I am lucky... still have a job. To keep my mind calm from stress after-hours I will forge a sword from my old Datsun leaf-spring.

I used a hair dryer to amp up the heat to around 1300-1500 degrees then pounded the bend out on a railroad track I have.

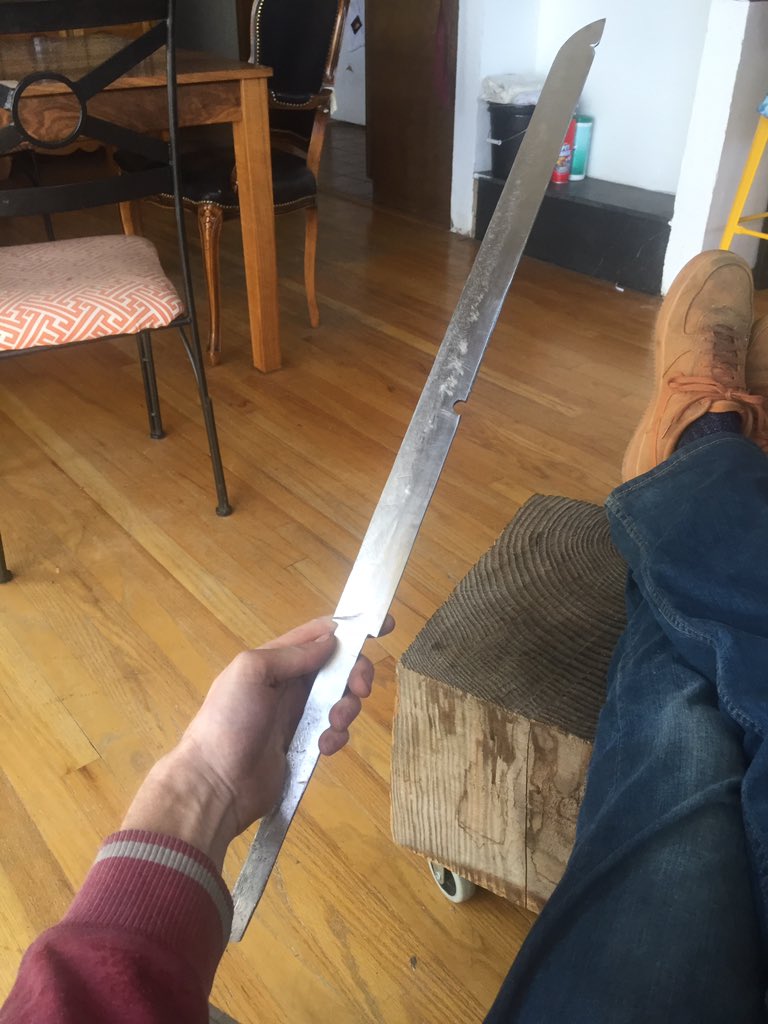

Once it& #39;s straight, I cut the basic shape with a diamond blade on my skill saw. Slow, and steady wins the game here. It& #39;s a reductive thing

My garage is packed full of two cars and 4 motorcycles right now because of covid my girlfriend demanded it. It& #39;s tight. But cozy.

Once it is cut and cleaned up the real work begins. The tang & length are the key to good balance. Get the sharp edge to 1/4 the total thick

I used drywall mud to insulate the spine and temper the blade. Fireplace this time. Denver has burn restrictions for outside.

Once the blade is tempered by quenching it in an oil bath after no magnet you put an edge on it with hand file and then water stone Work!!

Lots of elbow grease is used in the creation of a sword. Hand file is your best friend. Power sanders ruin the edge too quickly

Read on Twitter

Read on Twitter