I warned my Design for Manufacturing students that I, a professed injection molding fan girl, could EASILY devote an entire 2hr remote lecture to this revolutionary and ubiquitous process and then I accidentally...kinda...did  https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤷♀️" title="Woman shrugging" aria-label="Emoji: Woman shrugging">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤷♀️" title="Woman shrugging" aria-label="Emoji: Woman shrugging">

Ok so if there’s a consumer product near you right now that has a plastic component, it’s really likely that plastic component was injection molded. That lotion bottle? Injection blow molded. That top housing on that stapler? Injection molded. LEGO flower? Injection molded, babes

Injection Molding (IM) involves melting polymer pellets in a heated chamber that has a giant reciprocating screw in it. The screw makes the pellets tumble over each other, and that friction encourages the melt. The screw forces forward a shot of melted plastic into a mold.

So you’ve got melted plastic (the consistency of warm honey) being shot by the seat of its pants into a mold, and the plastic forces all the air out of the mold through teeny tiny air vents. This is critical—there’s a vacuum in the mold, it’s all plastic throughout, no air.

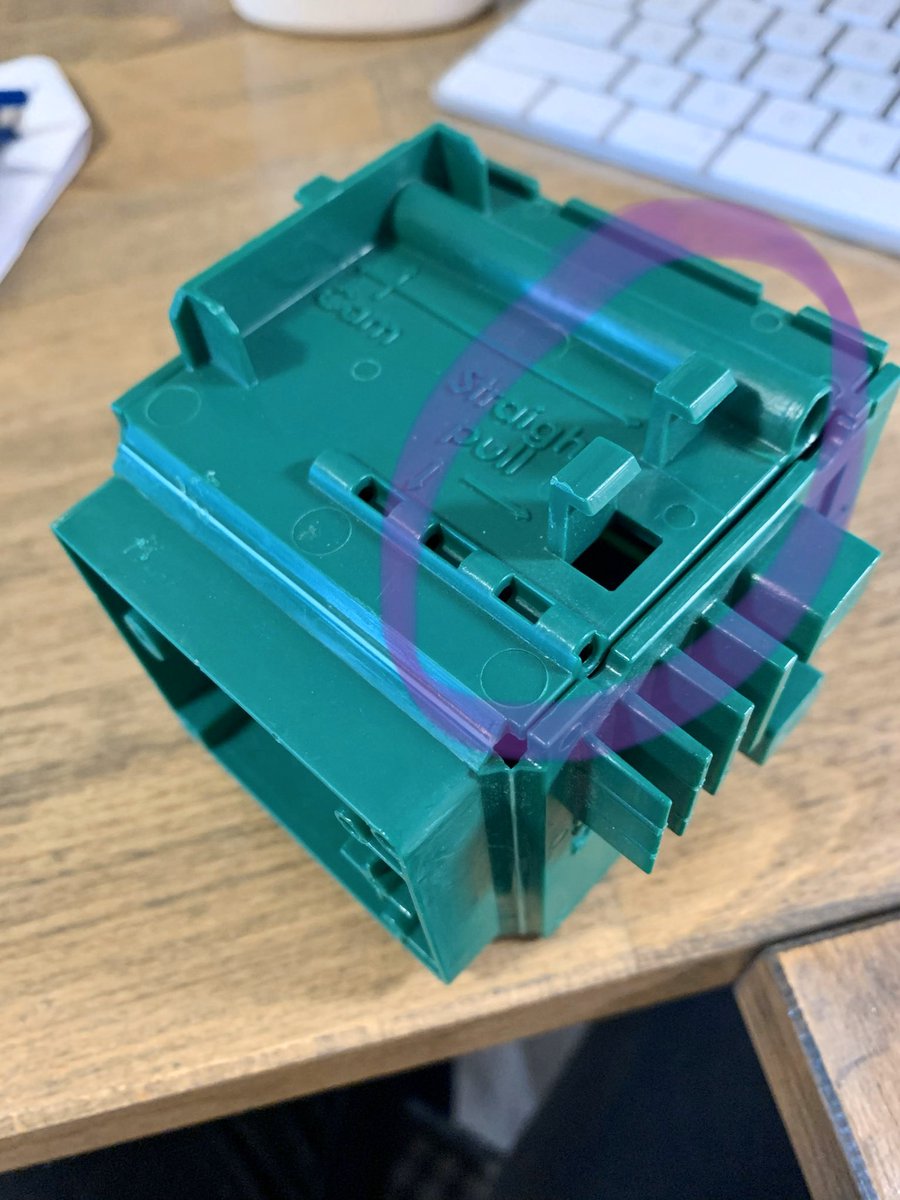

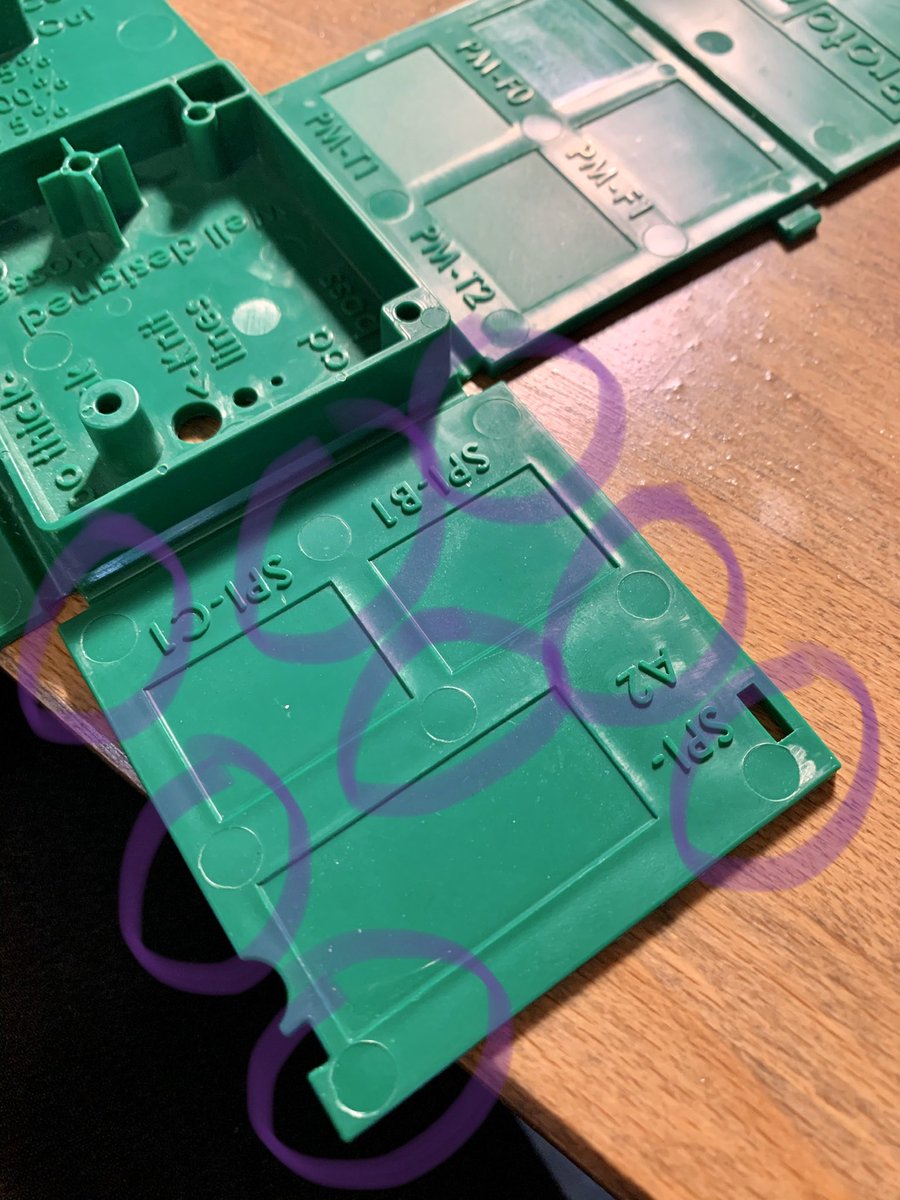

The molds are masterfully designed—you want the plastic to be injected at juuuust the right pressure and temperature to spread in the mold evenly and quickly. Most molds are two parts, but you can use in-mold action for undercuts so you can still get the halves of the mold apart.

Here’s the fun part: when the mold halves separate, the mostly cool part is popped out by ejector pins. These pins leave tiny circular indents in the part. These witness marks are everywhere!! Usually on the inside of parts so they don’t show. Go find some!

They’re like literally everywhere, friends. Even on the battery cover of my TI-83 Plus (love to my 80’s babies and our regulated high school calculators). Yes, I still use this thing all the time, and yes, it makes me feel fancy.

And sure, you could spend all your free time finding ejector pin marks, but also look for a parting line. That’s the where the two halves of the mold come apart. These are harder to find—most designers try to hide them if they can. Look at edges, like on my pink safety glasses.

IM works with most thermoplastics, can make super complex parts, is responsible for billions of LEGOs, and totally revolutionized what we can make out of plastics. Go forth with this moderately useful knowledge, my friends, and find some ejector pin marks!

Read on Twitter

Read on Twitter