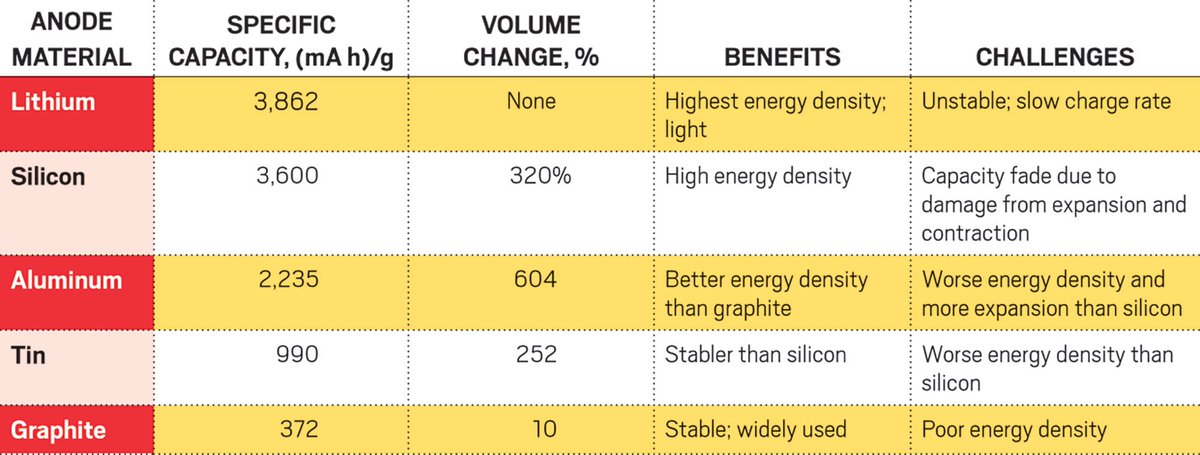

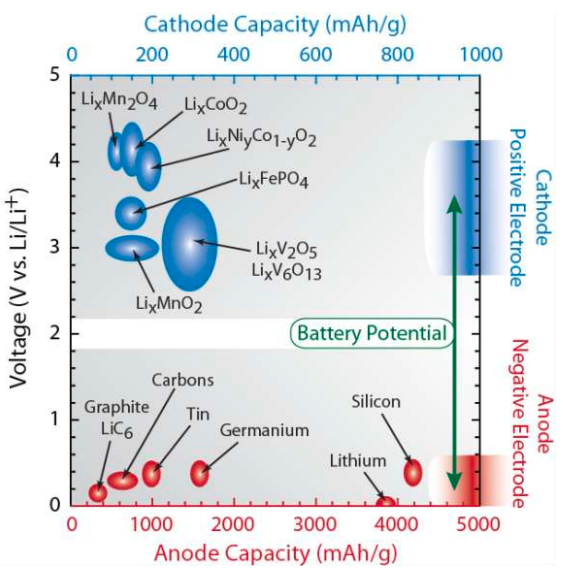

With regards to the speculation of silicon nanowire anodes: it should be stressed that silicon has nearly the specific capacity (mAh/g) of lithium metal itself. But some caveats.

1) This is only concerning the anode mass density - not net cell mass density, or volumetric.

1) This is only concerning the anode mass density - not net cell mass density, or volumetric.

2) Silicon is about 0,2V less than lithium metal, and 0,1V less than graphite. While this is not a massive difference, it does *slightly* temper its benefits.

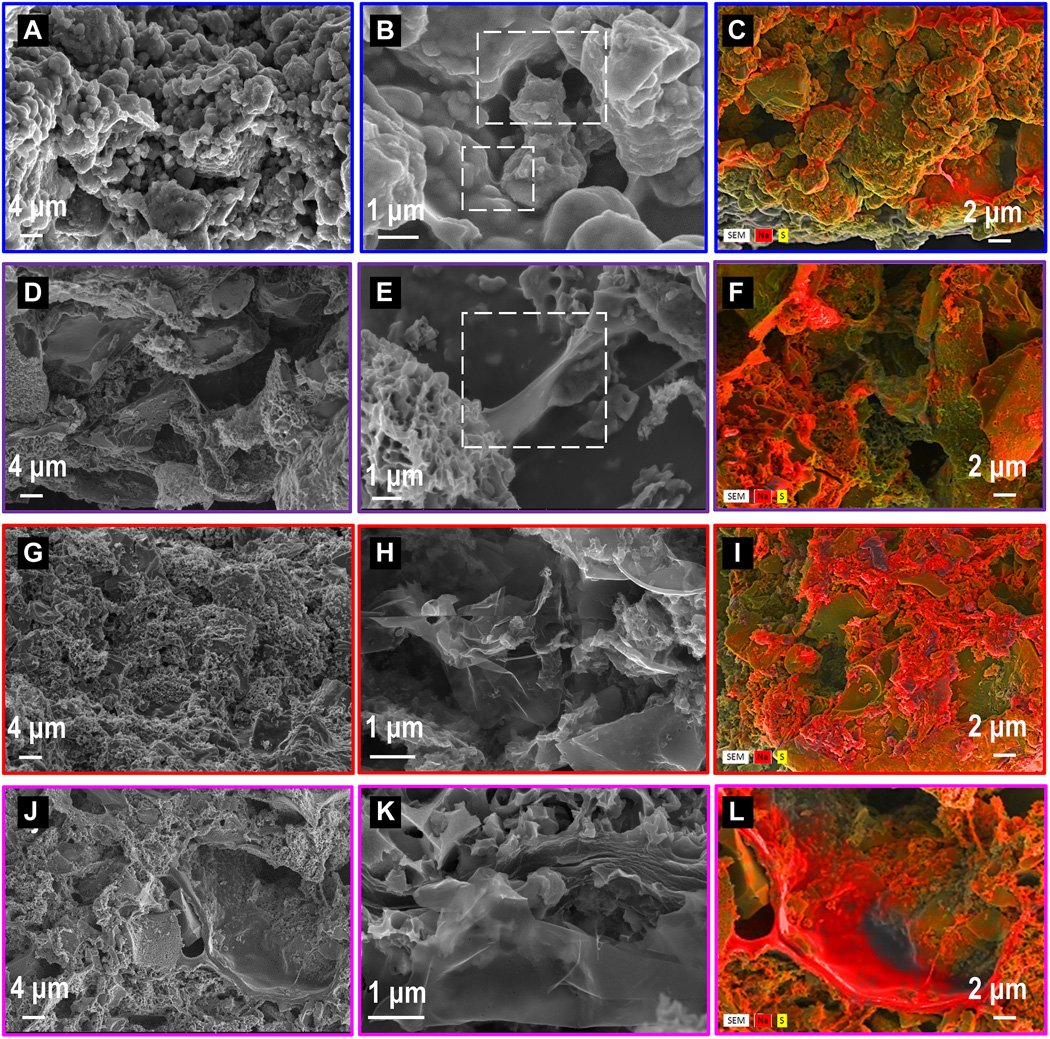

3) Historically, high-Si / low-C anodes have been plagued by three problems: microcracking, electrical separation from the anode current collector, and damage to the protective SEI. One presumes that this has been solved if Tesla is to employ it.

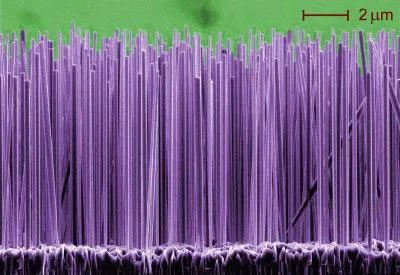

3a) Silicon nanowires themselves have long been proposed as a way to limit microcracking, as lithium can intercalate along their entire length, with only short distances to migrate within the nanowires, leading to more even internal pressures.

3b) Given Tesla& #39;s presumptive switch to dry manufacturing, and its nature of forming bonds more like tack welds than surface-slathering strings, this may well allow for more reliable current collector bonds.

3c) There is evidence from Tesla& #39;s Kato Road materials list that Tesla might possibly be looking at the creation of a durable titanate-based synthetic SEI rather than relying on passive formation of the SEI in the final electrolyte formation.

For now, however, this is mostly speculation - including the very premise of a silicon nanowire anode. But - if true - the benefits would be massive. Nearly to the degree of silicon metal anodes.

Now, as for the cathodes... ;)

Now, as for the cathodes... ;)

ED: lithium metal anodes

Read on Twitter

Read on Twitter