I’m fed up of reading drivel about PPE so thought I’d do a thread with my two cents.

For information, I worked in the PPE for many years (admittedly over 15 years ago) today work with a number of importers of safety products getting their products online.

1?

For information, I worked in the PPE for many years (admittedly over 15 years ago) today work with a number of importers of safety products getting their products online.

1?

A bit of background - since the 60’s & 70’s PPE has been manufactured abroad. Initially this was done through Hong Kong but then moved to China after 1997.

The main manufacturing areas for disposable gloves is Malaysia & PPE generally, China.

2

The main manufacturing areas for disposable gloves is Malaysia & PPE generally, China.

2

Over time this accelerated so, at least when I was in the game, the only manufacturer of this kind of PPE left in the U.K. was JSP (famous for their hard hats) BUT even they imported the bulk of their masks from China.

Even back then in those days, all the good factories were massively over subscribed as the whole world moved to Far East manufacturing.

You’d be looking at 8 weeks - 4 weeks order lead time 4 weeks order shipment time by sea.

3

You’d be looking at 8 weeks - 4 weeks order lead time 4 weeks order shipment time by sea.

3

Even before this crisis broke out it had got worse - one company I’m working with now build in 4 months from order to receipt of goods.

However this year it got even worse. Why? There’s always a delay for Chinese New Year but this year it was exacerbated by the Chinese government extending the lock down after the New Year & a lot of production going internally.

Lead time in January was 6 months.

Lead time in January was 6 months.

No problem, switch to other countries. My guys tried to order from Pakistan.

Makes sense? No joy as the factories there are on lockdown, so you’re looking at july / August for orders placed in Jan / Feb.

India is exactly the same.

Makes sense? No joy as the factories there are on lockdown, so you’re looking at july / August for orders placed in Jan / Feb.

India is exactly the same.

It’s further delayed by countries turning the Chinese market into a free for all. People outbidding each other to secure manufacturing & the factories selling to the highest bidder.

Added to that countries are commandeering any of their internal production. So you’ve the US using the defence act to take 3M’s production, (and upsetting Germany as a result), and the French cancelling the UK’s order with one of their manufacturers.

With regards to Hancock’s statement about using PPE correctly I think he makes a valid point to remind people to use it correctly. Why? Because there’s a long history of massive waste in the public sector.

It always used to be well known in the industry that when it came to the end of the financial year for public sector bodies it was fill your boots time.

Why? Well if they didn’t spend their allocated budget that year it was reduced the next.

Why? Well if they didn’t spend their allocated budget that year it was reduced the next.

Why hasn’t the U.K. got a PPE manufacturing industry now? Simply Because these are low cost disposable items.

You want to manufacture masks in the U.K? Your price will be 3/5 times higher than the Chinese & before this you’d go out of business.

You want to manufacture masks in the U.K? Your price will be 3/5 times higher than the Chinese & before this you’d go out of business.

So what can we do going forward? Well the guys I work with are already talking about ‘near shoring’.

That is effeicvely moving to production nearer to Europe but low wage economies.

So you’re going to be seeing production move to Eastern Europe, Turkey & North Africa.

That is effeicvely moving to production nearer to Europe but low wage economies.

So you’re going to be seeing production move to Eastern Europe, Turkey & North Africa.

So against all this the bottom line is you simply cannot magic an imported product that all the word wants at the same time with massive over demand.

Nor can you force foreign companies to supply you becuase you’re the U.K.

We are fortunate in that we stockpiled for Brexit.

Nor can you force foreign companies to supply you becuase you’re the U.K.

We are fortunate in that we stockpiled for Brexit.

Sorry for breaking the order of the thread but some more thoughts as and when.

As a company you’ve managed to get your order from the factory but how do you get it here? Sea freigh is too long so you fly it in.

Except you can’t. Why?

As a company you’ve managed to get your order from the factory but how do you get it here? Sea freigh is too long so you fly it in.

Except you can’t. Why?

Well a lot of air freight traffic went through passenger planes the bas majority of which are now grounded. So there’s now under supply on airfreight capacity.

Fine if you’re a government but what about the swathes of care homes etc that buy from PPE companies?

Fine if you’re a government but what about the swathes of care homes etc that buy from PPE companies?

With regards to rubber gloves - heres Malaysia’s (and the worlds) biggest manufacturer Top Glove - who I worked with for a bit.

They cite labour shortages & given latex is a natural product I’m sure they’ll start seeing raw material shortages soon. https://www.fm-magazine.com/news/2020/mar/top-glove-malaysia-coronavirus-demand-23152.html">https://www.fm-magazine.com/news/2020...

They cite labour shortages & given latex is a natural product I’m sure they’ll start seeing raw material shortages soon. https://www.fm-magazine.com/news/2020/mar/top-glove-malaysia-coronavirus-demand-23152.html">https://www.fm-magazine.com/news/2020...

So, you can switch to synthetic rubber like nitrile, right?

Nope, nitrile still uses rubber from rubber trees as it’s base material. They are then reprocessed into nitrile compound.

I’m pretty certain there will but be enough rubber trees to meet demand in Malaysia.

Nope, nitrile still uses rubber from rubber trees as it’s base material. They are then reprocessed into nitrile compound.

I’m pretty certain there will but be enough rubber trees to meet demand in Malaysia.

Sorry meant to say:

There will not be enough rubber trees to meet demand.

There will not be enough rubber trees to meet demand.

Also, why are we in this situation being so reliant on overseas manufacturing for PPE?

Because huge buyers (like the NHS) have for decades put pressure to reduce costs on consumable items forcing suppliers to foreign manufacturers & destroying what U.K. industry there was.

Because huge buyers (like the NHS) have for decades put pressure to reduce costs on consumable items forcing suppliers to foreign manufacturers & destroying what U.K. industry there was.

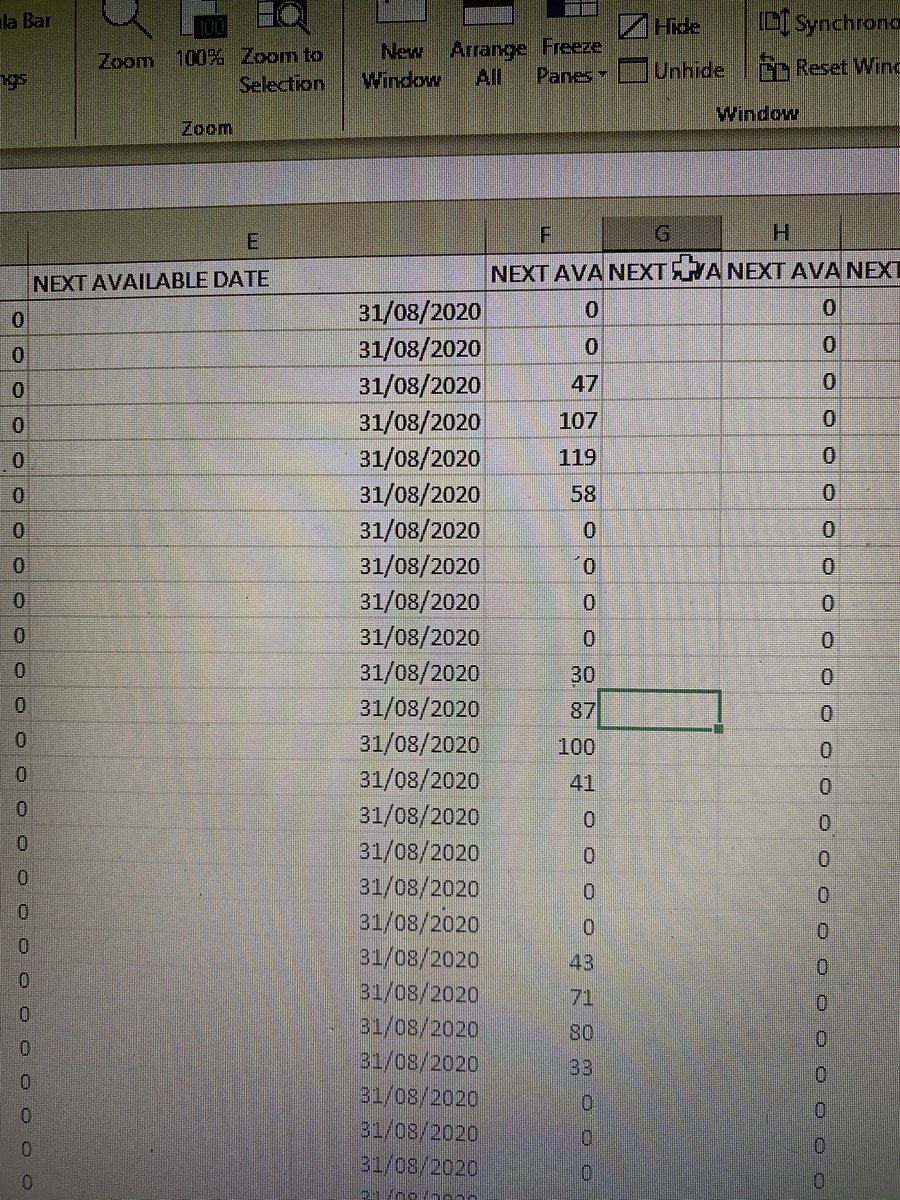

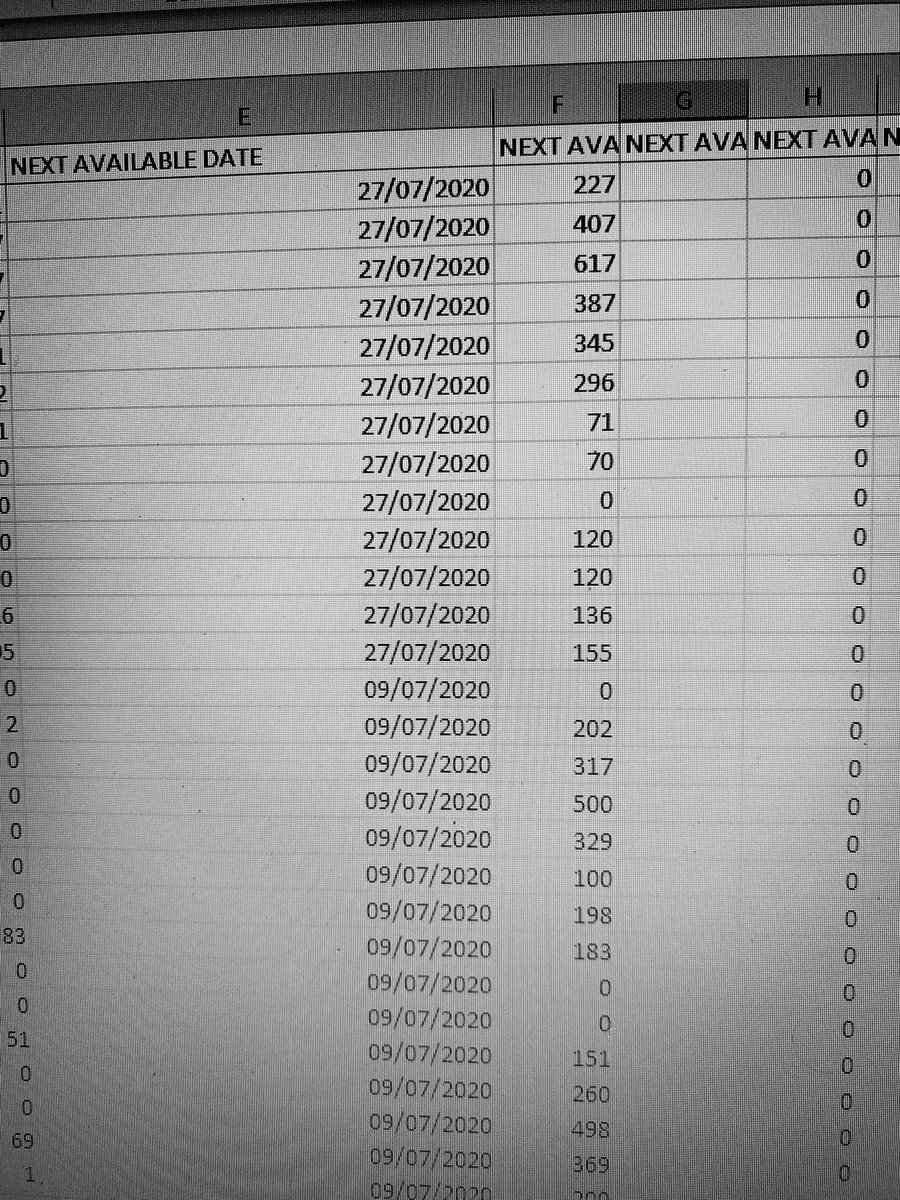

For all the dribbling goons here’s one of my clients import schedules. Most of these goods ordered Jan / Feb

And of course these are estimated delivery dates and will change.

My guys are expecting at least another 30 days delay over these items on many lines.

My guys are expecting at least another 30 days delay over these items on many lines.

I touched upon airfreight shortages - so let’s look at the more traditional (but linger) sea freight option.

No joy either there as there’s shortages of containers & ships are being held up in ports. https://www.google.co.uk/amp/s/www.bloomberg.com/amp/news/articles/2020-03-18/there-aren-t-enough-containers-to-keep-world-trade-flowing">https://www.google.co.uk/amp/s/www...

No joy either there as there’s shortages of containers & ships are being held up in ports. https://www.google.co.uk/amp/s/www.bloomberg.com/amp/news/articles/2020-03-18/there-aren-t-enough-containers-to-keep-world-trade-flowing">https://www.google.co.uk/amp/s/www...

One thing that hasn’t been mentioned about PPE, is the knock on effects on industry.

Traditionally PPE has been split into medical & industrial sectors.

If governments are buying all production for medical needs, how are other industries going to get supplies?

Traditionally PPE has been split into medical & industrial sectors.

If governments are buying all production for medical needs, how are other industries going to get supplies?

Many manufacturers cannot produce without the right PPE, it’s a production stopper.

Not so much an issue now due to lockdown, but when these factories re-open how can they produce if all PPE is going to medical sectors?

Not so much an issue now due to lockdown, but when these factories re-open how can they produce if all PPE is going to medical sectors?

For example, the car industry is a huge buyer of PPE.

What will happen to their production if they can’t get FFP3 masks for their paint shop as all the worlds production has been taken by health care?

What will happen to their production if they can’t get FFP3 masks for their paint shop as all the worlds production has been taken by health care?

So what’s happening I’ve been told is industry is also seeking to stockpile in order to protect its own operations driving demand up (lead times & prices) even more.

Which is why, one of my old sparring partners, ARCO, one of the largest PPE suppliers in the U.K, are putting out statements refusing to take on new customers & only supplying orders to the same value as pre crisis levels to existing customers to stop industry stockpiling.

And to further prove my point here’s a major U.K. PPE manufacturer,JSP, effectively refusing to supply masks to any industry other than medical.

There will be big knock on effects for other manufacturing industry moving forward.

There will be big knock on effects for other manufacturing industry moving forward.

Seeing that some (of the usual sorts) are questioning some of my posts, sou whilst I’ve dropped some sources in some of the tread. I’ll drop some more in.

Here’s an article about manufacturing issues in China after NY: https://www.google.co.uk/amp/s/www.nbcnews.com/news/amp/ncna1133966">https://www.google.co.uk/amp/s/www...

Here’s an article about manufacturing issues in China after NY: https://www.google.co.uk/amp/s/www.nbcnews.com/news/amp/ncna1133966">https://www.google.co.uk/amp/s/www...

Here’s a report about Pakistan factory shutdowns: https://sourcingjournal.com/topics/sourcing/pakistan-coronavirus-lockdown-garment-factories-closed-synergies-worldwide-levis-202444/">https://sourcingjournal.com/topics/so...

Here’s a bit more about the current free for all with Chinese PPE suppliers: https://www.google.co.uk/amp/s/m.economictimes.com/news/international/world-news/virus-battle-creates-a-global-quest-to-find-masks-and-ppe/amp_articleshow/74957043.cms">https://www.google.co.uk/amp/s/m.e...

Here’s 3m confirming that they’ve been hit with a DPA order:

https://news.3m.com/press-release/company-english/3m-response-defense-production-act-order

Also">https://news.3m.com/press-rel... here’s the French supplier saying the frenchbgovernment made them cancel their order to the NHS

https://www.google.co.uk/amp/s/www.euronews.com/amp/2020/03/06/coronavirus-french-protective-mask-manufacturer-scraps-nhs-order-to-keep-masks-in-france">https://www.google.co.uk/amp/s/www...

https://news.3m.com/press-release/company-english/3m-response-defense-production-act-order

Also">https://news.3m.com/press-rel... here’s the French supplier saying the frenchbgovernment made them cancel their order to the NHS

https://www.google.co.uk/amp/s/www.euronews.com/amp/2020/03/06/coronavirus-french-protective-mask-manufacturer-scraps-nhs-order-to-keep-masks-in-france">https://www.google.co.uk/amp/s/www...

Here’s more about air, sea & road freight issues:

https://www.google.co.uk/amp/s/mobile.reuters.com/article/amp/idUSKBN21A2PB

https://www.google.co.uk/amp/s/mob... href=" https://www.google.co.uk/amp/s/amp.ft.com/content/79a02264-6edc-11ea-89df-41bea055720b">https://www.google.co.uk/amp/s/amp...

https://www.google.co.uk/amp/s/mobile.reuters.com/article/amp/idUSKBN21A2PB

So, where I work I’ve got a PPE firm working next to me. They should be the busiest business in the world right now, right?

Wrong, they’re thinking of furloughing people. Why? Well it’s true they had a great few weeks & pretty much emptied their warehouse. Happy days!

Wrong, they’re thinking of furloughing people. Why? Well it’s true they had a great few weeks & pretty much emptied their warehouse. Happy days!

Their phone’s ringing off the hook, but guess what? They’ve got nothing to offer to their customers!

The get deliveries from some suppliers 1/2 times a week - supply it - then they’re all stood about waiting for the next delivery to arrive.

That’s the problem in microcosm.

The get deliveries from some suppliers 1/2 times a week - supply it - then they’re all stood about waiting for the next delivery to arrive.

That’s the problem in microcosm.

Read on Twitter

Read on Twitter