Since yesterday’s race car tech went over so well, let’s try another today. Actually have two things to talk about. Because of what happened to the 11 with ballast falling out, we will start there

First off, why do we have ballast on the race cars? Well a few reasons. First, to make minimum weight per the rules. Second, to get our weight percentages where we want them, and that can be complicated. Third, we want the weight as low as possible.

Let’s start off first with the minimum weights. Nascar in the last couple years has gone to a formula that includes drivers weight into the total amount at scales. So if a driver weighs 160#, and another weighs 190#, their cars are now able to be set for that.

This wasn’t the case for many years, really as long as I can remember. So driver A car now has to weigh 30# more than driver B. That’s to make the weight of a driver not matter as much in competition. It still does but just not as much

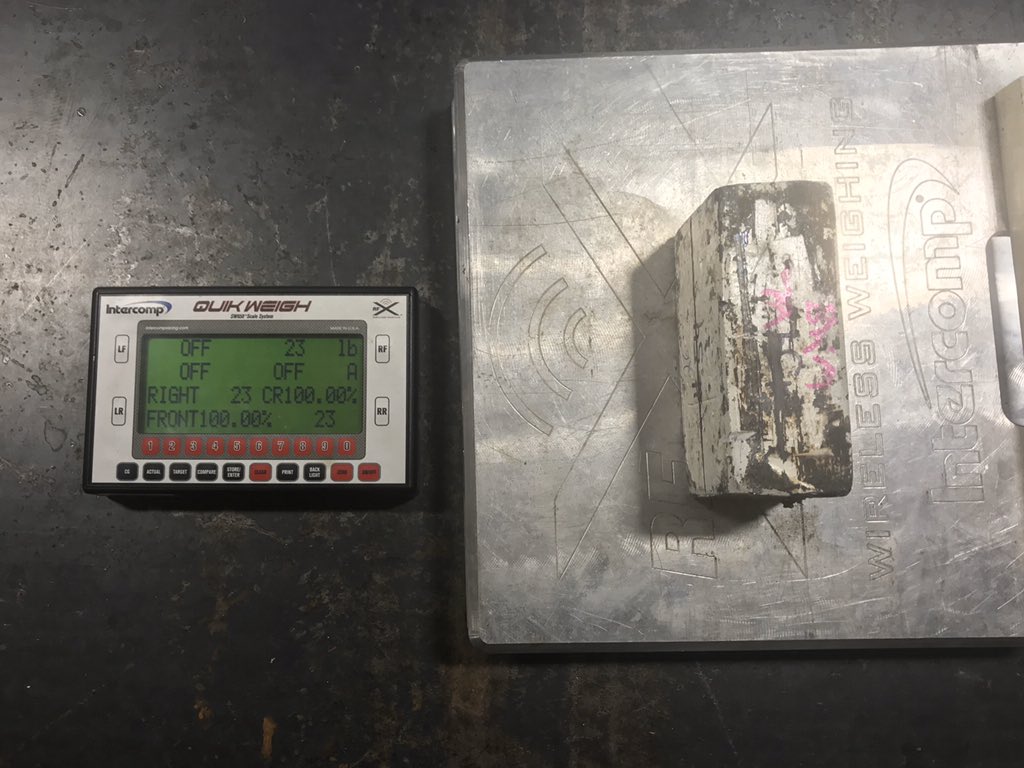

So with that said, you add ballast according to the rules to get as close to minimum weight as possible. Usually two kinds of ballast, lead or tungsten. Lead is lighter, but extremely cheaper to use. Issue is, it’s harder to get the weight % right with if you need it

Why is that? Well in nascar since the COT came about, Nascar changed the rules on where lead rails can be and not. So limited amount of room has forced teams to go the tungsten route to get things where they want them.

Same size but weighs a bunch more. So now you can get the weight % where you want it

Now the third reason is getting the weight lower. In racing there has always been an adage of the three L’s, low, light, and Left. There is rules on right to left weight percentages, but you try to max that out as much as possible.

Getting the weight down helps the center of gravity on the car. So let’s say you drive a tall truck and take a corner fast vs a small car. That truck leans over way more than the car. Same in racing. Lower the better.

So teams make the parts of the car above the frame rails as light as possible. Light weight dashboards, pedal assemblies, bolt lengths, I mean anything you can think of above that frame rail

It’s even gotten to the point teams will cut down the tungsten to lower it inside of the frame rail. A piece like this gets an aluminum block on top of it to make it the same size but the weight is lower

Teams will also use light weight headers but heavy exhaust systems. Why? Because the exhaust is lower than the frame rails. It’s all about getting it LOW.

In recent year, teams have added a frame rail in front of the sway bar tube. It had a double reason for it until the splitter pans got so big, it had been there for a little downforce. Now it’s primarily just for more front weight.

Some teams even use an insert inside of the actual sway bar. Trying to get front weight can be difficult

So with what happened to the 11 team, it’s easy to have happen. Nascar mandates years ago the front frame had to be capped off like this

So the only way in and out of that frame rail is they the back of the rail in front of the rear tires.

There is a bolt that holds everything in, and likely it was left loose enough to stay for qualifying but fell out right before the race. It’s a huge deal and by no means on purpose. We all know how big of a deal it is now and an area people don’t mess with. It’s a human error

So that’s it, all you ever wanted to know about weight ballast in a stock car. And maybe more than you wanted to know.

Read on Twitter

Read on Twitter