Part 8 of my Running Gear series, today a short look at track furniture. The series is looking at all the bits of tracked vehicle mobility and started here ( https://bit.ly/30596QZ )">https://bit.ly/30596QZ&q... if you want to follow the threads.

Usual disclaimer - this is Twitter, I don’t have much space and so some things are simplified or omitted for simplicity. This is a hugely complex science; I’m just giving a flavour of the considerations inherent in AFV design. With that out the way…

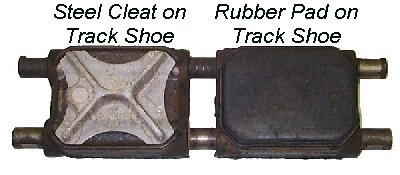

By track furniture, I refer to the add-on elements that can be fitted to most contemporary track to augment its grip in varying conditions. Whilst there are other oddities out there, I’m focusing the main two – rubber track pads, and steel grousers.

Most contemporary track (most Russian vehicles being a noteworthy exception) has rubber pads fitted to each link. These act like tyres – they cushion the ride, reduce vibration and noise on hard surfaces, and increase grip on smooth hard surfaces.

Without them, tanks will significantly damage the surfaces they move over. Particularly in training and operations in built up areas, unpadded tracks will devastate the infrastructure.

Like any rubber interface with the terrain, they wear at varying rates, though unlike car tyres its not uncommon to shed pads all over the place which can be an unwelcome discovery if you run over one on a dark lane near Bevington #ThanksForTheFlatTyrePagey

Pads can also shed when overheating due to hysteresis during high speed operations causes a so-called blowout and the pad critically degrades and falls away. Other general damage from terrain and obstacles can chip, cut or otherwise break up pads

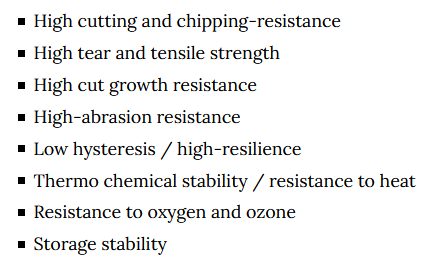

Like roadwheels, it requires some sorcery around rubber compound selection to meet demanding material requirements including wear longevity, thermomechanical stability, tear & tensile strength at high temp, resistance to burning, cutting, chipping, cracking & crack propagation

There is no & #39;best& #39; compound - much like car tyres (or any design concept really), you prioritise one characteristic at the expense of another. That said, hydrogenated nitrile rubber (HNBR) has been shown to have abrasion resistance is about 6-7x higher than other compounds

Grousers are a tank’s version of snow chains. These are usually carried on the exterior of a tank that anticipates ice being encountered and when installed are fitted in place of the pads at set intervals that vary by user and vehicle

They simply bite into the ground much harder and provide increased grip. Obviously, using these on tarmac or other surfaces will rapidly wear the grouser and will tear the surface to shreds

Worth a note that developments in composite rubber track (CRT) continue, already good for up to 42t GVWW and as weight capacity increases present the opportunity to do away with all the maintenance and complexity of pads and grousers in all AFV

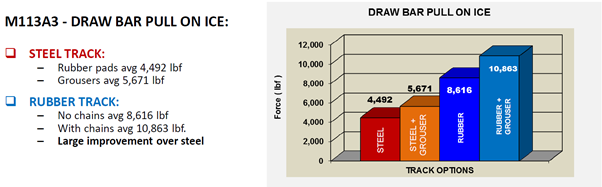

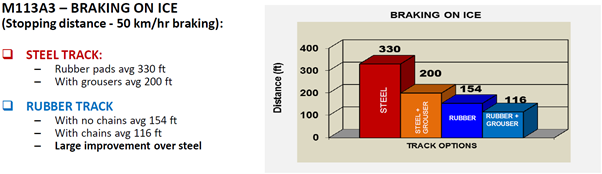

Here some @DefenseSoucy data showing that CRT without grouser chains can perform better than steel track with grousers fitted. Tractive performance is also better in essentially any condition, and there is no risk of pads sheedding as the entire track is one giant band of rubber

Quite as short one, but it’s only a brief topic. Next in the running gear series will be tracked vehicles steering /end #miltwitter #tanktwitter #AFVaDay

Read on Twitter

Read on Twitter