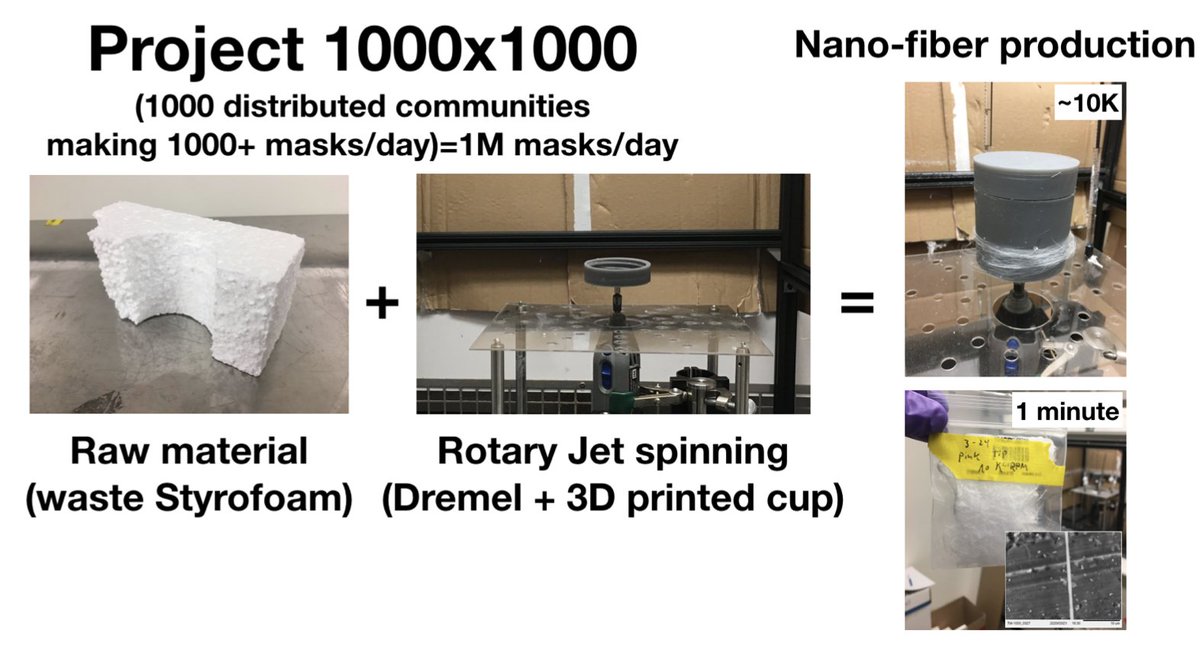

In COVID19 crisis, health care workers globally need upward of 80M+ N95 grade masks. N95 masks are fibrous nano-materials made via melt-blown; large scale factory can only make 1M mask/day. What if another solution existed to this problem - Introducing Project 1000x1000 (1/n)

Introducing Project 1000x1000: These are not normal times; we need new solutions. What if (big IF) 1000& #39;s of small businesses/fablab& #39;s could make specialized nano-materials for roughly 1000 to 10K N95 grade mask/day locally. 1000x1000 is a million mask/day produced locally. (2/n)

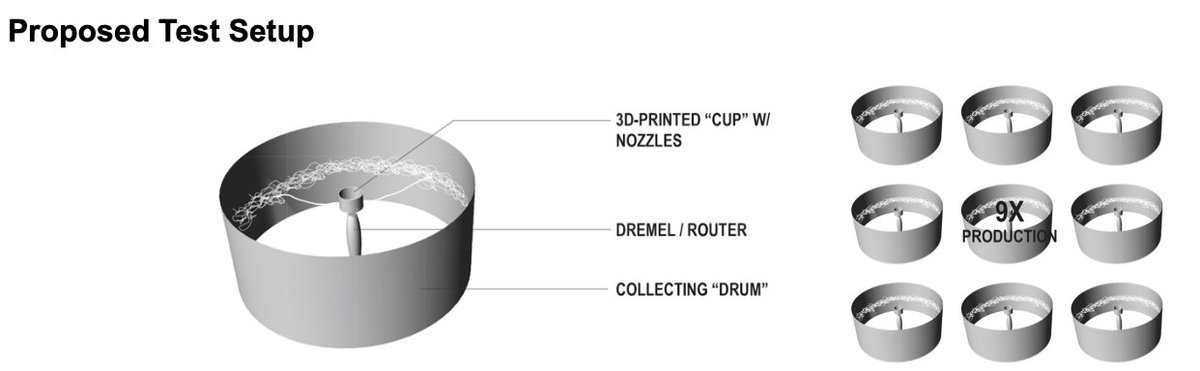

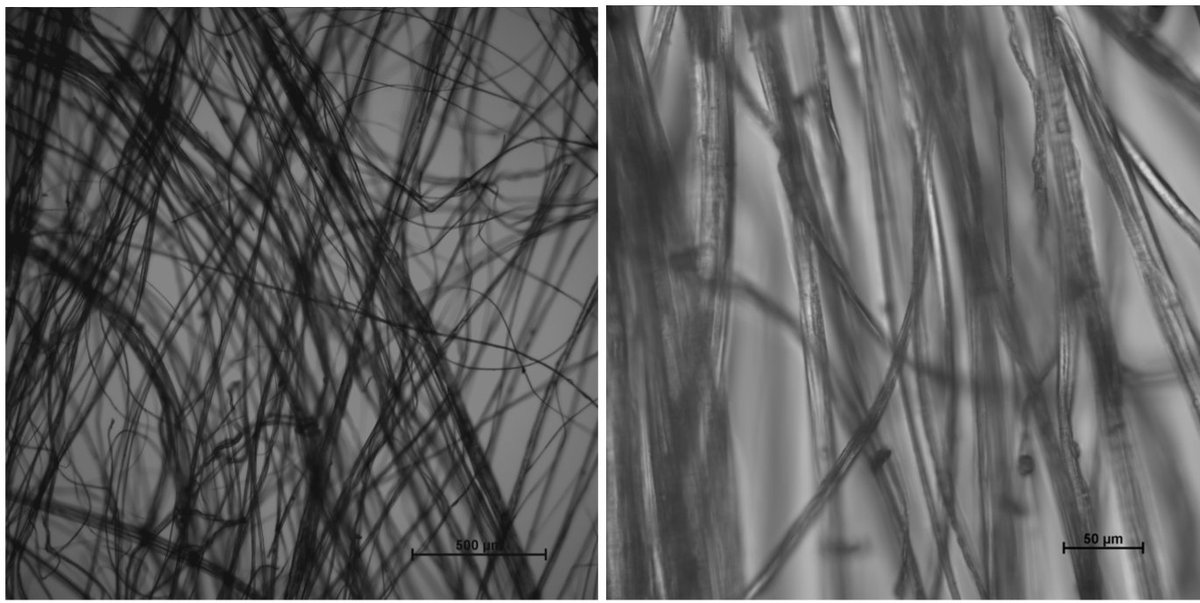

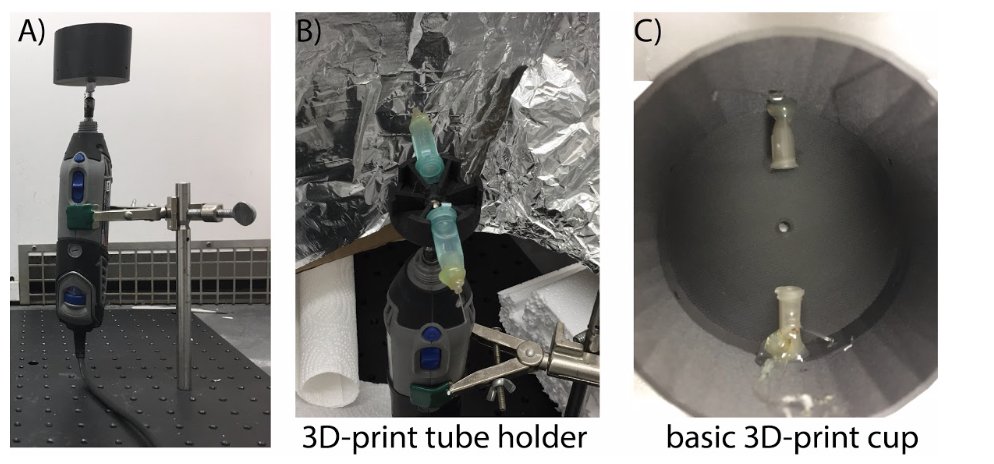

What if the only thing you needed was a few Dremel and a waste material: Styrofoam. This is an idea inspired by a cotton candy machine - if you take a polymer solution and spin it really fast (rotary jet spinning), you get a nano fiber mesh suitable to make filters.

Rotary jet spinning has been around for a long while, used for making incredible class of nano-materials and has a significantly higher throughput as compared to electro-spinning. We did the numbers - 10 Dremel spinning in parallel will make enough material for ~10,000 masks/day

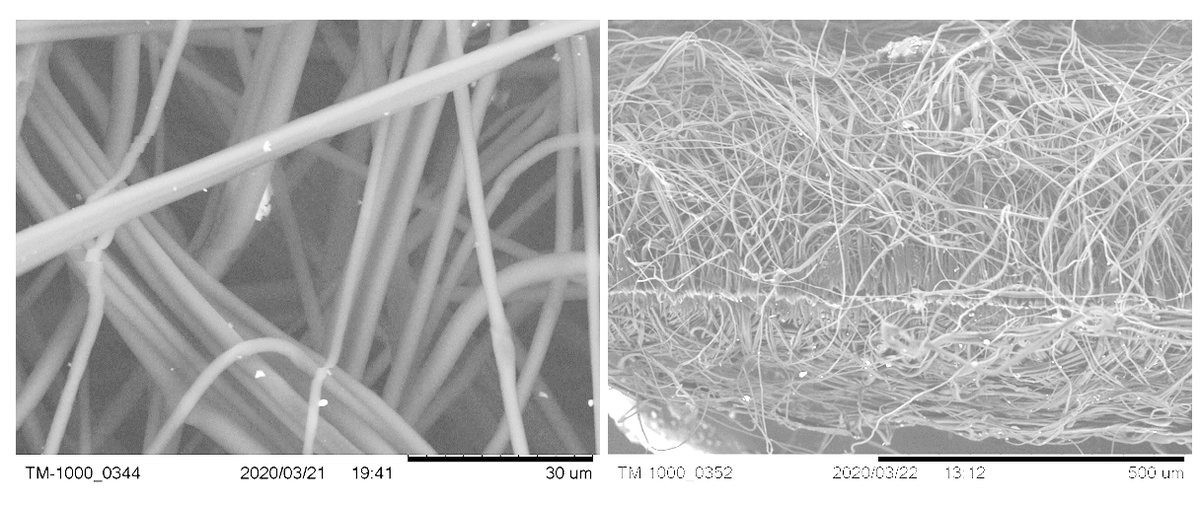

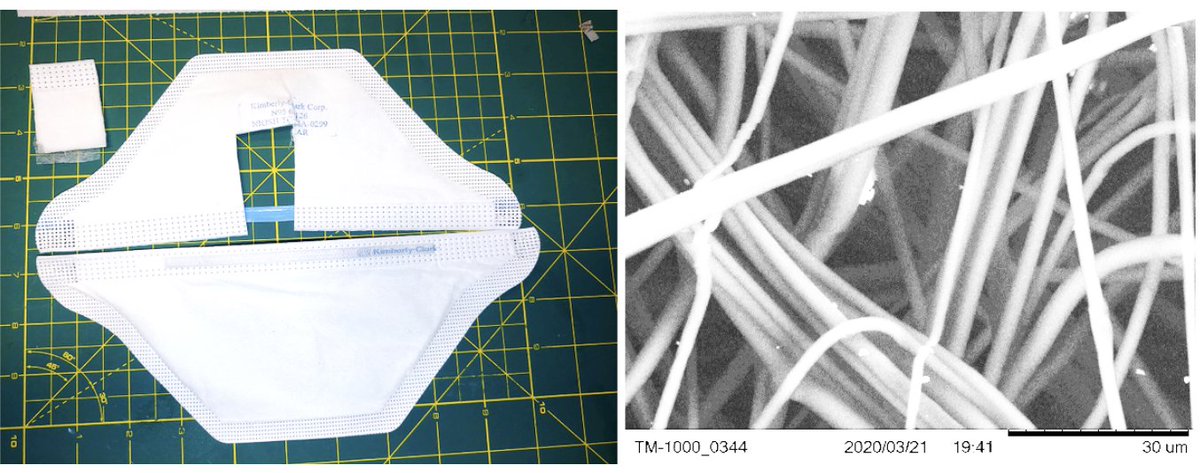

We are in early phase of testing this idea - so we don& #39;t know if it& #39;s possible. But it was a joyful moment to see the first fibers - specially when made out of a material that is considered a waste product. (5/n)

It is a joy to watch the setup churn fibers. Now its important to note - we have just made nano-fibers - long way to go to actually make filters that could meet the N95 standards. But we are sharing early so others could try these ideas or come up with better ideas. (6/n)

To replicate our setup - all you need is a Dremel and some 3D printed parts. We are hoping that small business and professionals in manufacturing can start exploring this process. For this to work, we still need stringent quality control & performance measurement & testing (7/n)

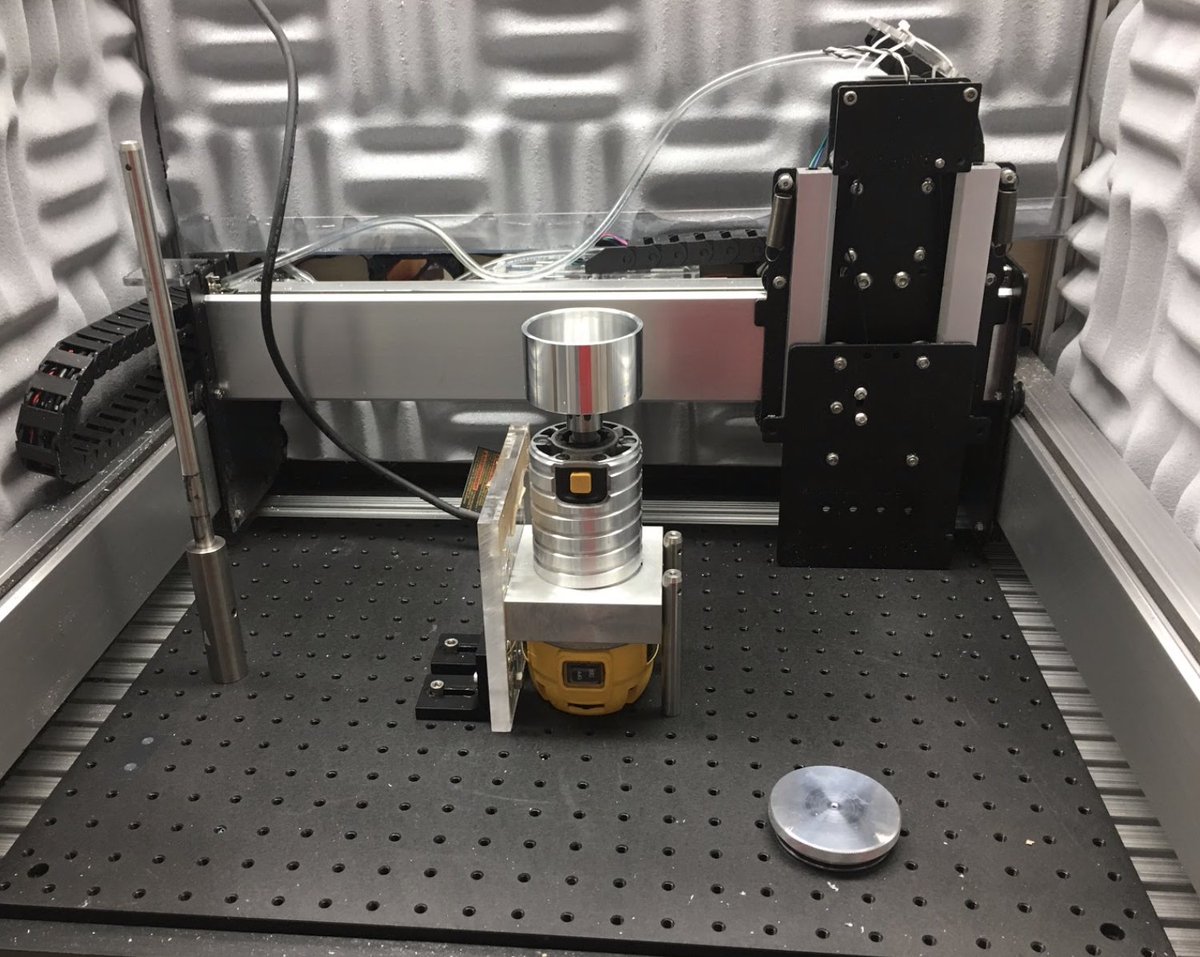

But thankfully, handheld particle counters used to test mask performance are easy to obtain and could be widely used for testing performance (of all kind of masks). We just set one up to test performance for our materials but also decontamination protocols for N95 masks (8/n)

With all the IFs and BUTs - we are approaching this very carefully (I can see a million reasons it might not work) but we have to try. We are looking for people to help us, join forces & replicate - all protocols and details documented LIVE here (9/n) https://docs.google.com/document/d/1aACcbkyZjR7nZy_wWeGQ9U2iGy0y4QajBeOL8RqAZIQ/edit#">https://docs.google.com/document/...

After this crisis is over - I want to imagine a new world where we question how things are currently made and explore should we build local capacity of small businesses to make technologically sophisticated products. But right now, we put our head down and try to help (10/n)

Project 1000x1000 is led by Anton Molina, Pranav Vyas, Shailabh Kumar and Anesta Kothari in the lab - with tremendous help from others. It& #39;s been amazing to see how we can go from an idea to something in hand in the time of crisis. (11/n)

And with 1000& #39;s of communities gearing up to help - who knows what is possible. Just want to make it clear - we do not have a working filter material yet; we are making progress which is what I am sharing here. Progress not equal to success (12/n) https://docs.google.com/document/d/1aACcbkyZjR7nZy_wWeGQ9U2iGy0y4QajBeOL8RqAZIQ/">https://docs.google.com/document/... (12/n)

Read on Twitter

Read on Twitter