A short intro to front vs rear drive on tracked vehicles, off the back of some debates about front and rear engine layouts on future fighting vehicles. I& #39;m no expert, but hopefully lays out the basics for those interested. #miltwitter

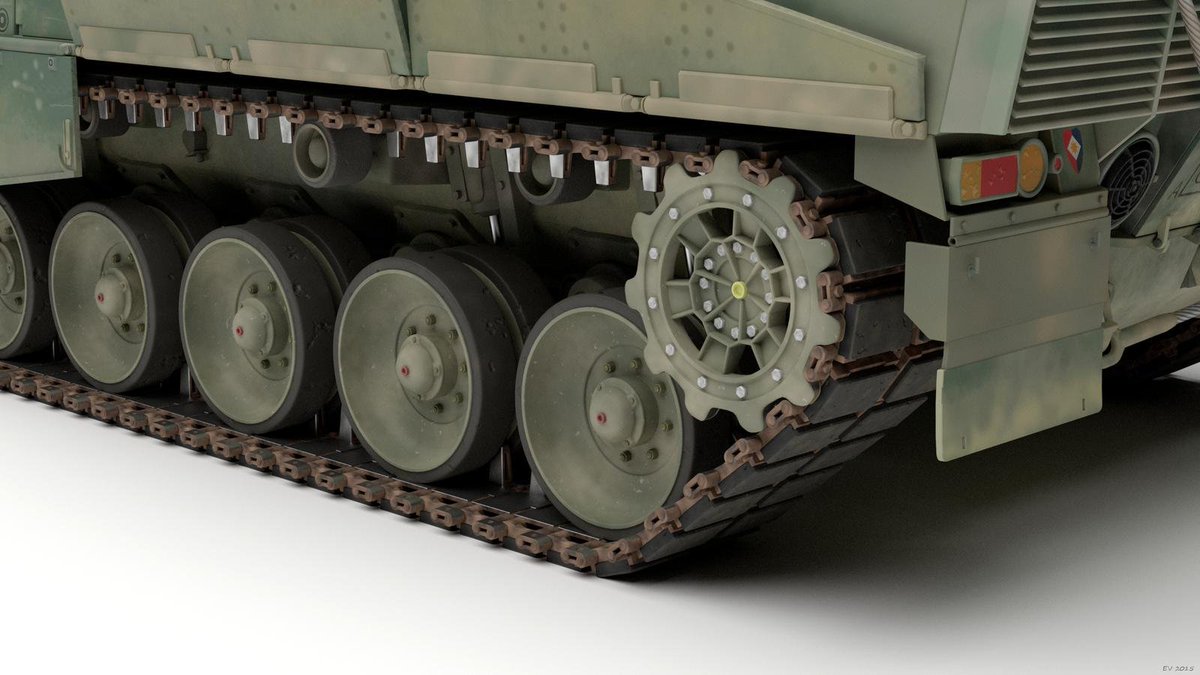

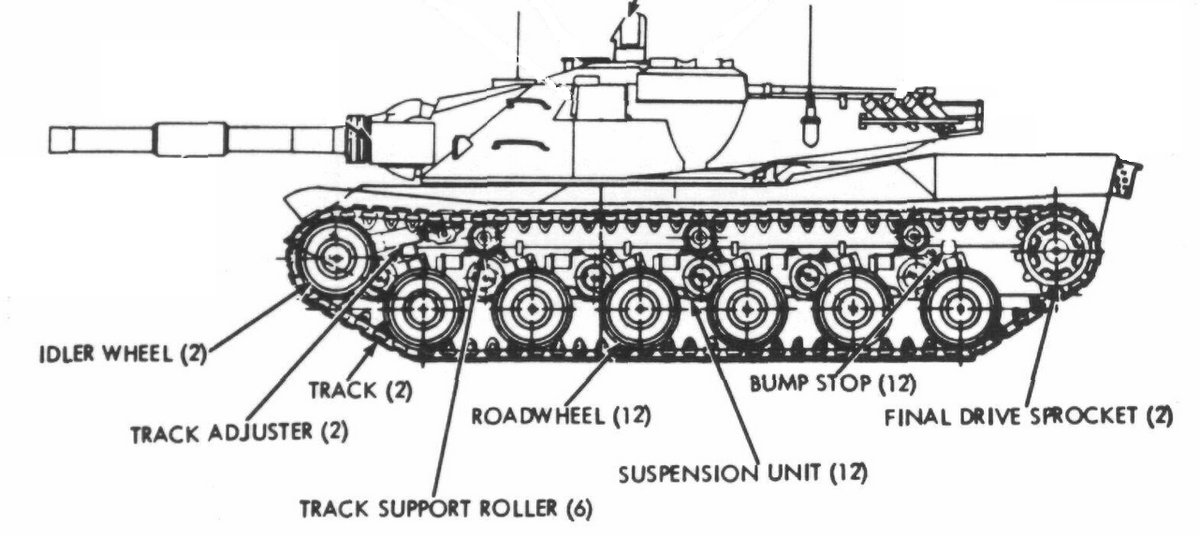

Tracked vehicles have a sprocket (geared wheel) and an idler (smooth wheel). The sprocket is transferring drive to the track via obvious mechanical means. You can have the sprocket at the front or the back, and in general tanks use rear, IFV and variants thereof use front.

Broadly engine location constrains drive location as you want the simplest, shortest and most space efficient means to connect transmission to sprocket. That said there have been vehicles with engines not co-located, incl. WW2 favourites Sherman, PzIV and Tiger, amongst others

Sprocket location affects track tension distribution. With front sprocket in forward motion track segments between sprocket & idler and between idler & rear roadwheel are subject to higher tension, whereas track segments between front roadwheel & sprocket are subject to lower

With rear sprocket only the track segments between rear sprocket & rear roadwheel are subject to higher tension, with track segments between front roadwheel & idler and those between idler & sprocket subject to lower tension.

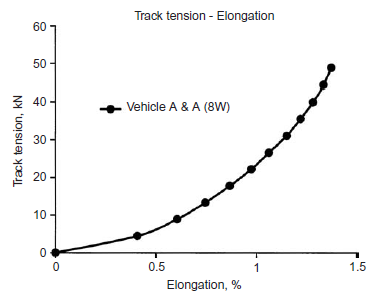

Steel track normally utilises rubber bushings which elongate when subject to tension. With front sprocket total elongation of track is larger than for a vehicle with rear sprocket. W/greater elongation more track can deflect and track segments become looser and support less load

This manifests in a few ways. Most overt is the higher likelihood of track skipping and consequent detracking of the vehicle, especially at high speed or low radii turns. In a military context this is potentially disastrous and thus keenly avoided where possible.

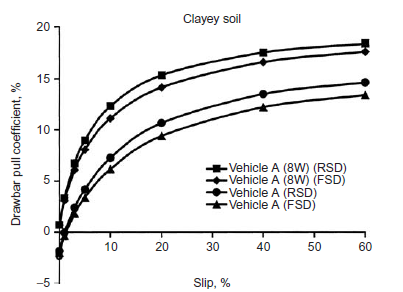

It also has a surprisingly big impact on mobility. Rear sprocket decreases mean maximum pressure, reducing track sinkage and resistance and thereby increasing tractive performance. Drawbar pull can be 8-14% better with rear vs front on normal clay-type soil terrain.

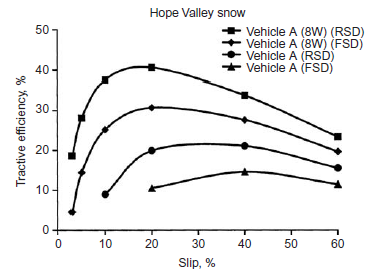

In snow or other soft terrain the effect is even greater, as the hull is bearing onto the surface too and so friction is a vastly more impactful factor. Drawbar pull in these circumstances can be 50-110% better with rear vs front.

# roadwheels have a big part to play but thats its own discussion, however more is generally better from this specific viewpoint (in the above charts Vehicle A has 5 roadhweels, Vehicle A (8w) has 8 and always has higher mobility in these models.

So rear is always better from tractive mobility perspective, and thats why essentially all tanks use this configuration. But as all things vehicle design, its about tradeoffs. Put engine at the rear of a vehicle carrying passengers and its a nightmare to get out. Mobility vs role

Compare here Bradley (front engine) with BMP-3 (rear engine). Getting out of BMP requires combination of rear and roof hatches to give clearance and climb over engine housing. Could be suggested to be an unacceptable tradeoff. Bradley meanwhile is a standard door and ramp affair

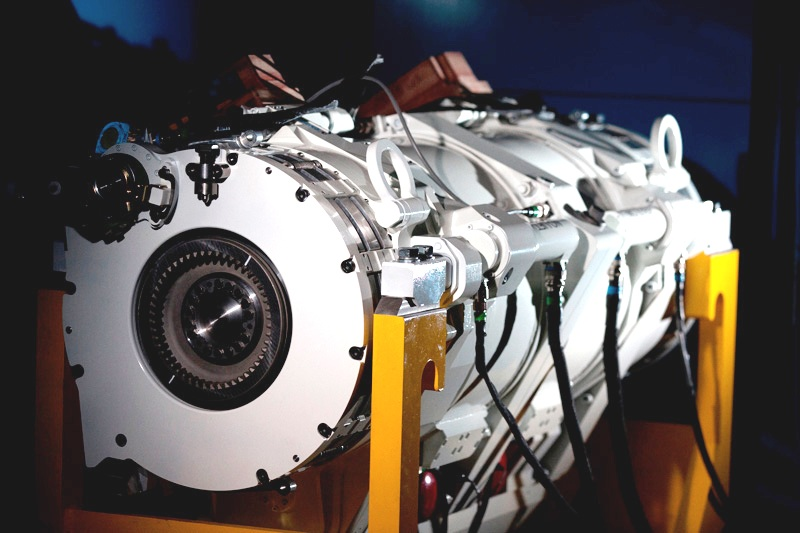

Electric drives offer potential flexibility with motors able to be located away from power generation and option of rear drive IFV possible. That said, only hybrid drive IFV to date, the GCV prototypes, had front drive because the drives ran the width of vehicle as a single unit

Read on Twitter

Read on Twitter