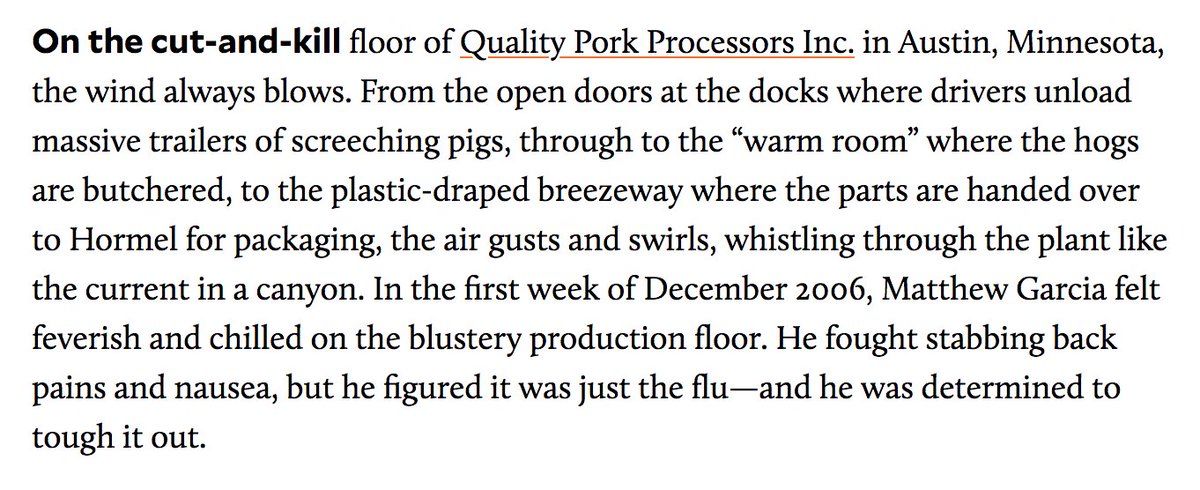

From 2008 to 2014, I worked on a book about an outbreak at a @HormelFoods pork processing plant in Austin, MN, and how it was tied to strain exerted on the supply chain by increased line speeds. Some people are asking my opinion on what& #39;s happening now. THREAD

I don& #39;t have an epidemiological knowledge of what is happening in meatpacking plants, but I do want to highlight one occupational factor to consider. And the case I worked on is relevant in one way: it was spread via exposure to aerosolized matter. https://www.motherjones.com/politics/2011/06/hormel-spam-pig-brains-disease/">https://www.motherjones.com/politics/...

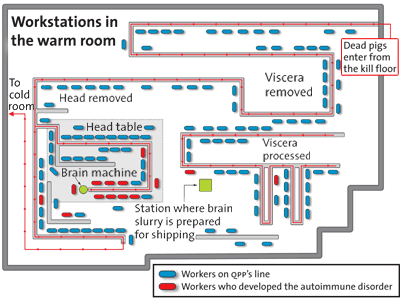

In that case, the disorder was brought on by inhaling aerosolize pig brain matter. But epidemiologists couldn& #39;t initially figure out why workers far removed from the "brain machine" were also falling ill.

The answer was wind. Many large meatpacking plants encompass both "hot side" (slaughter) and "cold side" (packing) operations. Refrigerating one side of the building and not the other creates constant winds.

Given what we know about how #COVID19 spreads, it seems highly likely that working in close quarters where the breath (and coughs) of co-workers are swirling constantly through the air would create an ideal environment for spread.

In the case that I studied, this problem was exacerbated by increasing line speeds. Faster lines meant that workers grew tired, less precise, and had less time to keep workspaces clean. The faster the lines ran, the greater the exposure (and risk) seemed to be.

Read on Twitter

Read on Twitter