This week& #39;s totally nothing to do with defence thread is about fixing and anchors, no, not the nautical anchor, but the type used to secure things to walls

1/

1/

Before I start, the usual disclaimer that you should always consult a professional, do your own research and follow the manufacturer& #39;s guidelines on any of this stuff, without sounding too alarmist, use the wrong method and you could have a serious problem

/2

/2

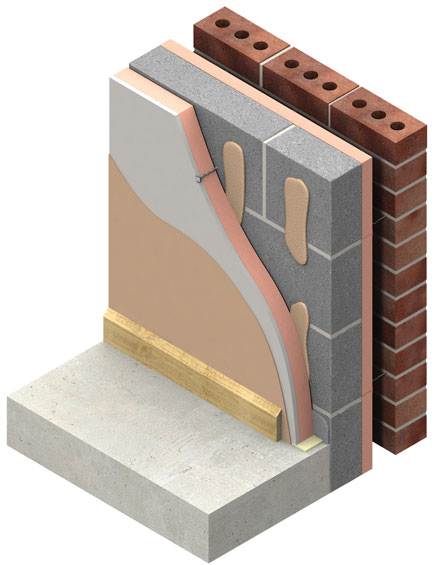

The single most important thing is to know the surface you are fixing into; concrete, brick, block, timber, cavity walls, dot and dab etc.

3/

3/

After this, everything should be logical; match the weight of the object being fixed to the wall with the correct type of fixing for the type of wall and FOLLOW THE INSTRUCTIONS

/4

/4

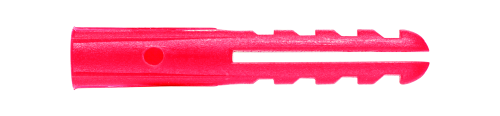

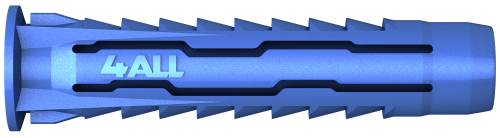

For brick/masonry, concrete and concrete block, the easiest to use is the expanding plastic plug, known by most as the rawlplug and probably the most widespread in use. There are many types, often colour coded depending on size, from lots of manufacturers

/5

/5

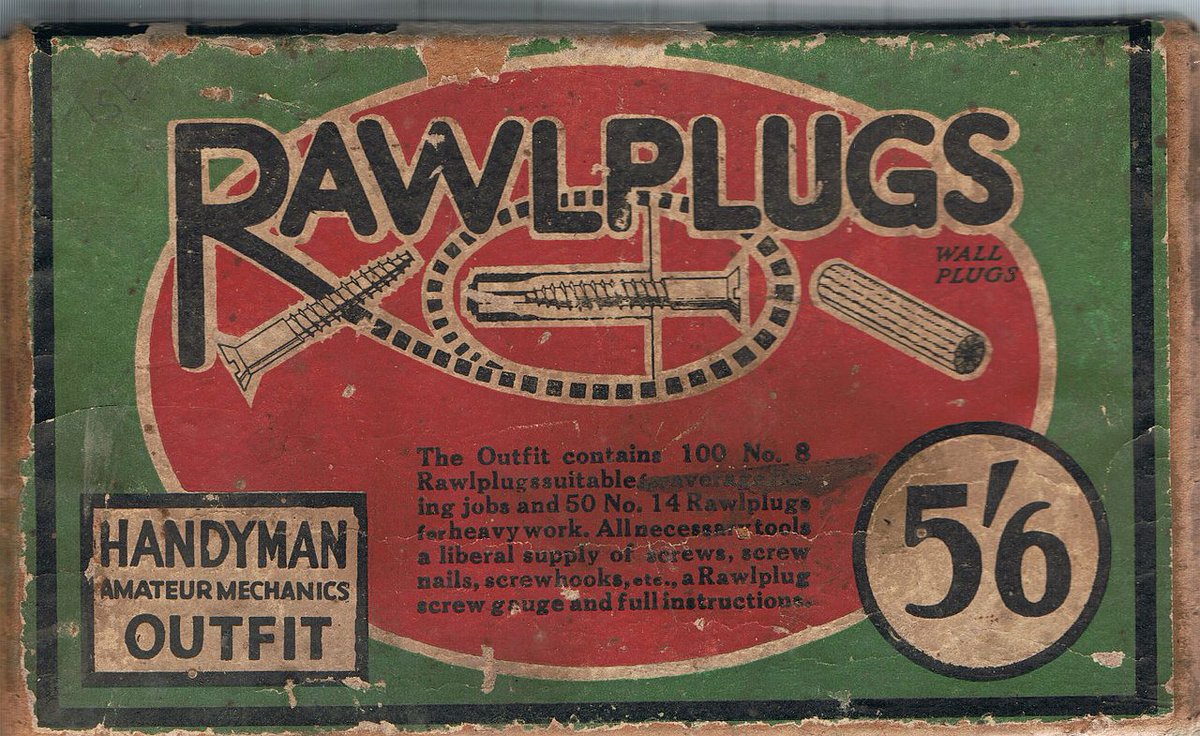

Plastic wall plugs or anchors were predated by timber blocks that would be hammered into masonry but the well-known Rawlplug was invented by John Joseph Rawlings, a British inventor, in 1910. His company was contracted to refit electrical wiring in the British Museum

/6

/6

As the screw is driven in, the plug expands into the predrilled hole and creates a mechanical bond. The brand was registered in 1912 and the rest is history. Read more at the link below

/7

#42">https://www.rawlplug.com/en/sustainable/rawlplug-brand/our-story #42">https://www.rawlplug.com/en/sustai...

/7

#42">https://www.rawlplug.com/en/sustainable/rawlplug-brand/our-story #42">https://www.rawlplug.com/en/sustai...

Usually, yellow plugs require a 5mm hole, red 6mm and brown, 7mm. If you are using an SDS drill these tend to create an oversize hole so be careful to match the actual hole size to plug.

/8

/8

For the majority of domestic lightweight non specialised tasks, these are perfectly acceptable, but you have to have a good wall to work with

/9

/9

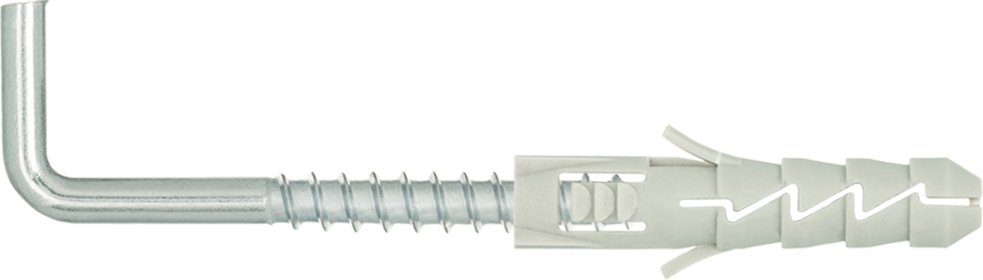

Expanding plastic plugs have evolved, frame and hammer in fixings, universal plugs that can be used with hollow bricks or cavity walls for example. Some also come with integral bolts, hooks and eyebolts.

/10

/10

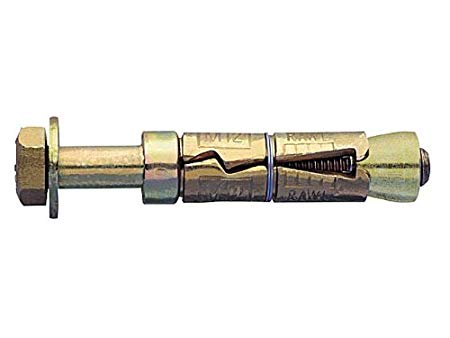

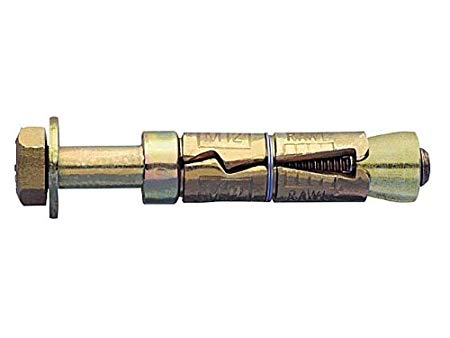

These are all relatively lightweight, and generally not fire resistant. So if you have something heavy to hang or need a more robust anchor for use in harsher environments, the expanding shield anchor is preferred.

/12

/12

Again, we can look at the Rawlplug Company, the first mechanical anchor created by them in 1930, called the Rawbolt

/13

/13

There are many variations; different materials, integral fixings, highly specialised for hanging cable tray from concrete floors, with different torque requirements and corrosion resistance. Considerations include substrate, environment, spacing and performance

/14

/14

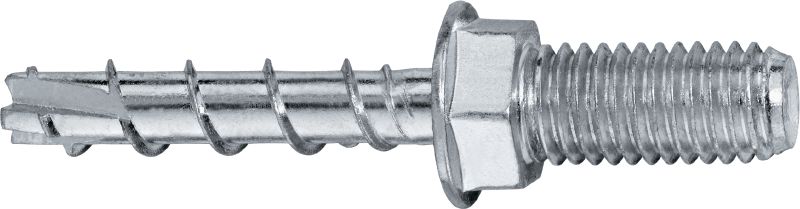

A more recent innovation is the use of concrete screws, these utilise their hardness to act as the name implies, a screw for concrete, and are available with hex or countersunk heads

/15

/15

Chemical, or bonded, anchors use polyester resins and a hardener to create a chemical bond between substrate and anchor. They can be used with threaded rod, rebar and sockets.

/16

/16

They are often used in poor conditions, where the substrate is cracked or where high degree of corrosion or chemical resistance is required

/17 https://www.youtube.com/watch?v=Dq8xM2UVA3M">https://www.youtube.com/watch...

/17 https://www.youtube.com/watch?v=Dq8xM2UVA3M">https://www.youtube.com/watch...

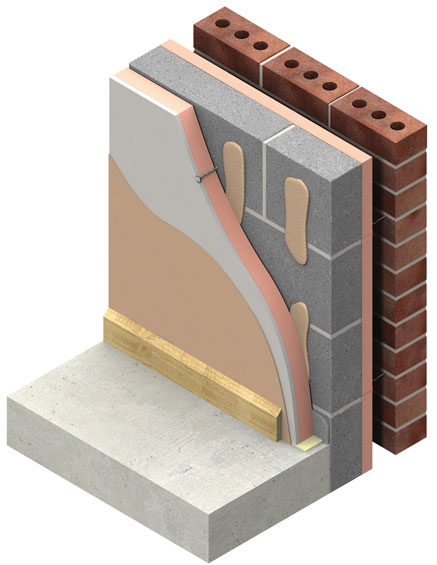

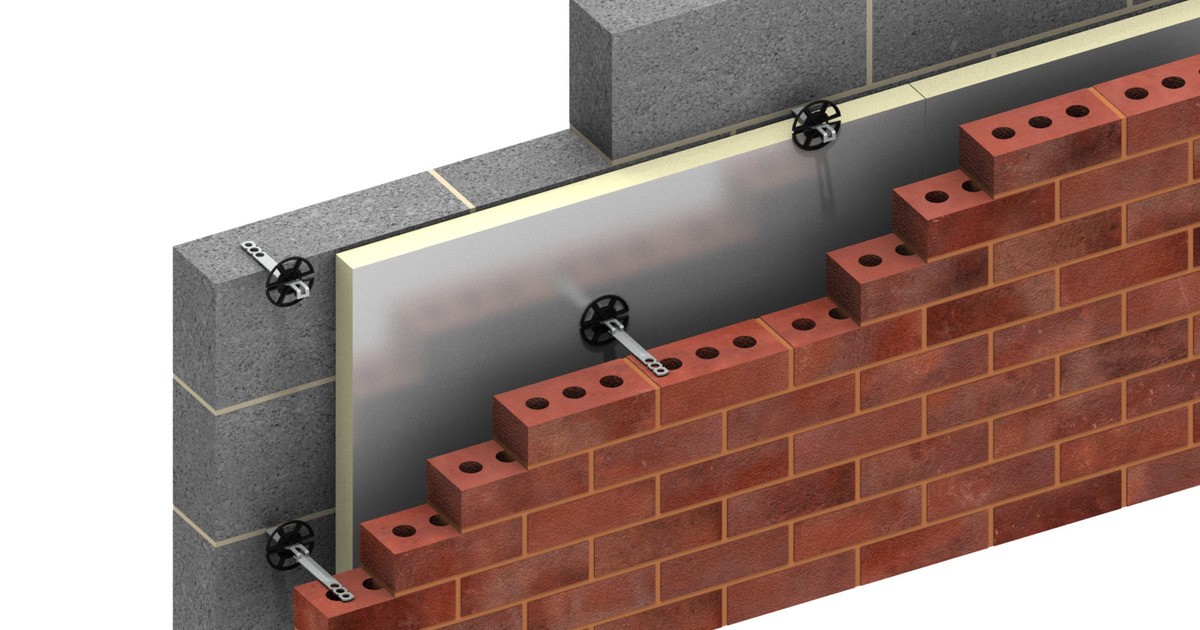

All the above are for concrete, stone or masonry, generally a single surface. Things get a bit more complicated where the wall has multiple elements, dot and dab plasterboard, or plasterboard partition walls.

/18

/18

Hybrid wall plugs use the screw to expand part of the body behind the plasterboard, they can also be used for hollow bricks

/19 https://www.youtube.com/watch?v=uyO2pJhitFU&feature=emb_title">https://www.youtube.com/watch...

/19 https://www.youtube.com/watch?v=uyO2pJhitFU&feature=emb_title">https://www.youtube.com/watch...

Hammer or in or screw in plasterboard fixings usually require specific screws but if metal, are fire resistant and easy to install. Not a fan of these myself to be honest but if you are in a bind, better than nothing

/20

/20

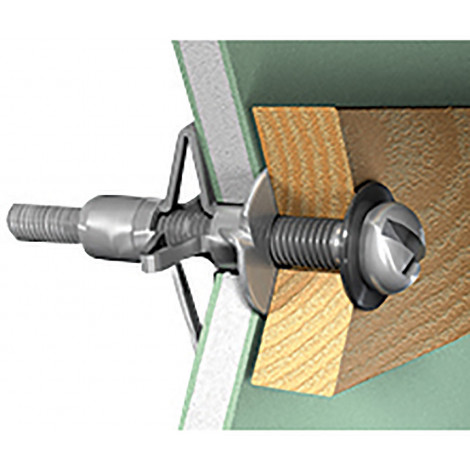

For a more robust fixing, interset or toggle fixings can be used with plasterboard walls, bot work by gripping the rear surface of the plaster inside the cavity. Both of these are excellent

/21

/21

More recent innovations include the Gripit

/22 https://www.youtube.com/watch?time_continue=1&v=tFYuUut_tAg">https://www.youtube.com/watch...

/22 https://www.youtube.com/watch?time_continue=1&v=tFYuUut_tAg">https://www.youtube.com/watch...

And the Bladefixer, this being particularly robust

/23 https://www.youtube.com/watch?v=BWzbLB3YD2g">https://www.youtube.com/watch...

/23 https://www.youtube.com/watch?v=BWzbLB3YD2g">https://www.youtube.com/watch...

No matter what the surface or load application, or in whatever environmental conditions, there are lots of options, other than nails!. If you can, locate a joist or string part of the wall in question, if not, identify the wall type and look at the guidelines

/24

/24

And to finish, this is a masonry drill bit, HSS drill bit and SDS drill bit, they are not the same

Maybe another thread :)

/END

Maybe another thread :)

/END

PS, forgot these, if you have an already drilled hole that looks like a wizards cuff (not all will get that joke), these can be a great & #39;get out of jail free& #39; option, although don& #39;t be hanging anything too heavy https://www.youtube.com/watch?v=UqAabliaOrA">https://www.youtube.com/watch...

Read on Twitter

Read on Twitter