional wells today. Typically the entire system is referred to by what pump BEP you ran in hole.

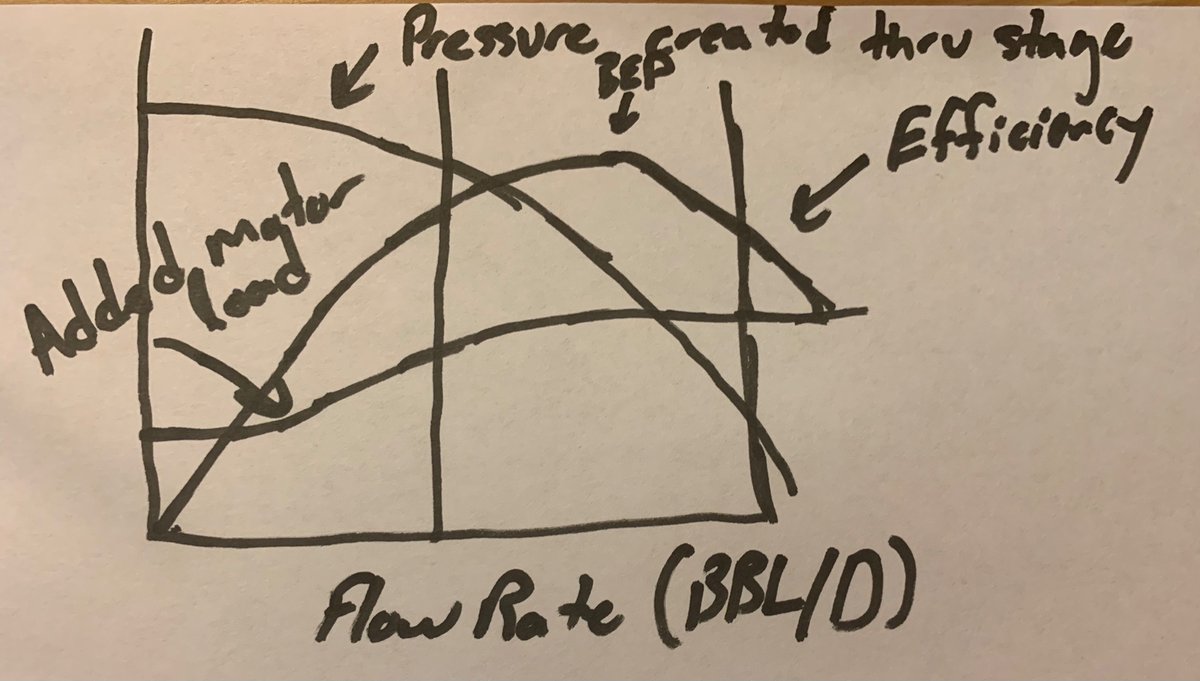

Curves for individual stages typically look like this. The pressure generated by each stage at a given rate, and the vertical lines indicating the optimal range of rates for the stage are the 2 most important things to keep in mind. Move left of the left line and you

Are now in a high downthrust state. Move right of the right line and the pump is in upthrust. Both states are sub optimal for long ESP run lives.

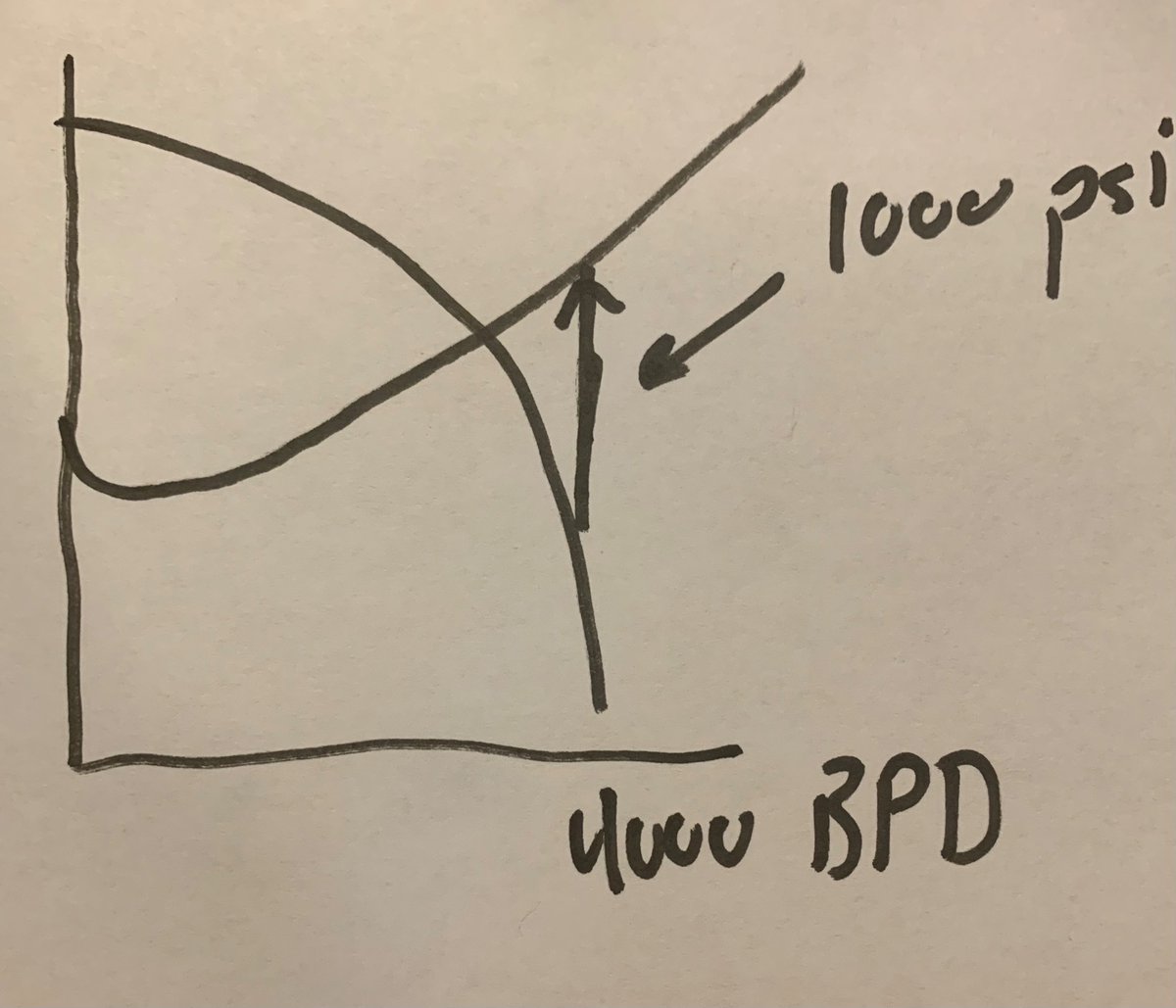

Lets put it all together now! My IPR/OPR curves say that I need 1000 psi of added lift to get my well to make 4000 bbl/day.

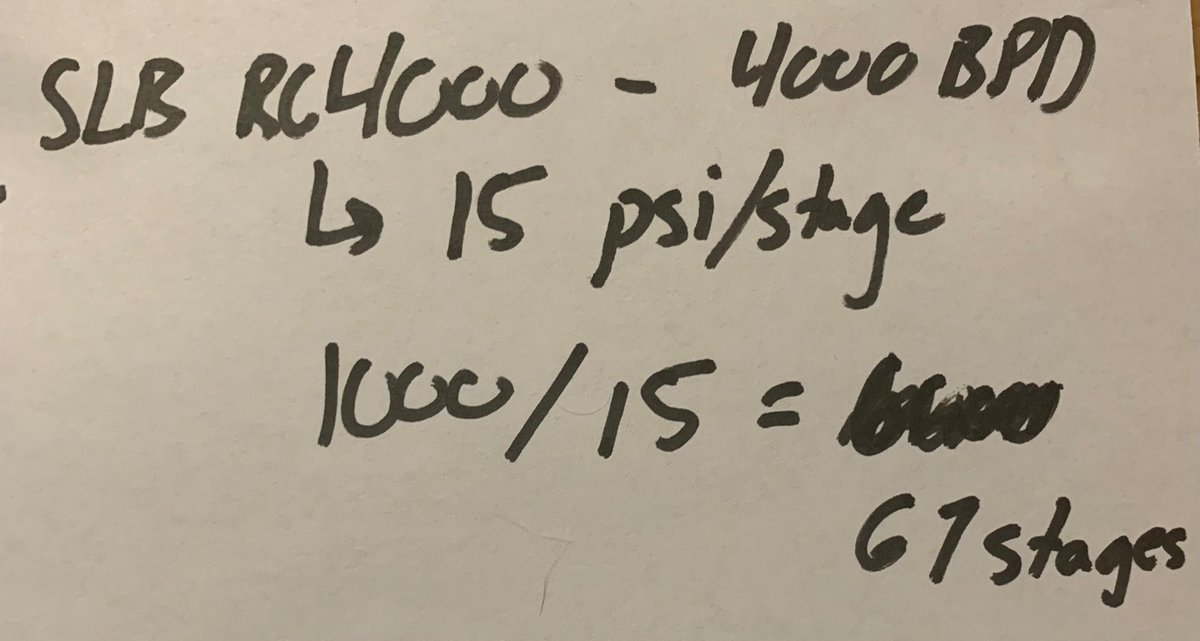

SLB wants to sell me an RC4000 pump (incredible pump btw) and lets say the pump curves will deliver 15 psi/stage at that rate. If I wanted a pump that could get me that needed pressure, I would need to install 67 stages of RC4000.

Now that we know the very basics, it’s a lot harder than this and there’s more to come on the design side! If you missed the first thread, gain some perspective here: https://twitter.com/bigD_oil/status/1312383936115376128?s=20">https://twitter.com/bigD_oil/...

Read on Twitter

Read on Twitter