BEV AUTOMAKERS BATTERY STRATEGY

Tesla may be the only significant BEV automaker using cylindrical cells

Suddenly that choice has become real critical to success in making and selling BEVs

WHY ?

Tesla may be the only significant BEV automaker using cylindrical cells

Suddenly that choice has become real critical to success in making and selling BEVs

WHY ?

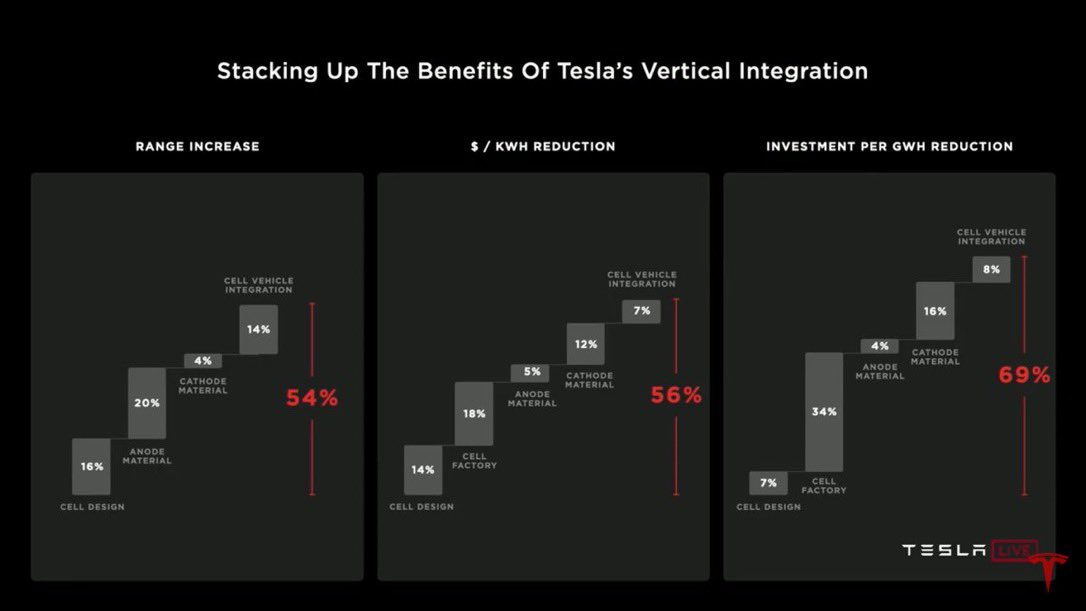

Tesla showed a whole range of benefits that they expect to achieve with their new Battery Manufacturing 2.0 initiatives

But some really important aspects of those innovations are only available to users of cylindrical cells

But some really important aspects of those innovations are only available to users of cylindrical cells

Particularly

- transverse current flows aka tabless electrodes

- larger cans

- structural battery packs that rely on the battery cans for honeycomb reinforcement of their strength

These account for :

- 30% Range increase out of 54% total

- 21% Cost decrease out of 56% total

- transverse current flows aka tabless electrodes

- larger cans

- structural battery packs that rely on the battery cans for honeycomb reinforcement of their strength

These account for :

- 30% Range increase out of 54% total

- 21% Cost decrease out of 56% total

If you are a BEV manufacturer you cannot directly access these benefits if you do not use cylindrical cells and have the degree of supply chain integration needed to upgrade to these innovations

You are not likely to admit it in public, but you have suddenly become both cost and range disadvantaged because the playing field has changed

Of course there will be efforts to overcome this disadvantage for users of pouch cells and prismatic and blade formats

Of course there will be efforts to overcome this disadvantage for users of pouch cells and prismatic and blade formats

And given enough time they may be able close the gap a bit

But time is not a free resource

By the time that today’s v1.0 Manufacturers catch up to v2.0 for their products, Tesla will already be at v3.0

If you doubt me let’s agree to meet at Battery Day 2025 and discuss

But time is not a free resource

By the time that today’s v1.0 Manufacturers catch up to v2.0 for their products, Tesla will already be at v3.0

If you doubt me let’s agree to meet at Battery Day 2025 and discuss

Read on Twitter

Read on Twitter