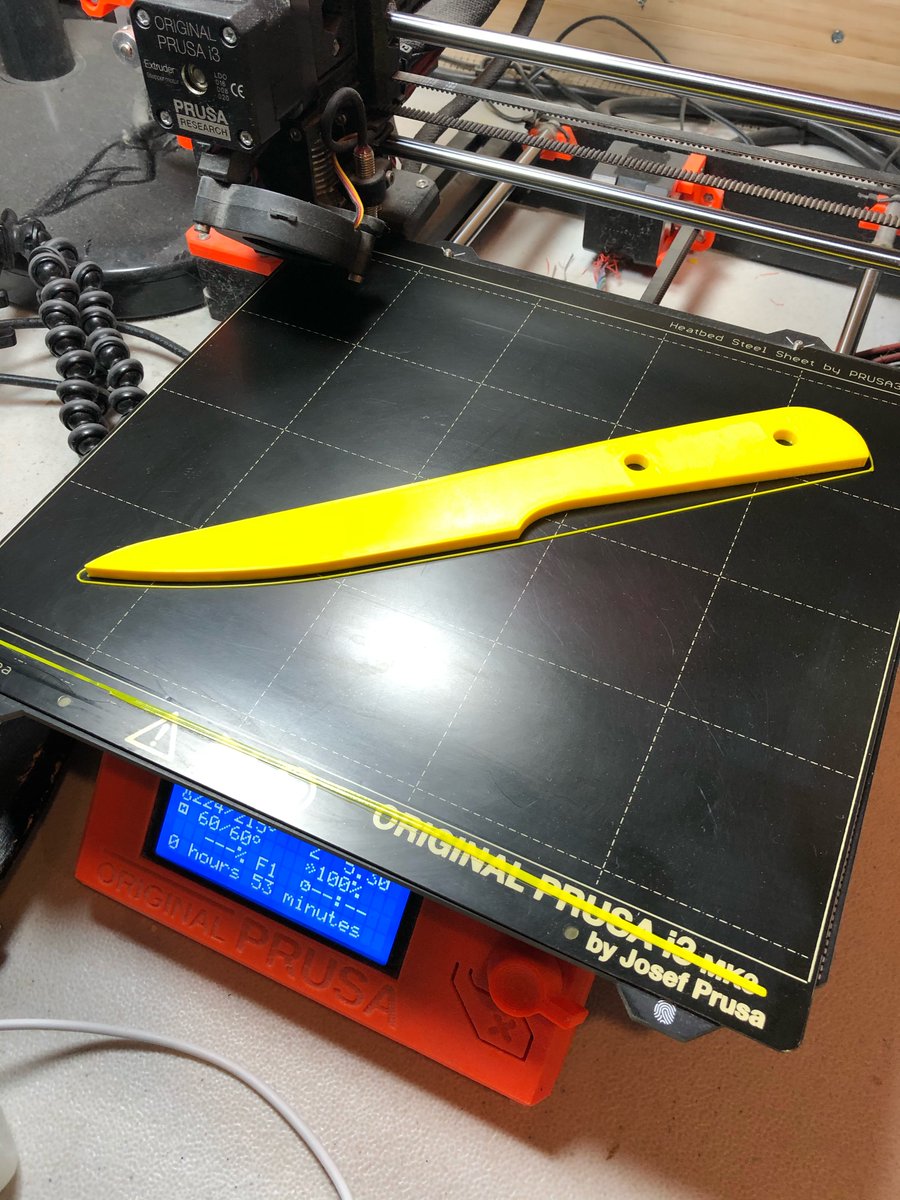

I’m pretty sure it will..... not cut.

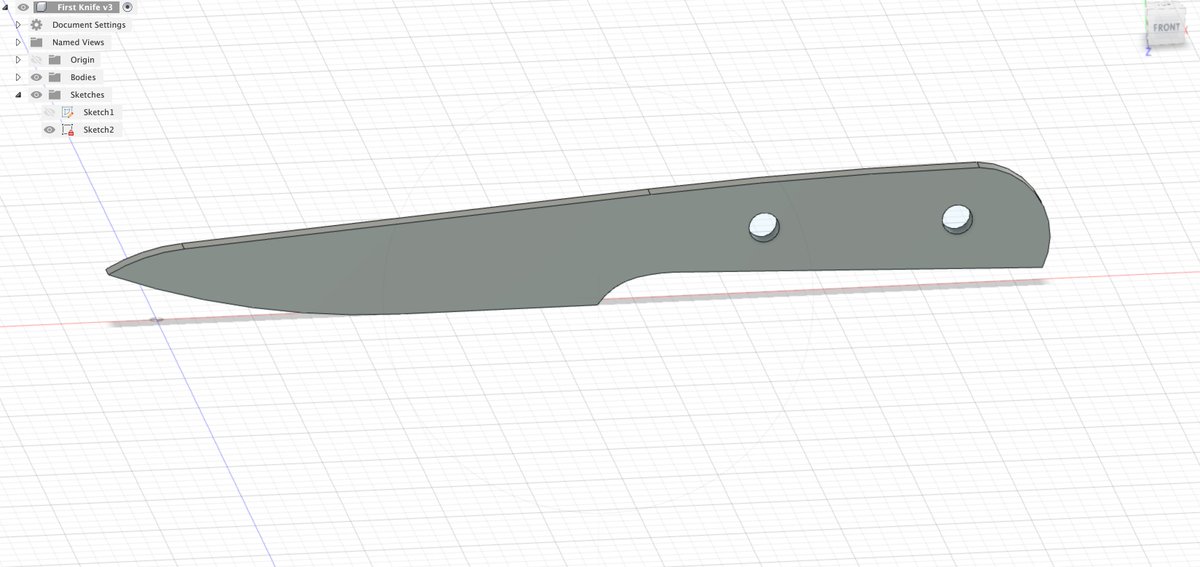

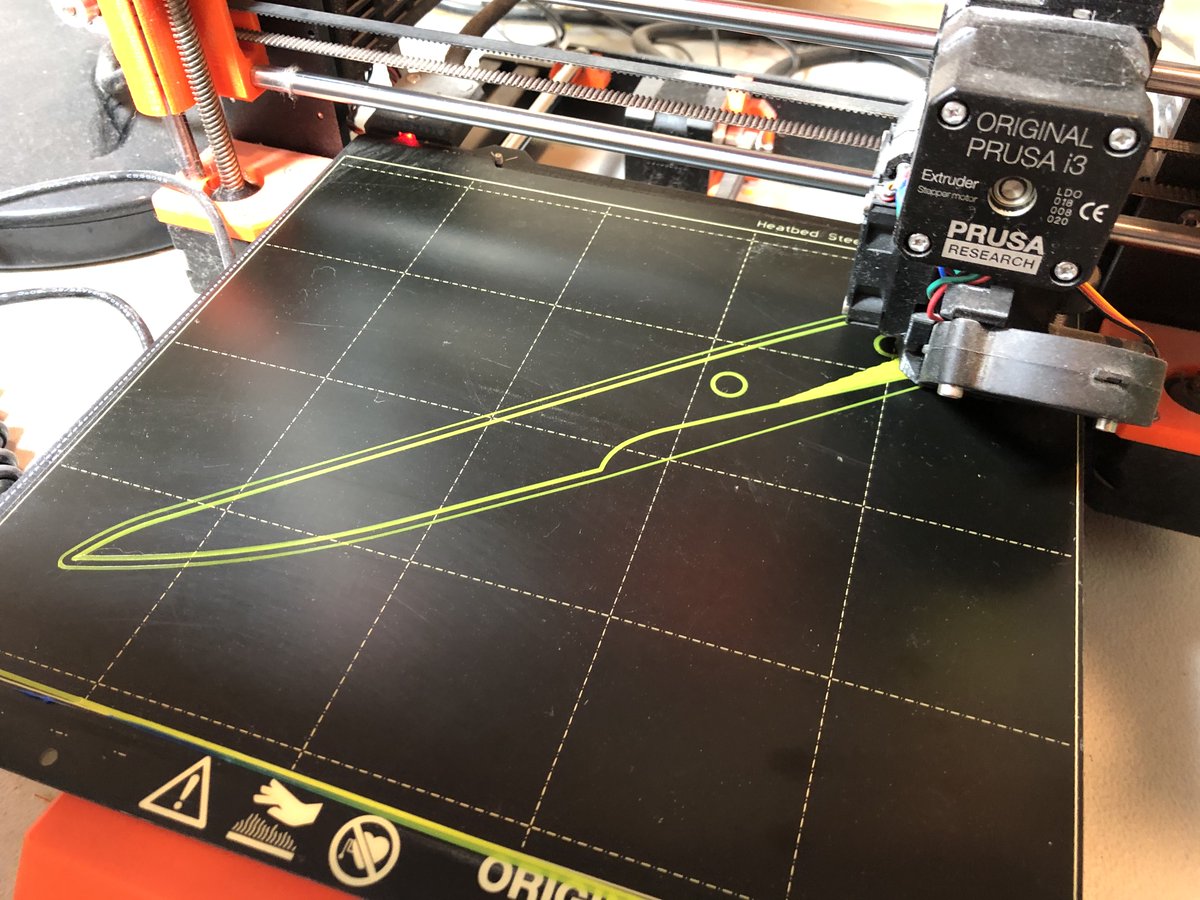

So anyway, I ordered a few things I didn’t already have in preparation for making this knife out of actual steel. I’ve never done anything quite like this before, so it should be interesting. Unfortunately it’ll probably be about a week yet before the things I need arrive.

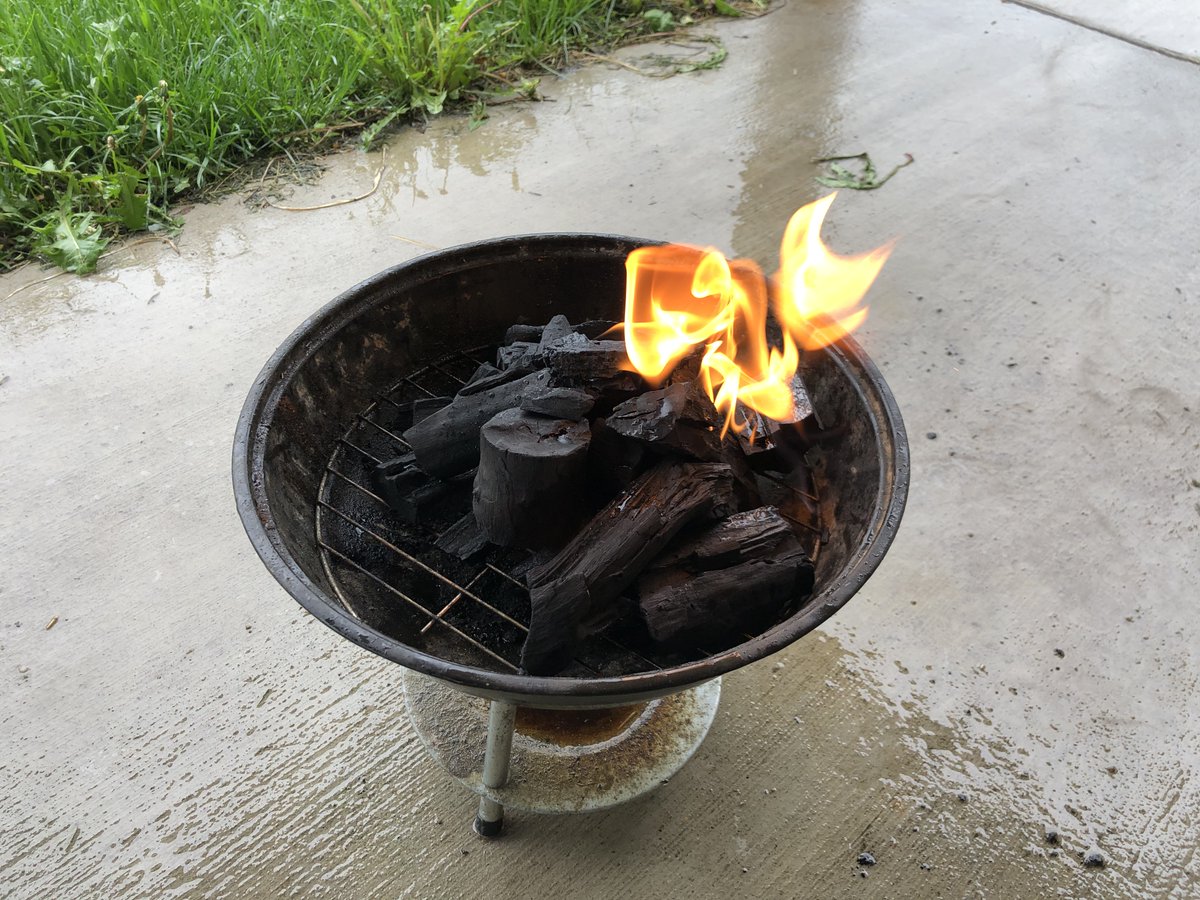

Not sure about heat treating yet. I might just try a charcoal “forge” using a grill or something like that when the time comes. Supposedly it can get hot enough if you constantly blow on it with a shop vac or whatever.

I don’t have an anvil or a real forge so I’m not creating my own billet of steel or anything crazy like that.

Yet.

Yet.

This is all @gedeon’s fault because he told me to watch Forged in Fire awhile ago and then the show had a big disclaimer about how “forging is dangerous” so obviously that got my attention.

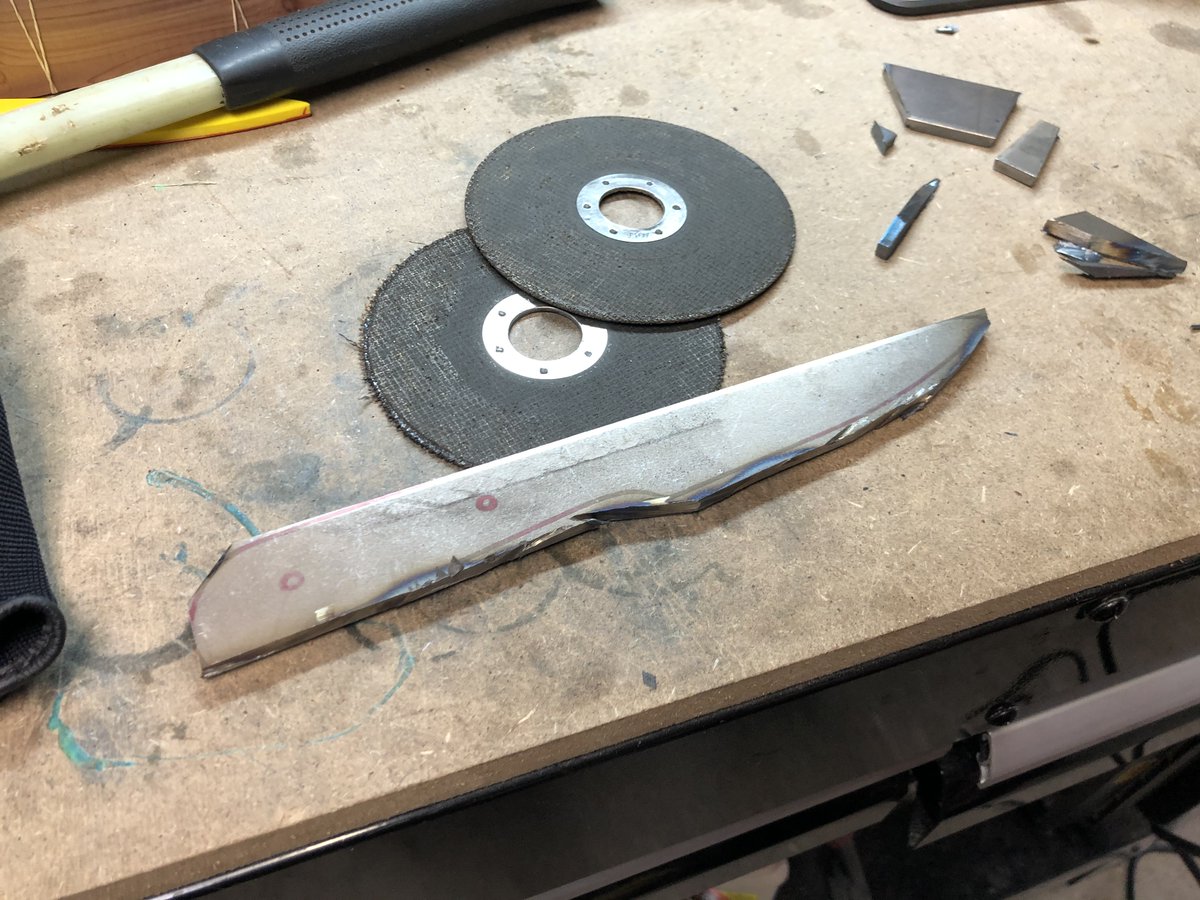

I got my steel for the knife project! I hope this isn’t too thick.  https://abs.twimg.com/emoji/v2/... draggable="false" alt="😛" title="Face with tongue" aria-label="Emoji: Face with tongue">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😛" title="Face with tongue" aria-label="Emoji: Face with tongue">

Steel is heavy.  https://abs.twimg.com/emoji/v2/... draggable="false" alt="😅" title="Smiling face with open mouth and cold sweat" aria-label="Emoji: Smiling face with open mouth and cold sweat">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😅" title="Smiling face with open mouth and cold sweat" aria-label="Emoji: Smiling face with open mouth and cold sweat">

Knife project update: I now have a grinder, some files, safety goggles, and hardwood for the handle! Pretty sure I have everything I need to get started on the main shaping part of the job. Still have to come up with something for heat treating but first I need to make the blade.

I should have tried to get an action shot with sparks flying everywhere, but that seemed a tad dangerous. I do like my fingers and would prefer they stay attached and intact. My garage shop smells like carbon now.

I built a contraption to hold the grinder on its side so I could work on the profiling and then attached a sanding wheel.

Here’s the profiled blade after a bit of grinding! Not sure how to evaluate it, but I think it’s decent for a first try without, I assume, the “proper” tools.

I tested it in a cardboard box despite it not actually being properly sharpened (or hardened) and... it will cut!

I tested it in a cardboard box despite it not actually being properly sharpened (or hardened) and... it will cut!

Ordered ear protection. That grinder is hella loud. Apple Watch said it hit 100dB. Ears still ringing a bit.

Sanded the knife by hand and drilled some holes for the handle attachment. I think the next step is heat treatment. Guess I’ll be building a hot charcoal fire this weekend and seeing what happens!

Built a quench tank with a piece of PVC with an end cap and the world’s worst stand - but it’s stable enough!

Unfortunately the actual heat treating step is currently on hold due to a tornado warning.  https://abs.twimg.com/emoji/v2/... draggable="false" alt="🌪" title="Cloud with tornado" aria-label="Emoji: Cloud with tornado"> Will probably get the charcoal fire started up in 20-30 minutes assuming we don’t blow away.

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🌪" title="Cloud with tornado" aria-label="Emoji: Cloud with tornado"> Will probably get the charcoal fire started up in 20-30 minutes assuming we don’t blow away.

Filled my quench and tank with vegetable oil. Tied a wire to the knife so I can fish it out of the hot coals once the rain stops. Soon there will be fire and heat!

Okay this forging thing is way too much fun.

Witness the power of this fully functional Weber Grill Forge!

Into the quench! There wasn’t any flare up but it made a nice little sizzling sound. After it cooled a bit, I scraped off some of the scaling.

And now.... the file test. I think it’s hard! @gedeon

Read on Twitter

Read on Twitter

" title="I got my steel for the knife project! I hope this isn’t too thick. https://abs.twimg.com/emoji/v2/... draggable="false" alt="😛" title="Face with tongue" aria-label="Emoji: Face with tongue">" class="img-responsive" style="max-width:100%;"/>

" title="I got my steel for the knife project! I hope this isn’t too thick. https://abs.twimg.com/emoji/v2/... draggable="false" alt="😛" title="Face with tongue" aria-label="Emoji: Face with tongue">" class="img-responsive" style="max-width:100%;"/>