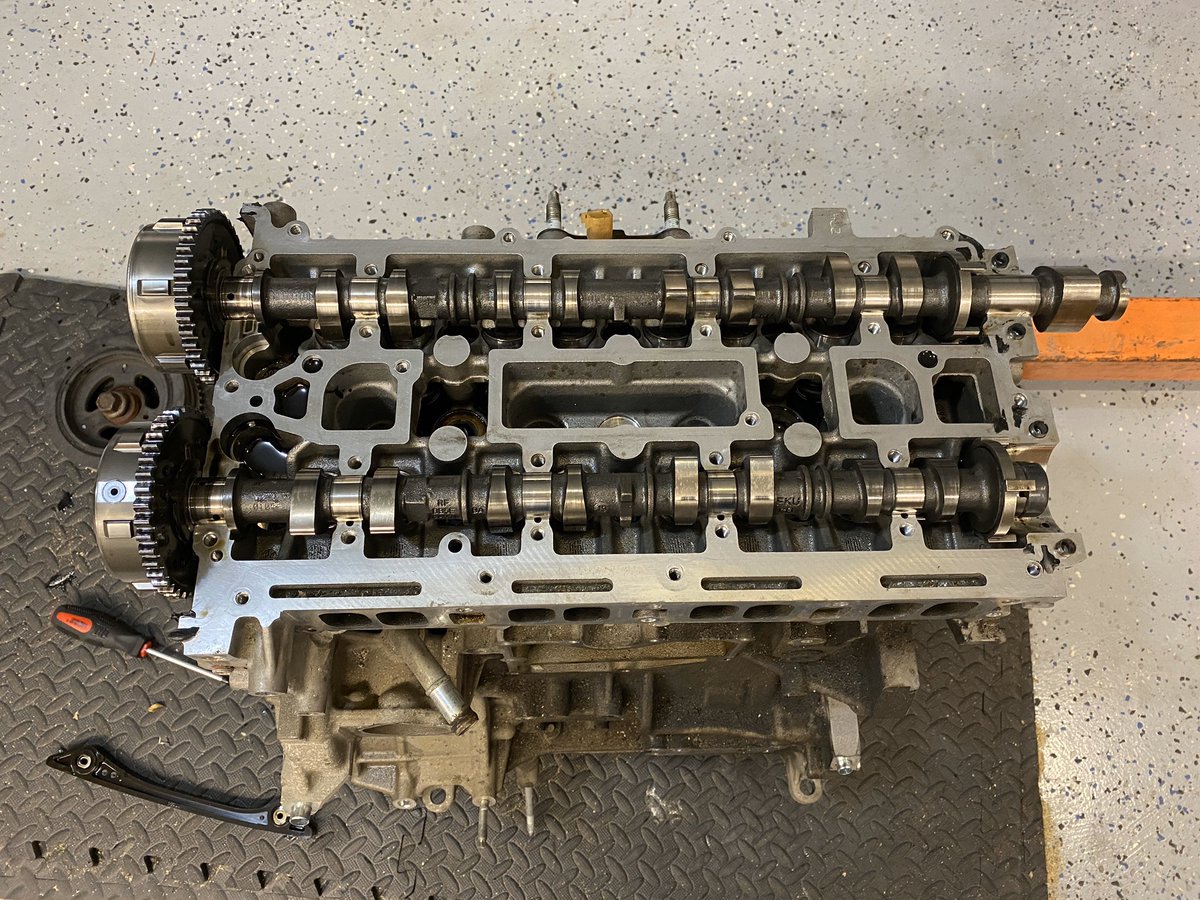

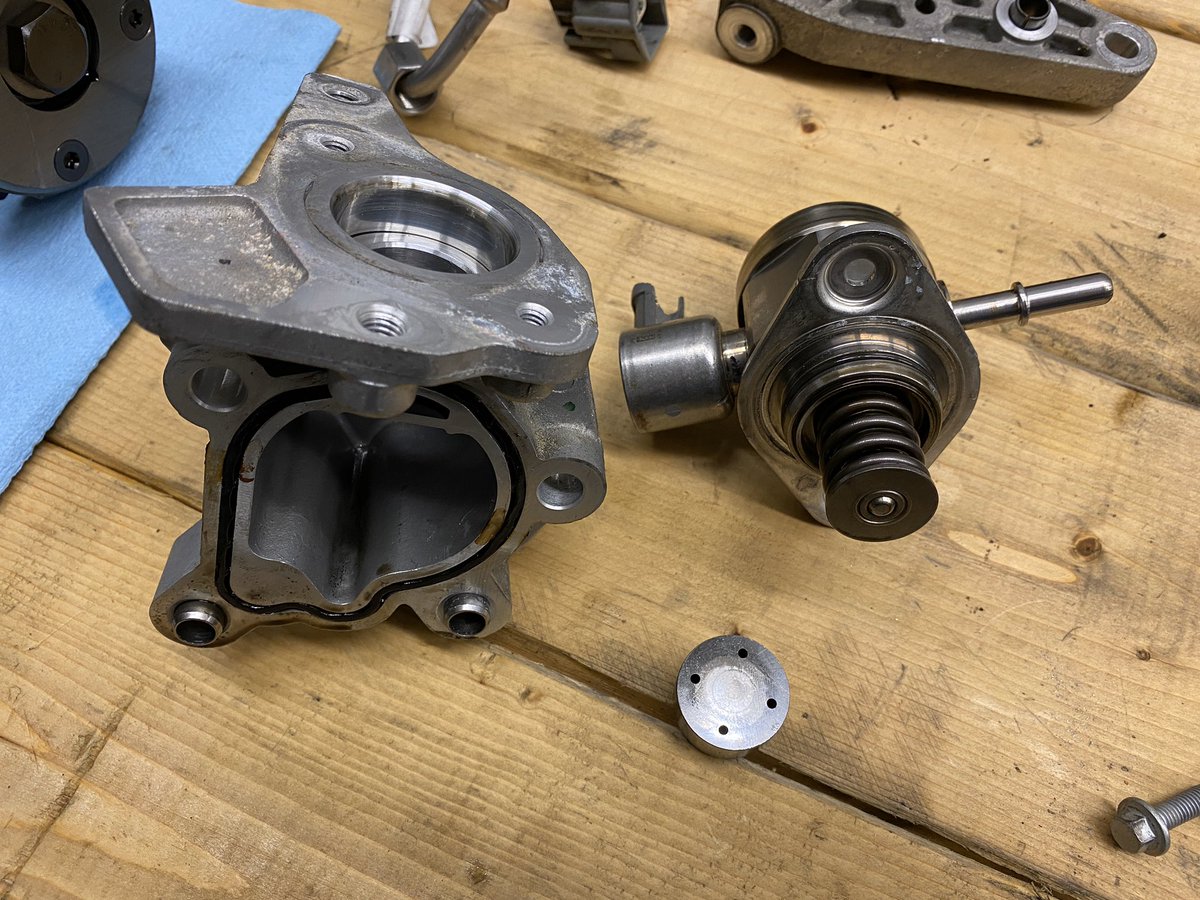

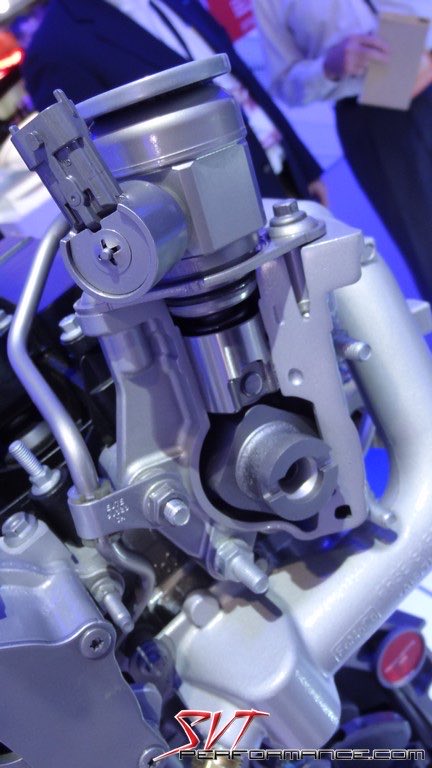

Cam caps removed. High pressure fuel pump is driven off the lobe of the exhaust cam visible in the top right corner.

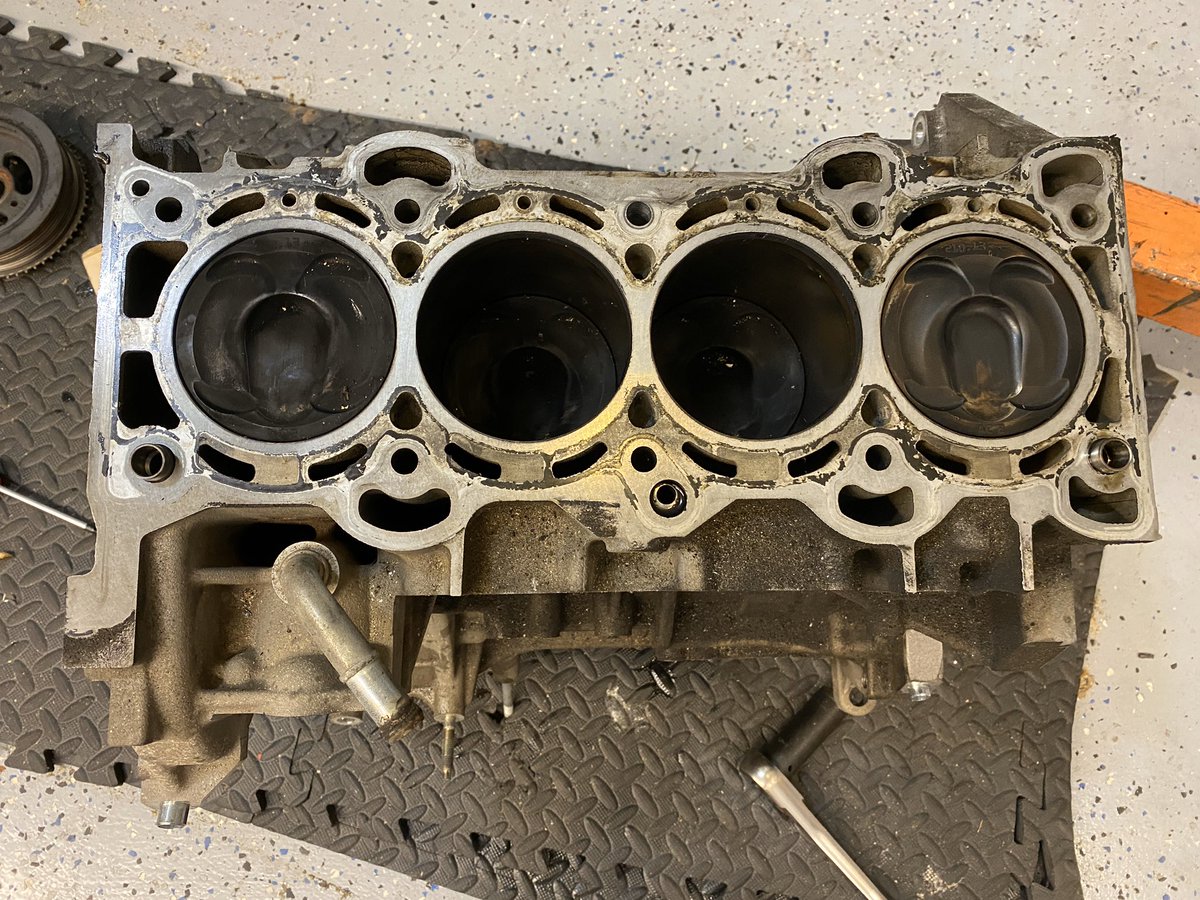

Now that we’re down to the block, it is visible that the piston on the right has been oil down. I took a rag to it before I took the photo.

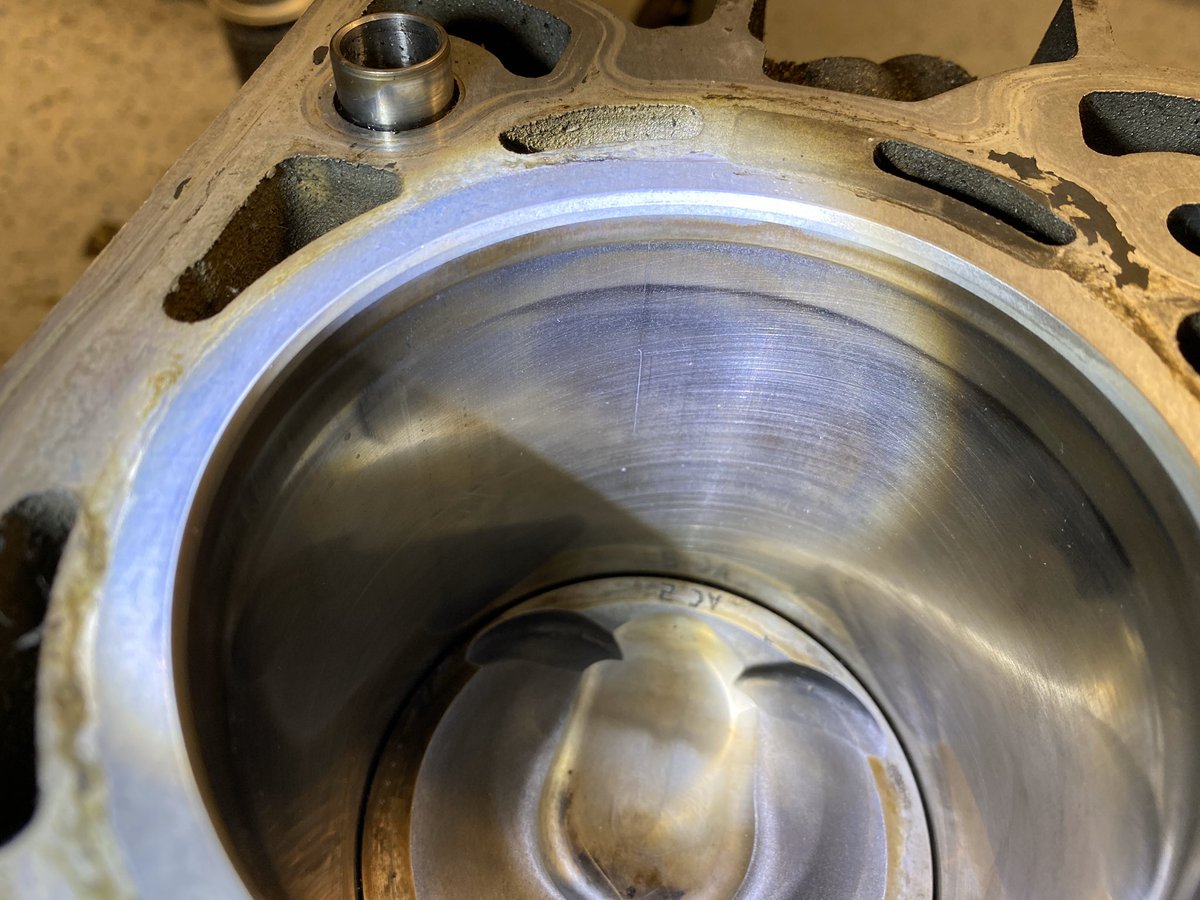

Cylinder walls look pretty good with cross hatching still visible. The suspect cylinder has a mark top to bottom in one location which we’ll investigate once we continue tearing it down further.

The fuel pump mechanism is kind of like a reverse valve setup with a tappet that pushes a stem which in turn pushes a piston inside to create fuel pressure. The electrical connector goes to a demand valve that controls fuel flow.

The Focus ST and Escape use the same type of flat tappet follower but the Focus RS gets an upgraded roller rocker type follower.

That& #39;s a good question. I believe the pump on the ST can go from 75 to 3,000 PSI and the averages I& #39;ve seen at WOT in the logs end up being around 2,300 PSI. https://twitter.com/notnotsteven/status/1253058956550746112?s=20">https://twitter.com/notnotste...

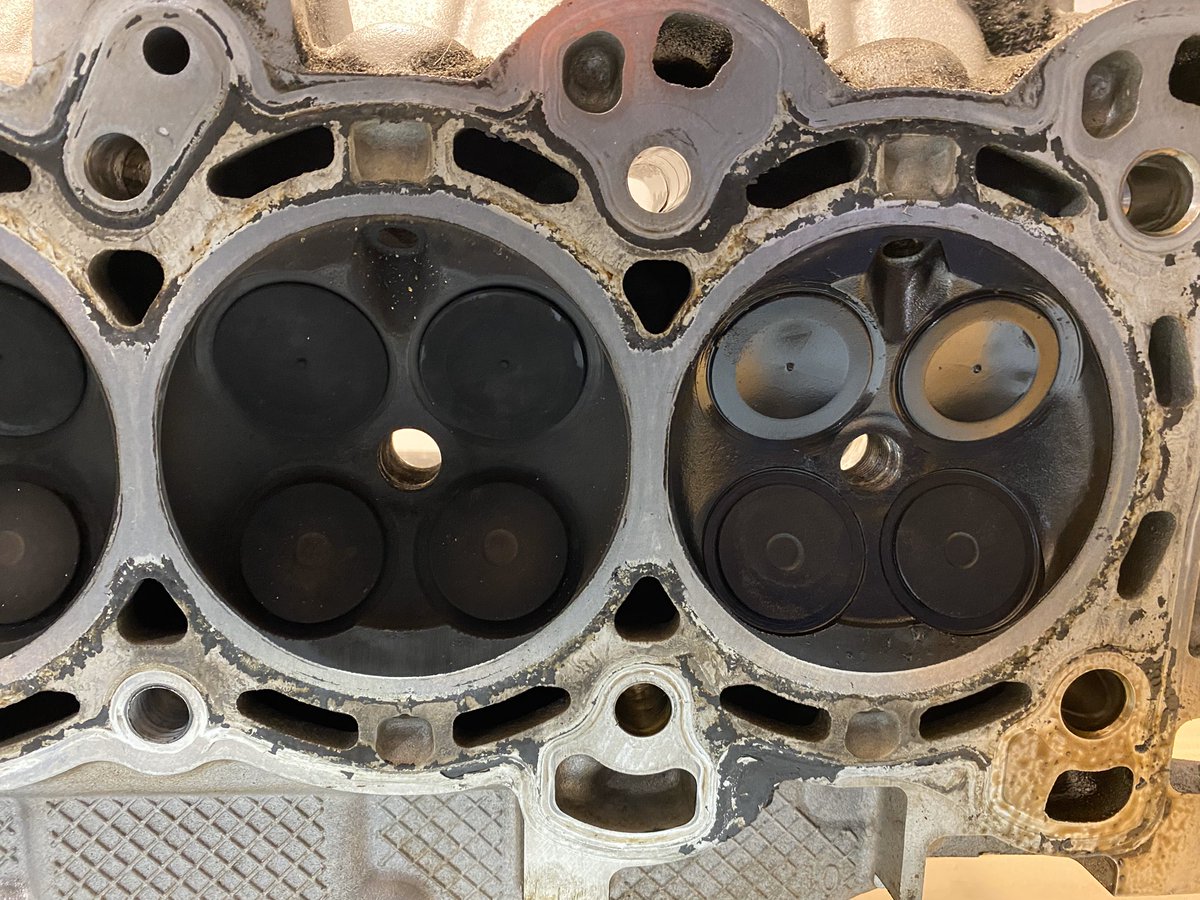

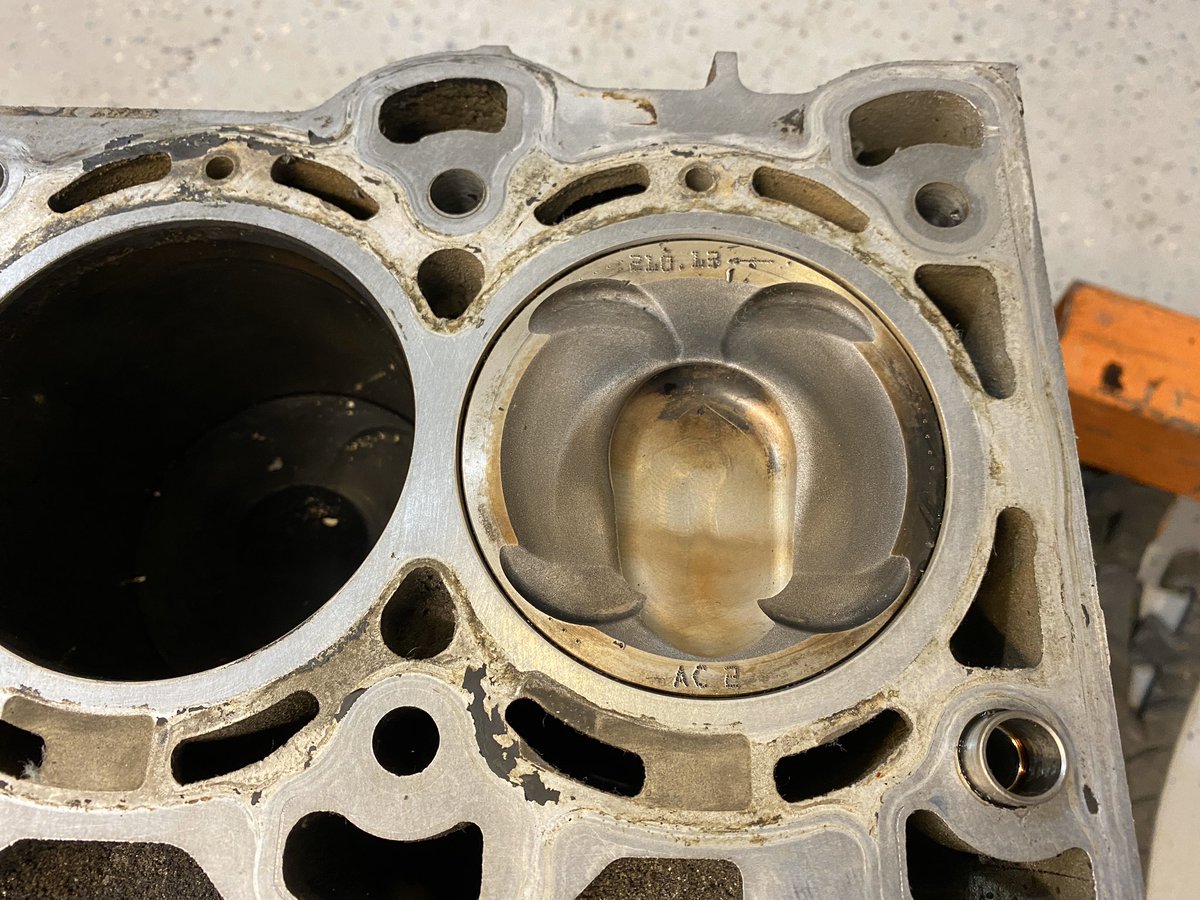

Found why the oil was getting past the piston. Part of the ringland was in the oil pan. Explains why the oil use suddenly accelerated after starting it that day along with the difference in compression.

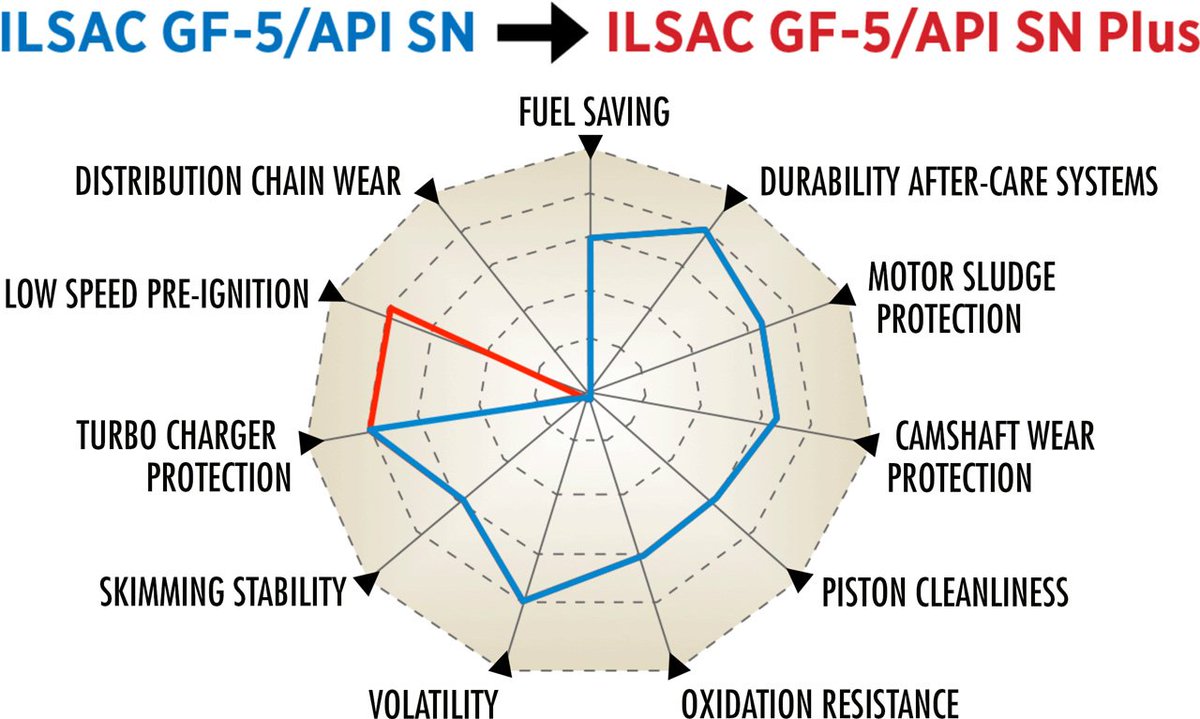

This damage was likely caused by low-speed pre-ignition (LSPI) which leads to superknock that happens with GDI engines and our modification of the engine possibly contributed to why it happened. http://stratifiedauto.com/blog/low-speed-pre-ignition-in-the-mazdaspeed-disi-and-ford-ecoboost-motors/">https://stratifiedauto.com/blog/low-...

It may look odd that the top of the piston looks pristine and the ringland failed below but it is not an uncommon failure mode on these engines. Another example from the forums.

Ouch. https://twitter.com/nassahG_/status/1253705984188518401?s=20">https://twitter.com/nassahG_/...

Modifying a car comes with inherent risks and if I& #39;m doing it then it is with the understanding that something I& #39;ve done may cause a failure and always approach it with that frame of mind and take responsibility for anything that happens.

I try to learn from failures but in this case there was absolutely nothing in the logs that showed any potential for failure as the fuel tables were a bit richer for safety and all of the knock counters were at zero so we started researching other potential causes.

Since this is a small turbocharged direct injected engine, LSPI seemed to be a reasonable potential cause and based on the trends with others with the same motor we think that& #39;s likely what happened in this case.

What we& #39;ve learned from this event is to make sure that we use "SN PLUS" category oil which is formulated to prevent LSPI in the replacement engine and to adjust shifting habits to make sure that low-speed high-load condition are reduced.

Read on Twitter

Read on Twitter