Raining pretty hard here in Mooresville and doesn’t look good for racing tonight. So, I went to the shop and took some pictures to talk a little about what I mentioned last night about the trucks and how they setup their springs.

From the mid 70’s until the early 2000’s, the front springs really didn’t change a whole lot. But, as teams started to learn how to travel cars, and keep the platform in place better, teams started demanding a better product.

This is an Lower A-frame from a truck in the late 90’s. Notice the bucket the spring sits in is pretty much flat and has a step in it for the end of the spring to sit in. Guys would even weld bolt on the end of the spring and drill a hole in the bucket for it to go thru

That was because the spring would just slide around in that bucket whenever it wanted to. Which would change the handling of the car unpredictably.

As springs started getting better, so did the buckets they sat in. By the mid 2000’s, spring we’re becoming so much better because of the alloys used and the parts you could get to hold them correctly. When coil binding started, teams were struggling to hold ride heights

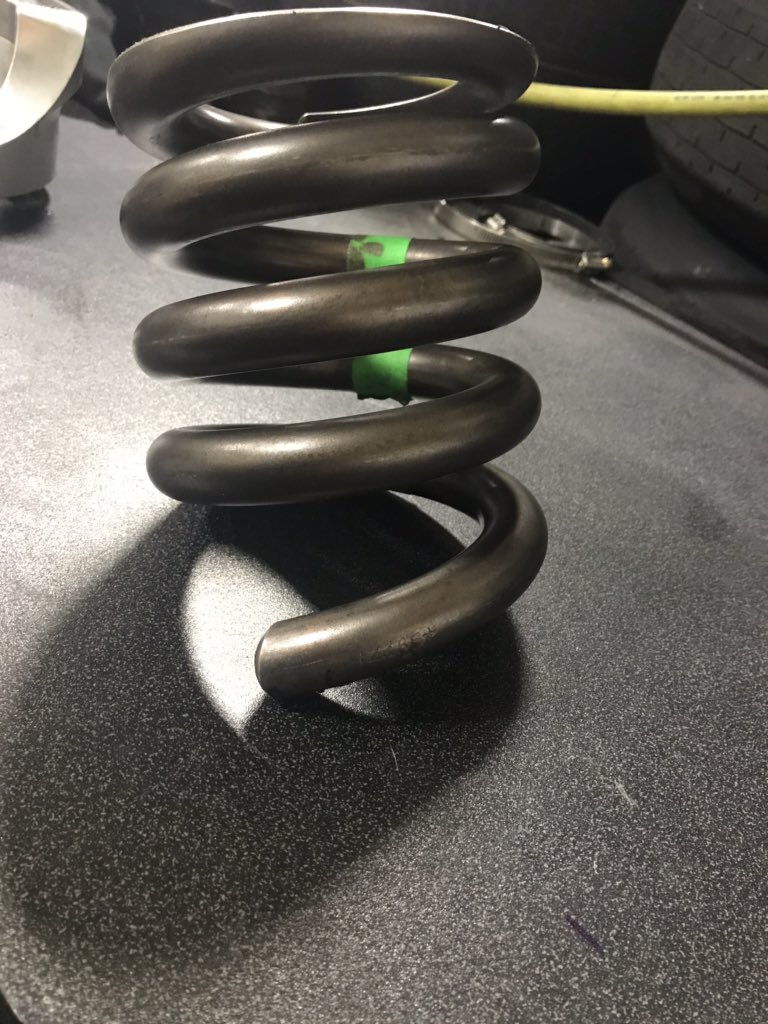

This is what an older spring used to look like. It was stuffer so it would hold the car up from the track

As time went by we figured out how to get the car to run lower with better parts. This forced engine builders to fix oil pan heights, body guys to raise fenders, chassis guys to raise crossmember heights and sway bar tubes. It created a whole mess but was a fun time

Then comes a new titanium alloy spring that changed a ton of thinking. Renton springs developed a better spring that would collapse after one use. They were way more expensive of course but cheaper than the fine for being too low post race

This was pretty much the standard way of running cars until the COT started. Then the whole world changed again

With it came bump stops. Coil binding all but ended. Some still did it but for the most part it was over. Until about 2011-2012

Then came something really weird. Pigtail springs. As you notice the spring is wound tight at the top but wider at the bottom. Resembling a pigs tail

Buckets also had to change so the spring would work right. Companies like ETG, Cagnassi, and Rush industries all made a version of this bucket

Basically the spring will hold itself up at ride heights to get thru tech, then as it gets load in the corners, it falls down to a lower height. This created a whole new problem on how to do this correctly and not blow the parts to pieces

If you watched the truck race last night, at the competition caution, trucks came in bottoming out on the track. Some put turns in the front while others were under the truck fixing parts that had broken.

The 51 had a part break, and it’s easy to have happen, that stopped the travel of the spring. They had to add spacer back to it to get the truck to not hit the splitter. The 13 added turns to the front of theirs, probably because they were coil binding the RF

This is the cool part, both ways are legal to run, and are an option the teams can still have to tune on their trucks. There is a ton to how it all works, and no one team does it the same. But, that’s what Racing is all about. Building a better race car/truck and going fast!

Read on Twitter

Read on Twitter