Since am too lazay even to watch something (Strike Back!  https://abs.twimg.com/emoji/v2/... draggable="false" alt="😎" title="Lächelndes Gesicht mit Sonnenbrille" aria-label="Emoji: Lächelndes Gesicht mit Sonnenbrille">), Naona tuanze lesson yetu ya Solar. We will probably be doing this in the evenings coz of too much commitments during the day...

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😎" title="Lächelndes Gesicht mit Sonnenbrille" aria-label="Emoji: Lächelndes Gesicht mit Sonnenbrille">), Naona tuanze lesson yetu ya Solar. We will probably be doing this in the evenings coz of too much commitments during the day...

I will try be serious over this period, and not retweet stupid things I see online.  https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

Anyways, why solar? There are so many reasons as to why people install solar. Common reasons(in no particular order);

1. Preserve the environment (going green)

2. Reduce on power bills

3. Generation of own power where grid doesn& #39;t exist

4. Financial ability! https://abs.twimg.com/emoji/v2/... draggable="false" alt="😉" title="Zwinkerndes Gesicht" aria-label="Emoji: Zwinkerndes Gesicht">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😉" title="Zwinkerndes Gesicht" aria-label="Emoji: Zwinkerndes Gesicht">

1. Preserve the environment (going green)

2. Reduce on power bills

3. Generation of own power where grid doesn& #39;t exist

4. Financial ability!

One thing you need to know is It& #39;s both cheap and expensive (depending on how you look at it. It& #39;s capital intensive, with a longer d ROI period). In most cases for domestic usage, Kenya power is still a cheaper option especially in urban areas as it& #39;s stable na readily available

So what happens? Basically, it& #39;s conversion of Sunlight to electricity through various forms on harnessing the sun energy. For us, Photovoltaics(PV) is where our focus will be

A Photovoltaic(PV) cell is a solar cell essentially made from Silicon material (too much detail, too much physics, too boring really) but that Ka blue colour you see in panels is a sign that silicon is present.

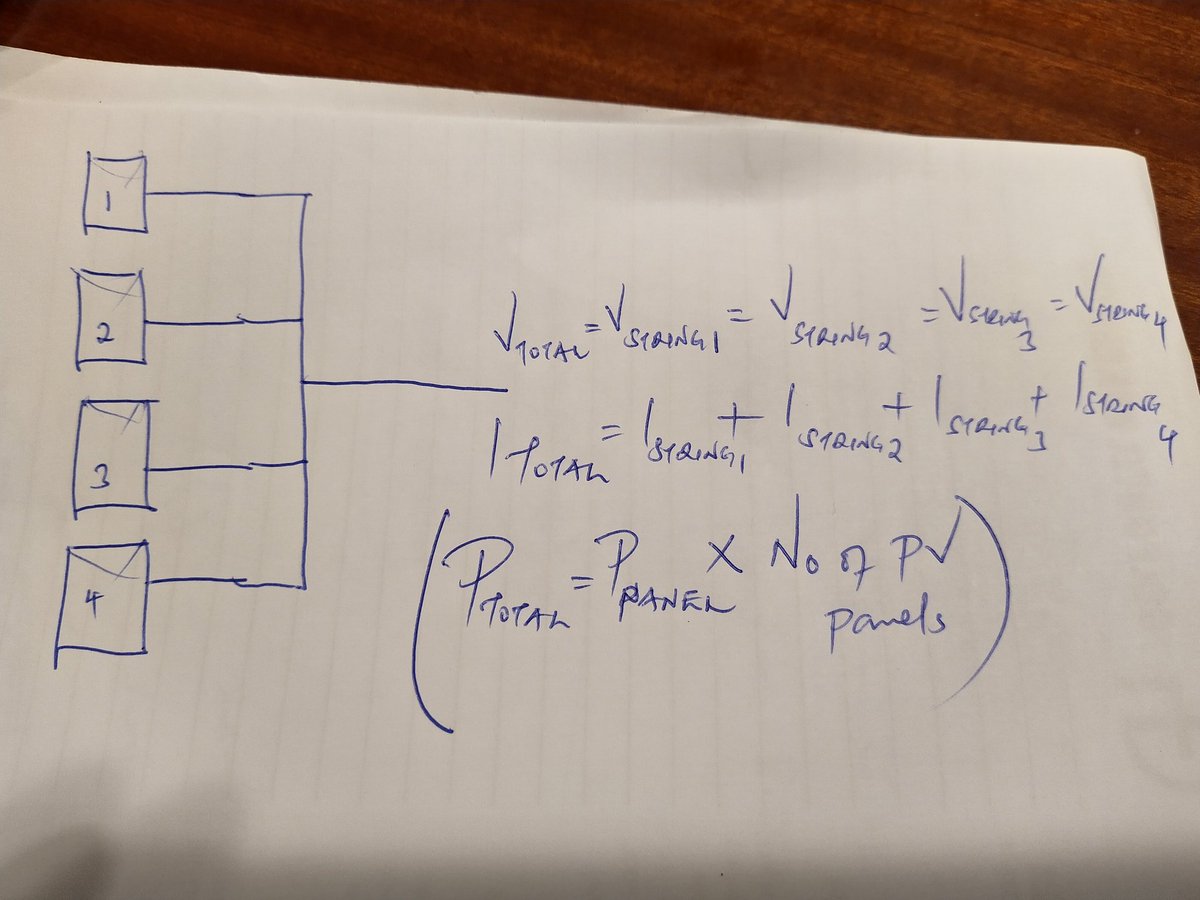

Depending on the load( we will get here soon enough), you can have an array of PV connected together either in series or parallel (depending on whether you want high voltages or high current). There is a science on how they are installed

Solar PV produce DC power, so in most cases you will find yourself needing an inverter to convert the DC power to AC power. Nowadays though, to avoid that conversion from DC to AC (there are losses involved hence loss of power) we have DC electronics and lightings

Solar power generation depends on the intensity of the sun on the panels. Please Note: it& #39;s sunlight, not heat from the sun! It& #39;s the reason you will hear someone ask mbona hapa kuna jua Kali na solar haifanyi. Sunlight! Sunlight!

We will also get here. Effects of temperature

We will also get here. Effects of temperature

Three common types of Solar PV;

1. Polycrystalline - pure form of Silicon. Best(Very blue in colour). Very efficient(wierdly, performs at only 14% efficiency)

2. Mono crystalline

3. Amorphous - Worst! Mostly made from mabaki when making Polycrystalline. In most cases blackish

1. Polycrystalline - pure form of Silicon. Best(Very blue in colour). Very efficient(wierdly, performs at only 14% efficiency)

2. Mono crystalline

3. Amorphous - Worst! Mostly made from mabaki when making Polycrystalline. In most cases blackish

Disadvantages of PV systems;

1. Cost - it& #39;s capital intensive on startup. Simple home setup will require around 100-200k, while REA charges you 35k for Kenya power last mile connection.

2. Weather dependent - without sunshine you are screwed!

3. Storage is very expensive (PTO)

1. Cost - it& #39;s capital intensive on startup. Simple home setup will require around 100-200k, while REA charges you 35k for Kenya power last mile connection.

2. Weather dependent - without sunshine you are screwed!

3. Storage is very expensive (PTO)

In most cases you will have to invest in batteries(commonly known form of storage), which fairly expensive. As you know, solar energy cannot be stored, so you convert them into other forms of energy. If the PV is producing excess power and your batteries are full it goes to waste

Two commin types of installation;

1. Roof mounted - panels structure mounted on the roof

2. Stand alone - Solar support structure mounted on the ground

Oh, by the way... Disadvantage 5 - Theft. Zinaenda kuenda, especially ushago. Vandalism cases very rampant in rural areas

1. Roof mounted - panels structure mounted on the roof

2. Stand alone - Solar support structure mounted on the ground

Oh, by the way... Disadvantage 5 - Theft. Zinaenda kuenda, especially ushago. Vandalism cases very rampant in rural areas

Three types of Solar PV system;

1. Stand Alone - No grid. Power fully dependent on solar PV generator

2. Hybrid system - an integrated system comprising of Solar PV system and Grid/Backup generator. In most cases it& #39;s done to reduce cost, and have essentials on clean power

1. Stand Alone - No grid. Power fully dependent on solar PV generator

2. Hybrid system - an integrated system comprising of Solar PV system and Grid/Backup generator. In most cases it& #39;s done to reduce cost, and have essentials on clean power

Clean power - Power from solar PV. Clean by virtue of very little environmental impact. Little or no emissions; little or no pollution

3. Grid tied system - this is like what we currently have in Garissa, whereby Solar PV feeds the grid during production. This is installation on Large scale so we won& #39;t focus much on it. But simply put Solar PV plant feed the grid.

In stand alone systems in most cases we will have energy storage forms, like batteries. For a grid tied system, power is only produced when there is sufficient sunlight and in most cases at night stands generators support the load or individuals do their own backups

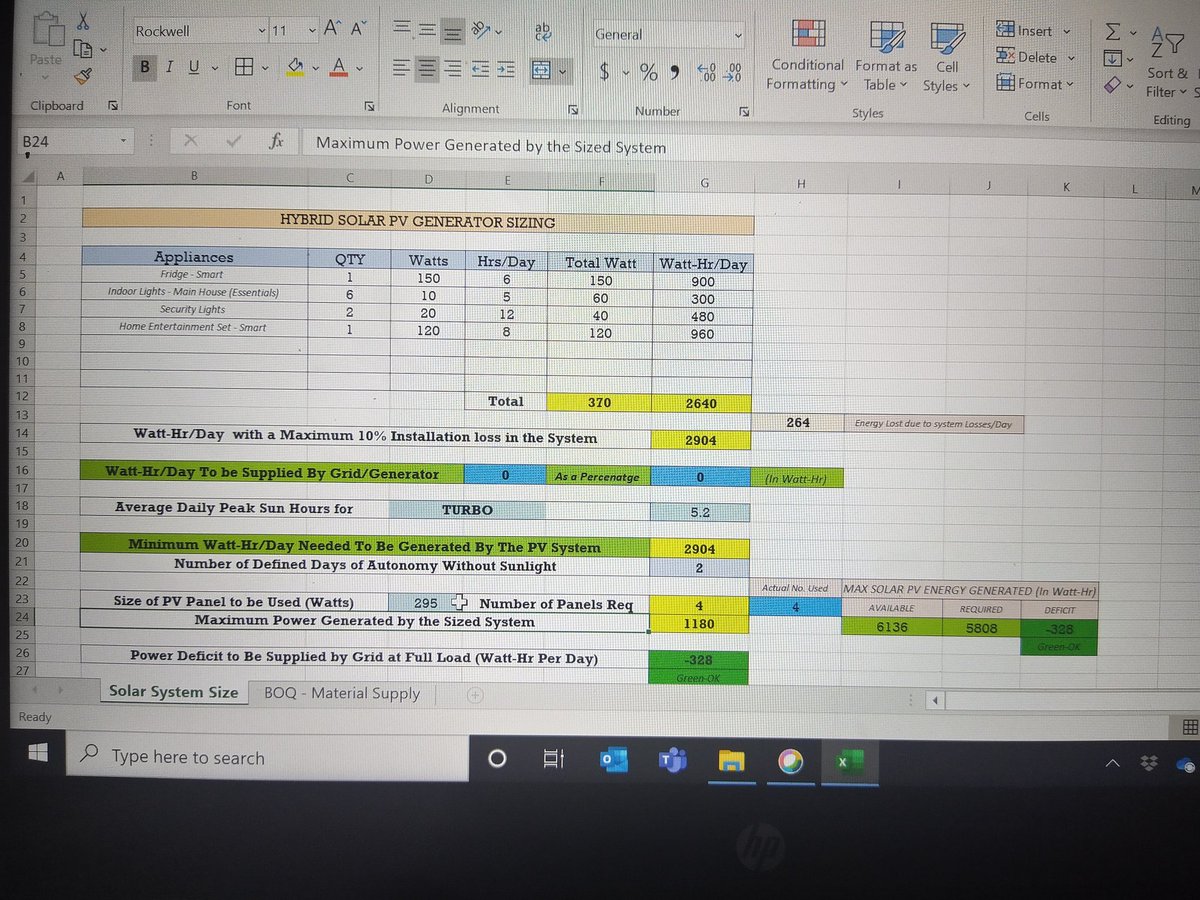

Now, we can now start sizing our Solar PV generator! So, what determines the size of the PV we are going to install? This is usually the tricky part. Most of the time you get the question "nikiweka solar ya 30k, itakaa siku ngapi?" Size is determined by load, not cost

Something called a Load Profile - this determines the actual consumption of your household. You need to decide what will be powered by solar. For a simple domestic setup, it& #39;s usually advisable to have your lights, TV/home entertainment and Fridge on Solar, essentially the basics

Why do I say so? With solar, the more the heavy consumer, the larger the PV size and the higher the cost esp on storage batteries. One thing that needs to come out clear with backup, there need to be a change of lifestyle, unless you can afford it.

When it comes to backup, cookers, iron boxes, instant showers, microwaves are a luxury. We will do a calculation to see the difference in system size something like an iron box has, as much as it& #39;s used for only say 15mins in a day, or a microwave for 10mins in a day

first we need to understand the terms used. Voltage(V), which is usually 240V. Current (A) which is a measure of what your electronic consumes and power(W) which is the consumption. I have used very basic definition of the above for simpler understanding. So P=V*1 (watts, W)

Load can be given in terms of voltage and Current, or Voltage and Power. Whichever way, the most important is knowing how to get the power. e.g this lamp which consumes 40Watts

Or this charger that has been given a rating in terms of Voltage and Current (multiply the two and get power)

Second definition is energy,

E=P*Hours (kWh). This will give us the amount of energy consumed over a period of time. E.g for my 40watt lamp, if I use it for 5hrs in a day my energy consumption is 40*5=200wh. This is what will reflect on my electricity bill. E is what we require

E=P*Hours (kWh). This will give us the amount of energy consumed over a period of time. E.g for my 40watt lamp, if I use it for 5hrs in a day my energy consumption is 40*5=200wh. This is what will reflect on my electricity bill. E is what we require

4 methods of determine energy consumption (creating a load profile);

1. Manual calculation

2. Using a Kill-A-Watt meter

3. Approx from monthly electricity bill for post paid, and determination by number of tokens used per month for pre paid

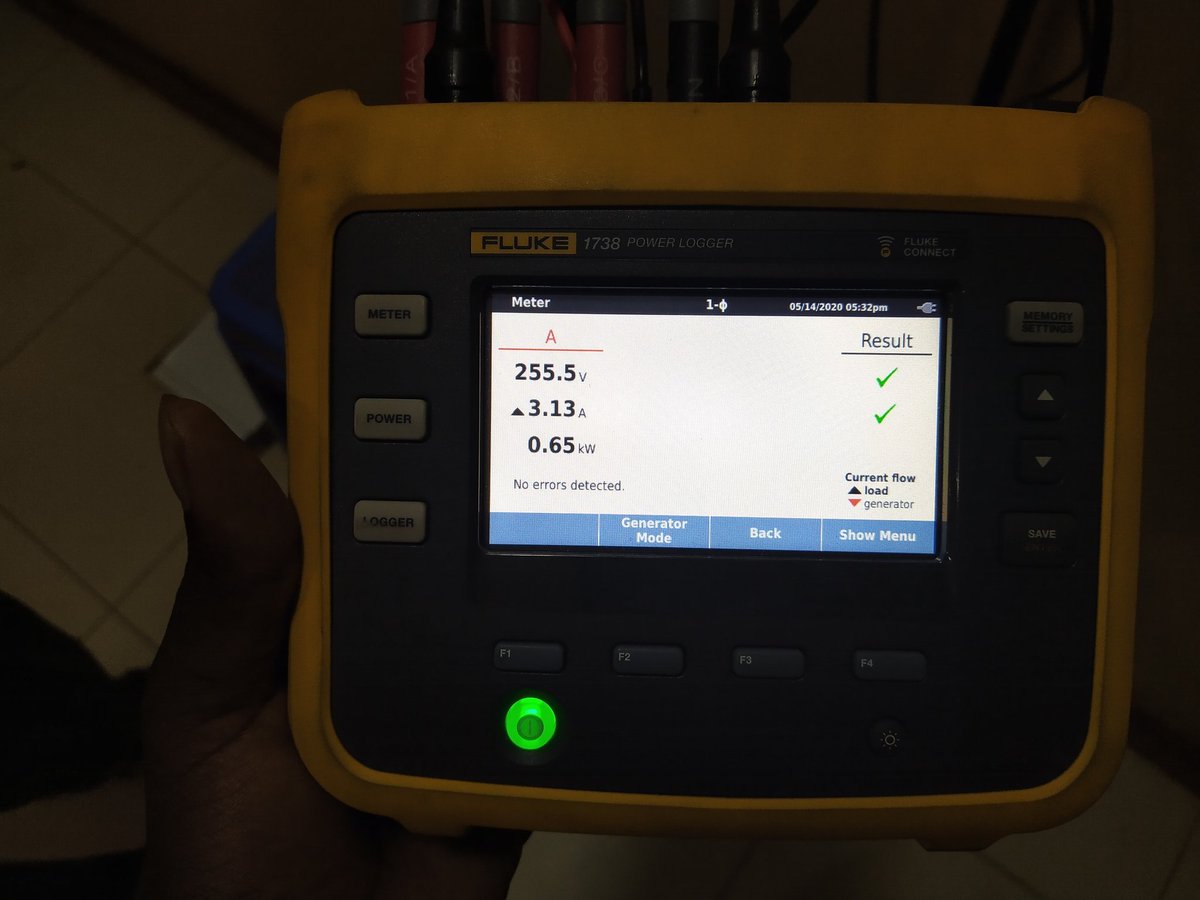

4. Using an energy logger(what I use)

1. Manual calculation

2. Using a Kill-A-Watt meter

3. Approx from monthly electricity bill for post paid, and determination by number of tokens used per month for pre paid

4. Using an energy logger(what I use)

Manual calculation; using device power rating, multiplying by the number of hours of usage per day and the number of devices. This gives you the total power and actual energy consumed in a day

Kill-A-Watt Meter; demo video below, but plug in the device you want to test, it will give the voltage, current, the power and KWH(energy) based on how long you have run your meter. 24hrs per device should be ok. You then sum up all the power and Energy https://youtu.be/9jt1m0ulEiM ">https://youtu.be/9jt1m0ulE...

Approx from Elec bills; first, from your bill, 1 unit consumed equals 1kwH for post paid. 1 token unit equals 1kWH for pre paid. If you consume 4 token units per day, that& #39;s 4kwH per day. If your post pay bill was 200 last month and now it& #39;s 240, your monthly consumption is 40kwh

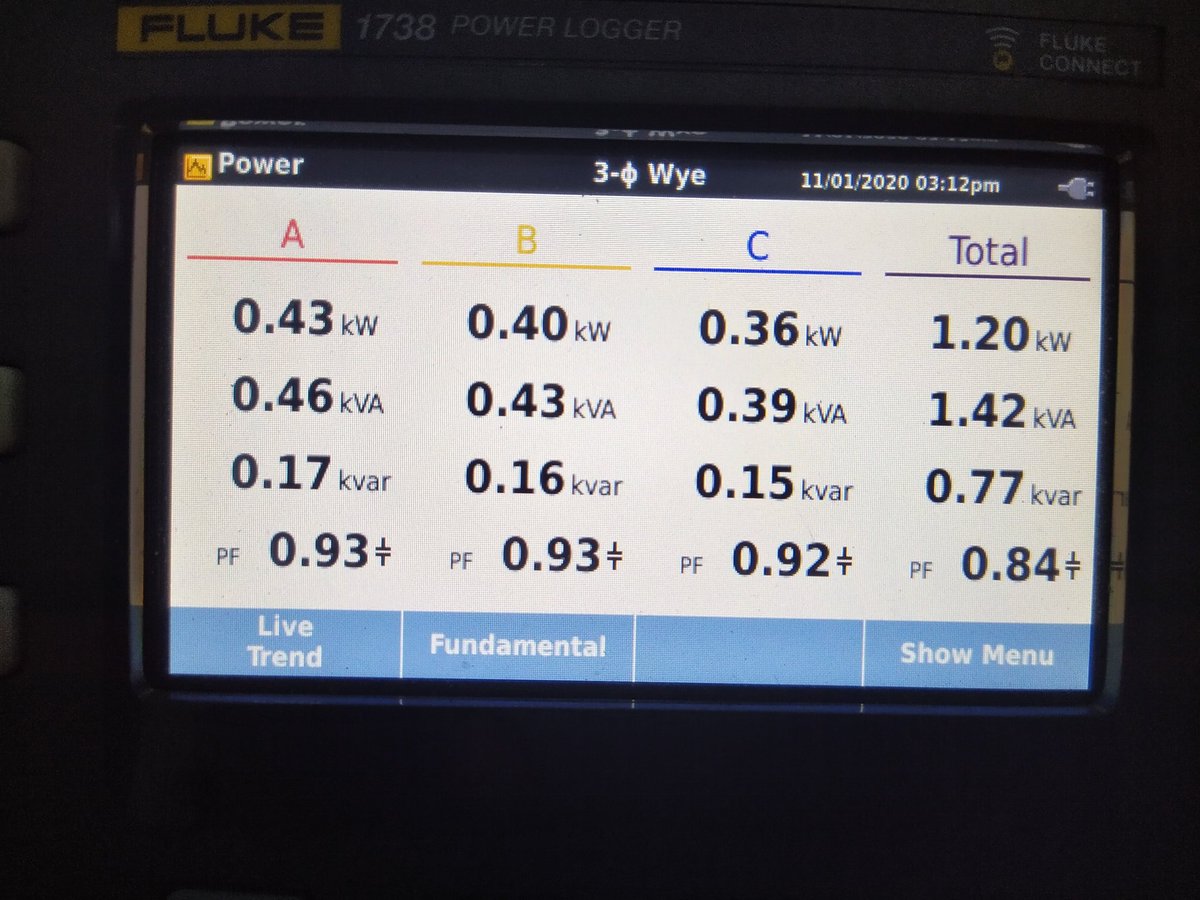

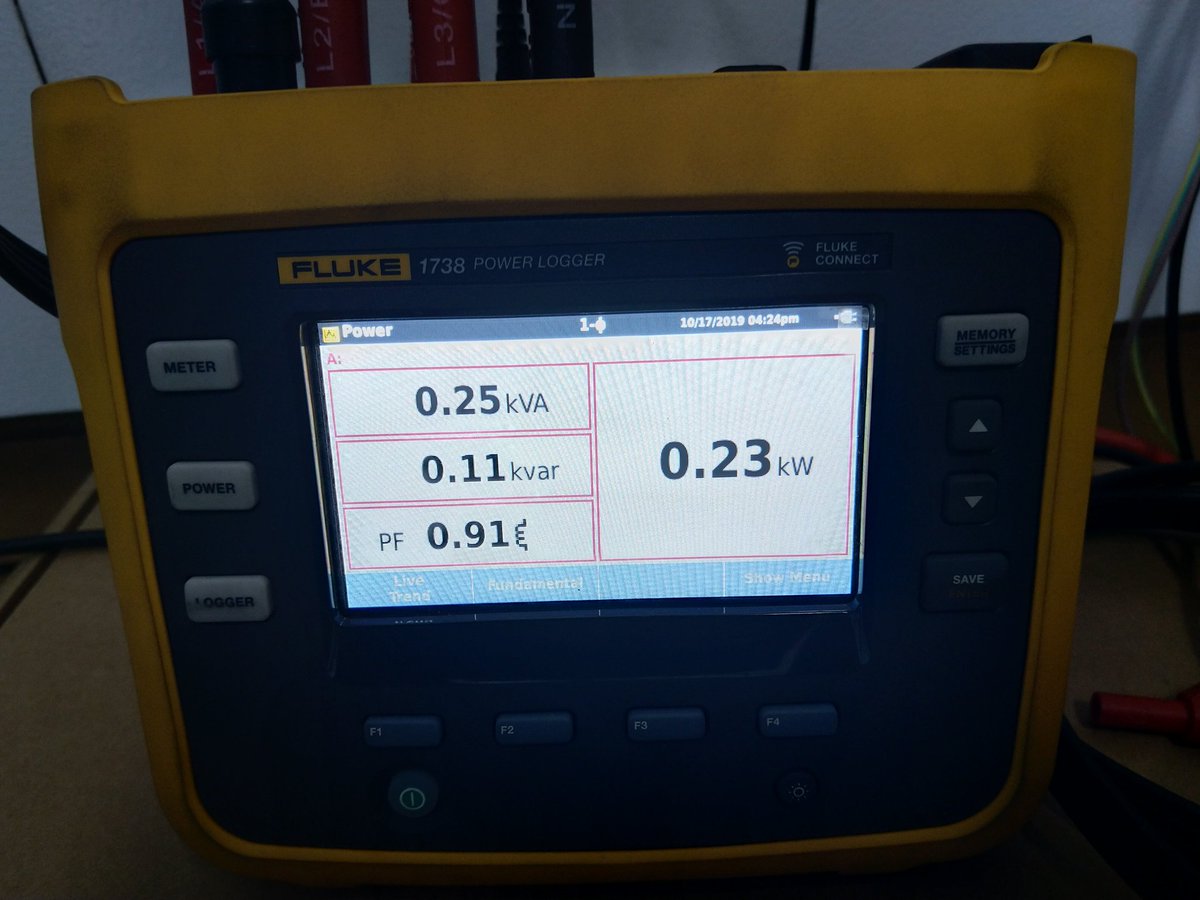

Using an energy logger; I use a Fluxe 1738 power logger. This gives me V, A, P and E and many other parameters(too much detail). It& #39;s plugged to the main incomer circuit breaker on the meter board and all essentials powered for a period of time (usually run it for atleast 24hrs)

By the way it& #39;s very important to know your load profile. It will help you understand your consumption better! Usiseme Tu KPLC wanakuibia and you have your lights on 24/7 na SAA yote unaoga maji Moto. Tawe! It makes you energy efficient.

There are devices with low ratings like bulbs that when used for a long period of time increase consumption. Always switch off lights and electrical devices when not in use! Do not hibernate, switch off! Save energy

One more thing; device efficiency. Always make sure you get high efficiency devices. In most cases it will be written as a percentage (always check datasheet). Most devices work at an efficiency of 0.86-0.9(86-90%). This is called power factor. The closer you are to 1(unity)...

...the better the performance of your device. e.g a device rated at 2000watts with a PF of 0.8 means 80% of the 2000 watts is used up the device, and the 20% is considered as losses(too much maths). One form of loss is heat dissipation. If your device is too hot when operating...

...it& #39;s not working smartly! It& #39;s the reason devices like heaters, kettles, orange bulbs(non energy savers), iron boxes have very high rating as compared to devices with more electronically made devices like TVs, fridges etc. Heat dissipators are very heavy consumers

It& #39;s very hard to get devices working at unity PF, but most smart devices nowadays operate as close to unity as possible.(I know a fridge that operates at 0.99 PF)

End of Part I. Jioni we start on Solar PV and Storage sizing. We work with the manual calculation I had done (minus microwave and Iron Box)

Power = 340 Watts

Energy = 3880 WattHour/3.88kWH

Already, from that you can tell you need 3.88 Kplc units daily to power your devices

Power = 340 Watts

Energy = 3880 WattHour/3.88kWH

Already, from that you can tell you need 3.88 Kplc units daily to power your devices

KPLC charge approx. ksh. 22 per kWH. monthly consumption for this household will be 22*3.88*30= ksh. 2,561 per month.

Note: the 3.88kWH is not constant. devices do not necessarily consume the whole rated power, goes lower at times but calculations are based on Max load

Note: the 3.88kWH is not constant. devices do not necessarily consume the whole rated power, goes lower at times but calculations are based on Max load

Reason why using a Power Logger is more accurate as compared to manual calculation. Gives you the exact Load

Haya, Lesson iendelee although most of what& #39;s remaining is practical bit(Did a 750Watts Solar PV system for domestic use in Bungoma in 2015). Will pass by kesho for some onsite demo. Hopefully it still works.  https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. But hatuwezi kosa kitu moja mbili ya Ku learn

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. But hatuwezi kosa kitu moja mbili ya Ku learn

Now, as we had discussed asubuhi there are two setups for solar PV installation commonly used for domestic use;

1. Off Grid Systems - No grid at all, pure solar PV system

2. Hybrid Systems - both Grid and Solar; You decide what % of load goes to solar. From the load profile.

1. Off Grid Systems - No grid at all, pure solar PV system

2. Hybrid Systems - both Grid and Solar; You decide what % of load goes to solar. From the load profile.

For our 3880Wh energy, if we say 60% goes to solar (essentially you are reducing your Kplc bill by 60%), we will size our system to be able to support 0.6 * 3880 = 2328Wh demand

If you are rich (lol), sukuma all your energy demand on Solar PV and only have KPLC come in when there is no much sunlight (cloudy and rainy season)

Now, site survey; 3 important factors to consider during a site survey;

1. Feasibility - is it implementable on site? Labda mjamaa anaishi umoja Kwa flats

2. Viability - does it make economical sense? If grid is stable, no need of off Grid system

3. Determine user requirements

1. Feasibility - is it implementable on site? Labda mjamaa anaishi umoja Kwa flats

2. Viability - does it make economical sense? If grid is stable, no need of off Grid system

3. Determine user requirements

For Viability, there are instances where the grid is very stable, with little or no blackouts! In such cases you only advise client to get a backup solution. In some instances client budget might not fit his requirements so you scale down a solution to fit his budget

During a site visit, we determine the following;

1. Solar PV orientation & roof analysis - Roof direction, inclination direction, roof type, installation room for batts and inverter, cable length etc

2. Shading analysis - study how the sun moves (there are several shading tools)

1. Solar PV orientation & roof analysis - Roof direction, inclination direction, roof type, installation room for batts and inverter, cable length etc

2. Shading analysis - study how the sun moves (there are several shading tools)

3. Financial analysis - Cost Vs ROI analysis

4. Load analysis - Again, verify and adjust requirements based on site survey. There might be a need to increase or reduce, based on how much sun we can harness

4. Load analysis - Again, verify and adjust requirements based on site survey. There might be a need to increase or reduce, based on how much sun we can harness

I have introduced two new concepts;

1. Inclination - solar PV tilt to maximise on sunlight; max yields when sun rays are perpendicular to the solar PV

2. Orientation - direction from the sun of which the solar panels should face to get max yields

This is where it gets interesting

1. Inclination - solar PV tilt to maximise on sunlight; max yields when sun rays are perpendicular to the solar PV

2. Orientation - direction from the sun of which the solar panels should face to get max yields

This is where it gets interesting

At the equator, the sun is essentially on top of us, so placing your panel flat basically gives you the best yields. We will talk about why it& #39;s not advisable.

People at the North and South now have to adjust the inclination and orientation to point towards the sun. Lucky us!

People at the North and South now have to adjust the inclination and orientation to point towards the sun. Lucky us!

For us at the equator, the panel orientation gives the best yield when they face the path of the sun(we will do a demo kesho)

Panels need to self clean, Mvua washes away the dust, leaves and material landing on the panels. It& #39;s the reason it& #39;s tilted, and not flat. Tilt angle again should be optimal so as to maximise on sun rays to the panels. Roofs already have a inclination...

... when you do your solar mounting structure on the roof, you play around the tilt angle to maximise on sun. It& #39;s the reason roof mounting installation are tricky. (challenges of roof installation). I get alot of complaints vile solar yangu haifanyi due to bad roof installation

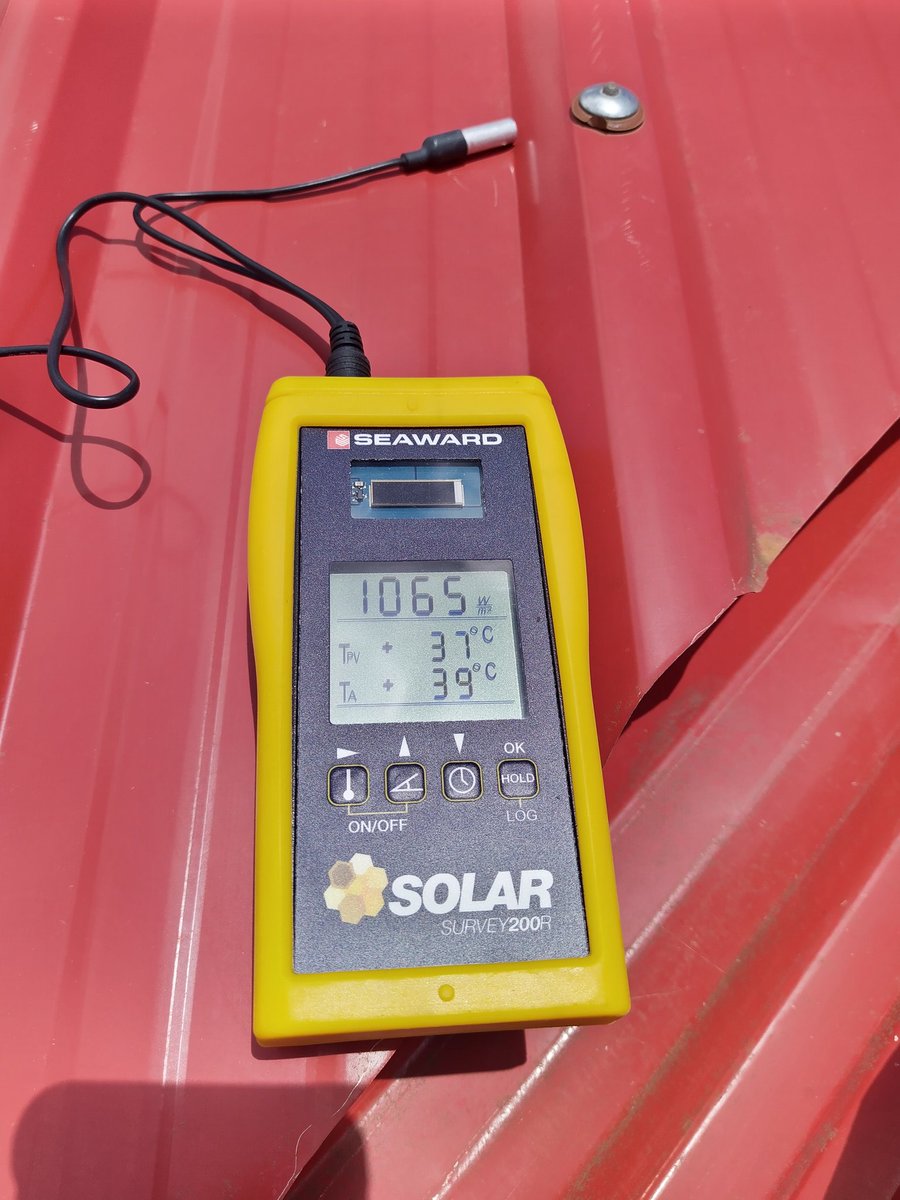

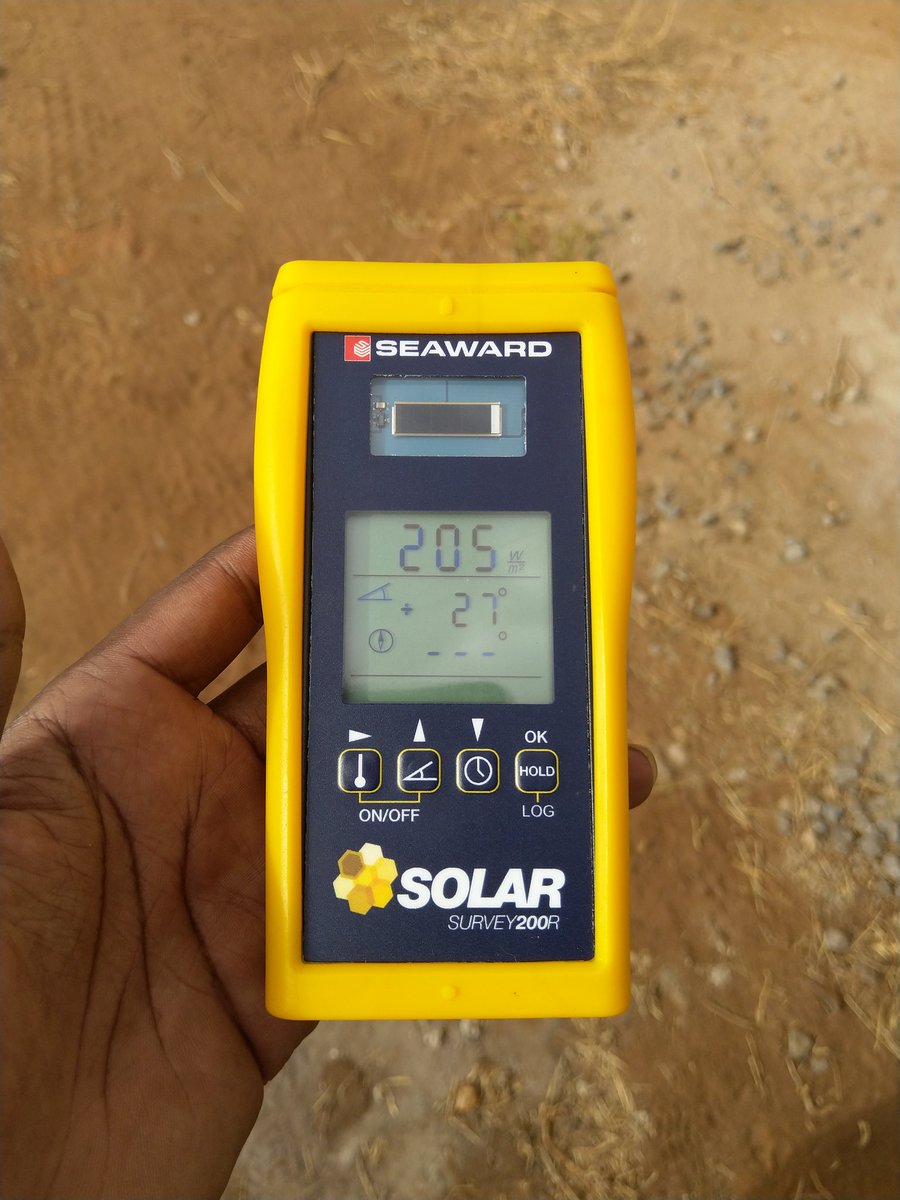

Inclination and Orientation bring about something called solar irradiance, which is a measure of power per unit area, which in our case the best production of PV is 1000W/M2! Too much theory, this will make sense once we get to practical session! Hopefully Bungoma has sunlight!

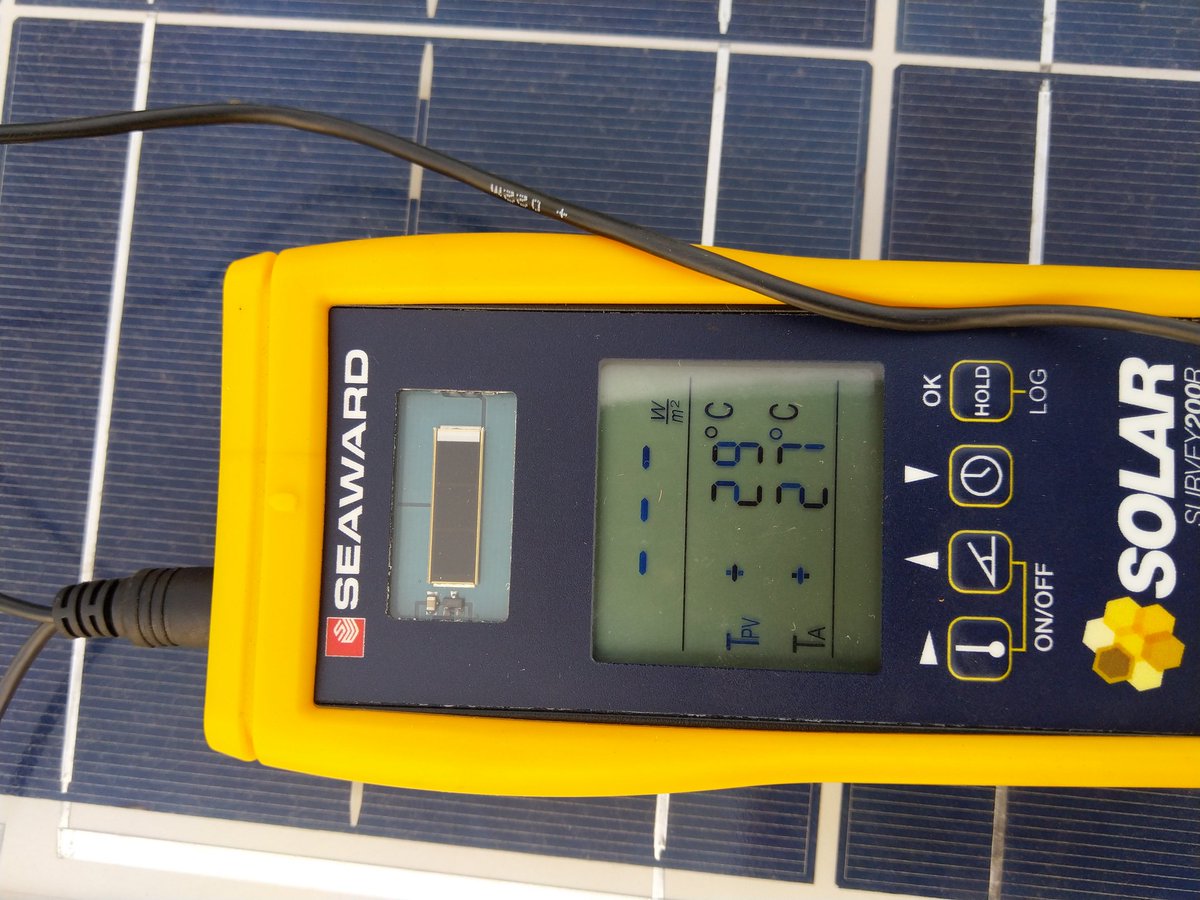

Gotten to BG but still too cloudy we can& #39;t do much. No production on the panels! So tutafanya Tu theory tena. This was my first ever solar project, a 750Wp system for domestic use.

From my meter, we can get inclination and orientation of the panels as displayed. You play around with the direction and slope of panels to get the best irradiance(if we had sun it would have displayed up there on the display of the meter).

There is also temperature aspect; Tpv for panel temperature and Ta ambient temperature (temperature ya nje). Let& #39;s talk about effect of temperature on panels and Solar power production

Now, PV modules are usually tested at 25°C(77F), therefore for every increase or decrease of temp affects output of the panel. Essentially, an increase in temp reduces panel efficiency by 10-25% (alot of maths) depending on installation location.

From basic physics, V=IR, where heat is a form of resistance in electrical systems(alot of maths), therefore for every rise in temp above 25°C, there is an increase in current, but a reduction of voltage. For every drop of temp below 25°C, Voltage increases and current decreases.

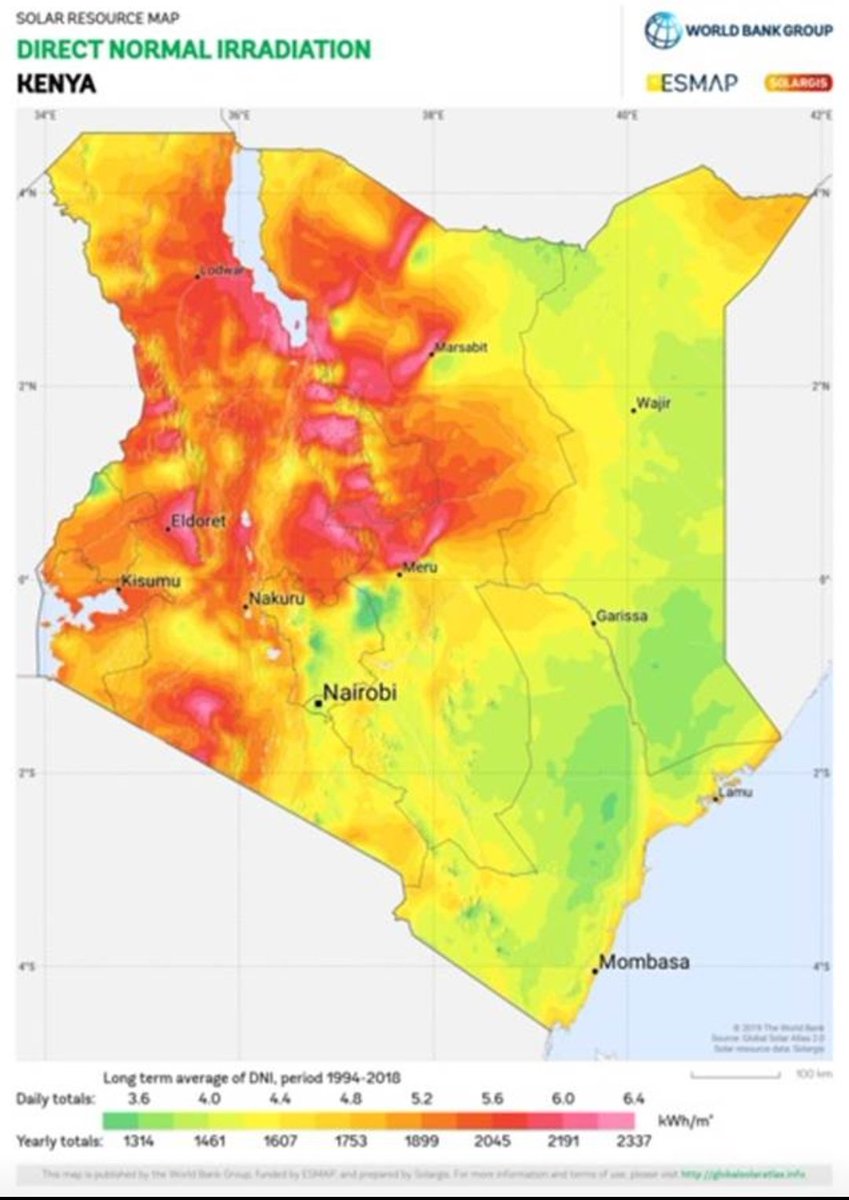

Each panel manufacturer usually has their own temp coefficient (Pmax). This shows by what percentage there is loss of power for every rise of temp by 1°C above 25°C at STC. It& #39;s the reason why a panel installed in Eldy will have a better output than one installed in Garissa

The only issue now is the cloud cover and Rains in Eldy are higher than Garissa. The sunlight might not be sufficient (sun hour per day in Garissa is around 7hrs, while Eldy is at around 5 hours). Note. Sun hours define when the PV will be doing max production. Not from 8am-5pm

Using the same temp concept, you can already tell why it& #39;s not advisable to have solar panels not installed directly on the roofs. Roofs usually go to temps as high as 50°C depending on location, so there will be a significant loss of production due to too much heat

For those who have been to Turkana, specifically Lokichogio or Lokitaung, cloud cover is almost nil, & the massive winds lower the temp to around 20°C. That& #39;s why I don& #39;t understand why govt opted to do the 55MW plant in Garissa, not Turkana. (cost of building new lines maybe?)

At the equator we get better radiation on the panels at 0°C(flat panel), reason we incline is for self Cleaning. When it rains, dust, leaves are washed off. You can see from the panels the effects of flat installation, dust accumulation affecting production due to cell blockage

Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma.  https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW

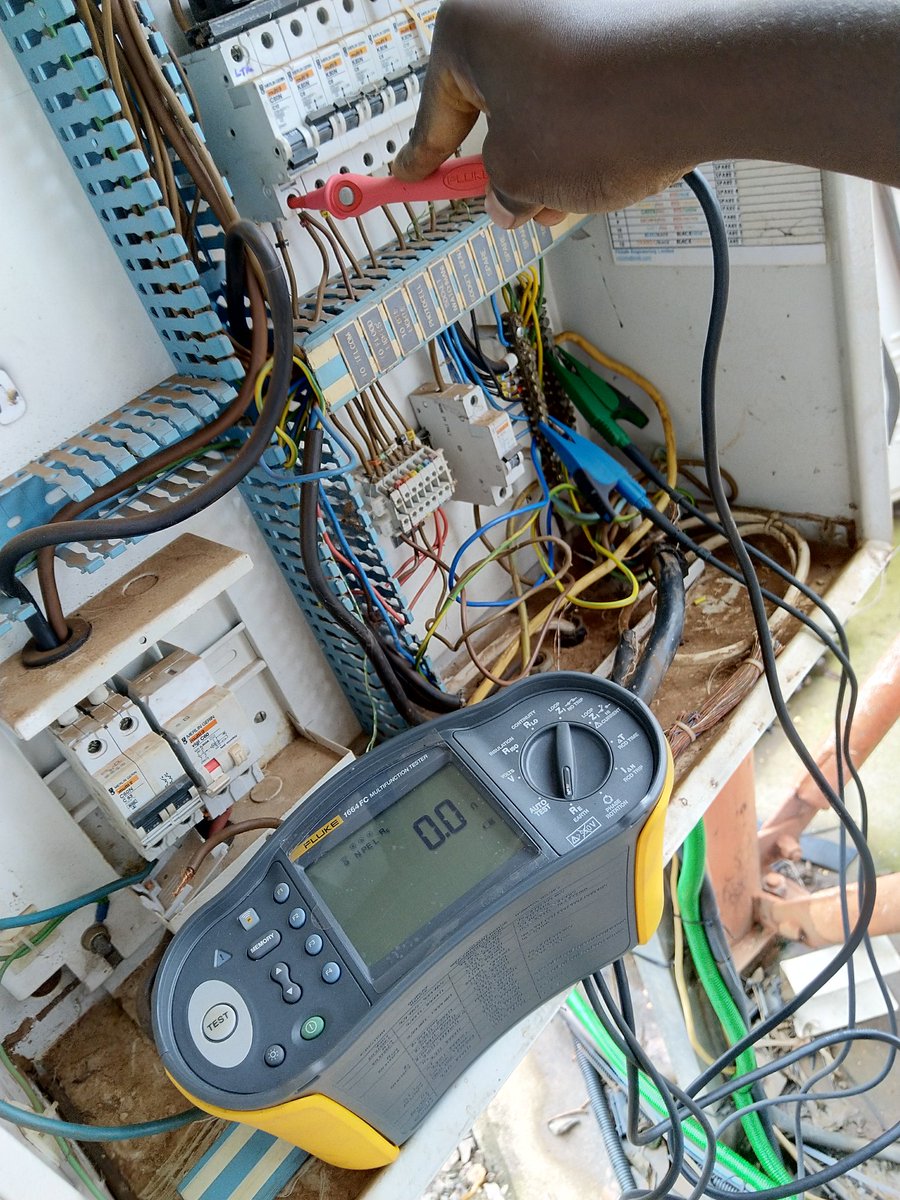

The difference wrong cabling/plate can do. Well done Earth pit(Earth Voltage 0V, 1.9Ohms Earth resistance), Well done 240V DB (Neutral-Earth ~ 0V, 1.9Ohms Ground resistance), but Neutral-Earth ~ 114V at Consumer End. Diagnosis - No continuity(stolen) between DB and Consumer Unit

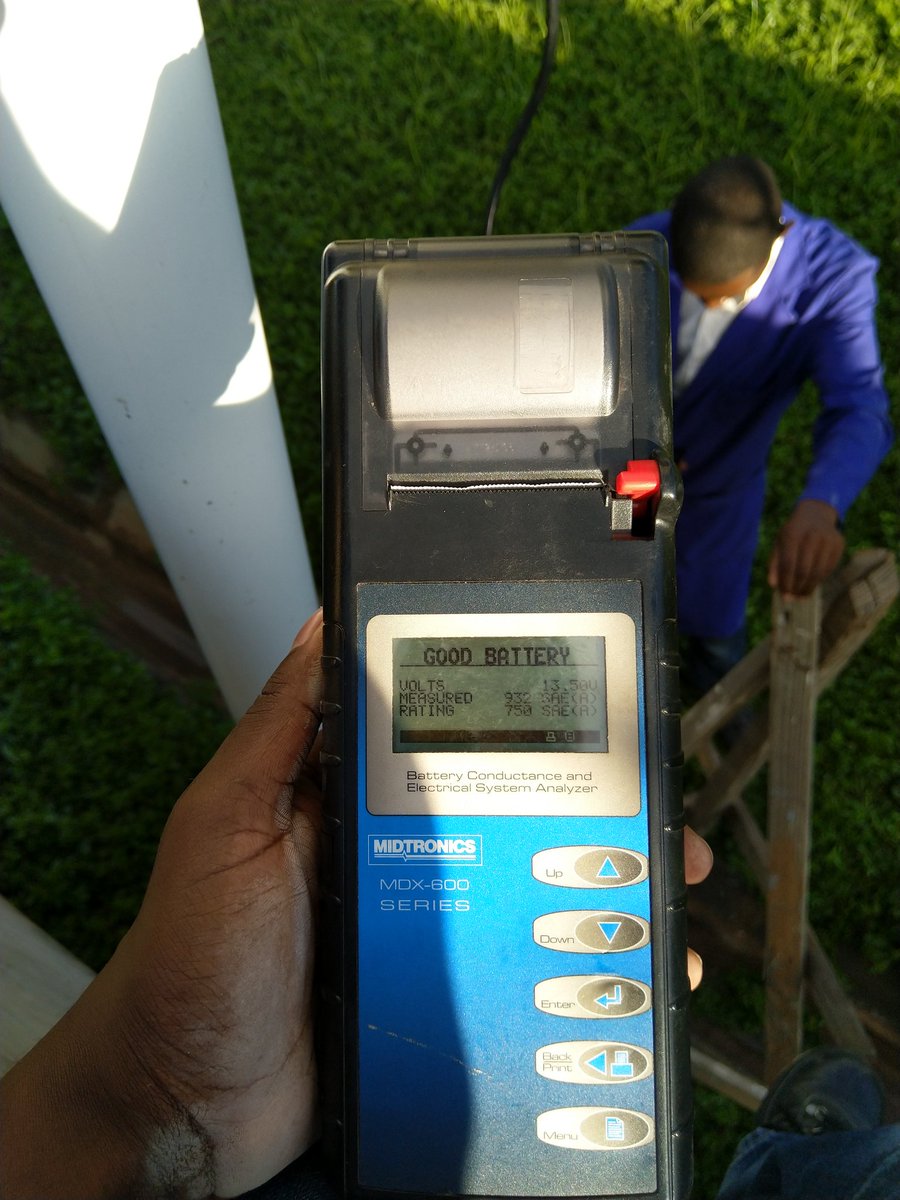

Today& #39;s lesson... Battery tests! 4 expected scenarios;

1. Good battery - Nominal Voltage, Sufficient Cycles

2. Good battery - Nominal voltage, depreciating Cycles

3. Good battery - Low Charge, Sufficient Cycles

4. Bad battery - Low Charge/Dead cells, Low Cycles

1. Good battery - Nominal Voltage, Sufficient Cycles

2. Good battery - Nominal voltage, depreciating Cycles

3. Good battery - Low Charge, Sufficient Cycles

4. Bad battery - Low Charge/Dead cells, Low Cycles

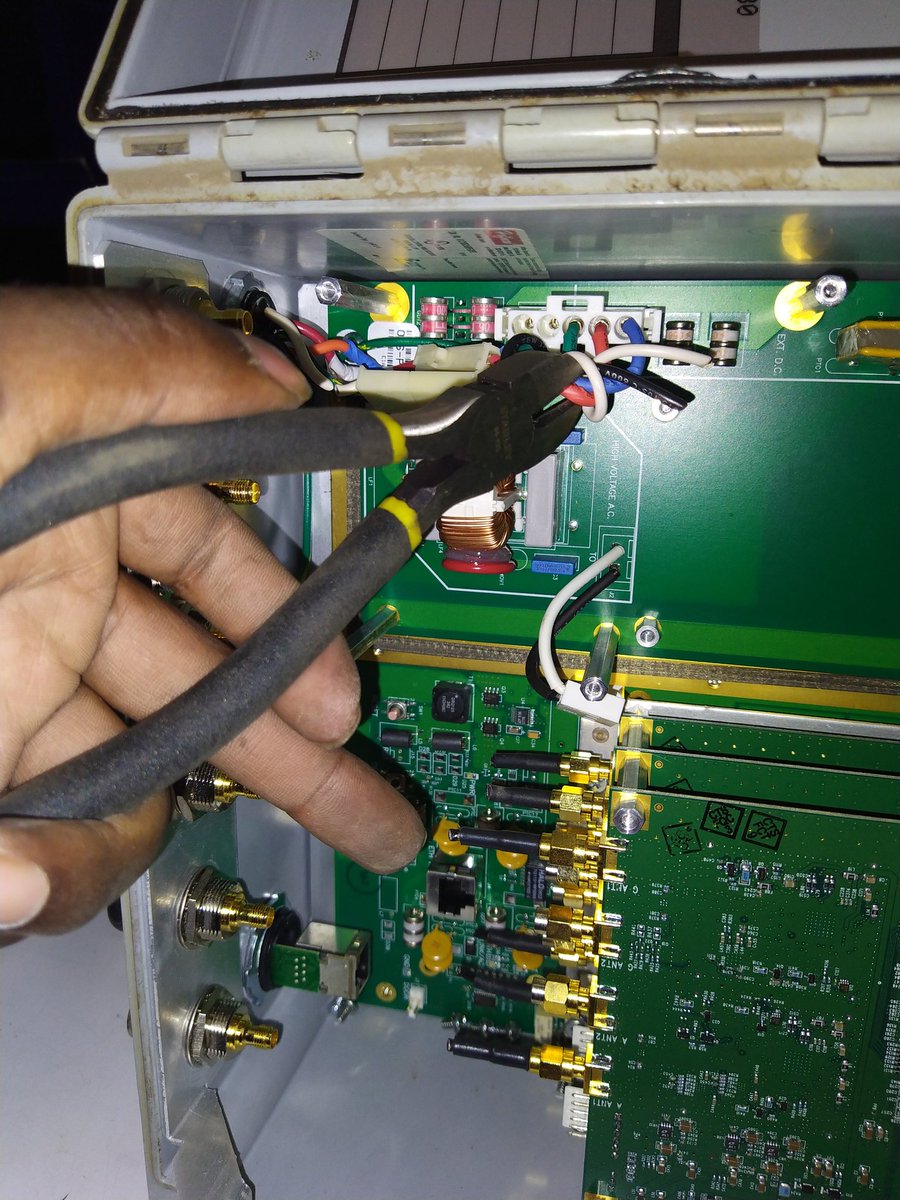

Doing a load profile for an Off-Grid IoT site! Connected all the equipment that will be powered in the BTS, including outdoor cabinet cooling fans that will be solar powered. Gives a more accurate data on the Fluke 1738 Data Logger as compared to manual calculation...

... Example the 6 cooling Fans have logged in total power of 80 watts on the data logger which might have been different on theoretical calculations, which means we would have over sized our system. The system needs to run for at least 3 days on no Solar...

...so my logger runs for 3 days to determine the amount of Energy consumed in that period. This will help size the solar PV system that will produce energy to power my system for a minimum 3 days

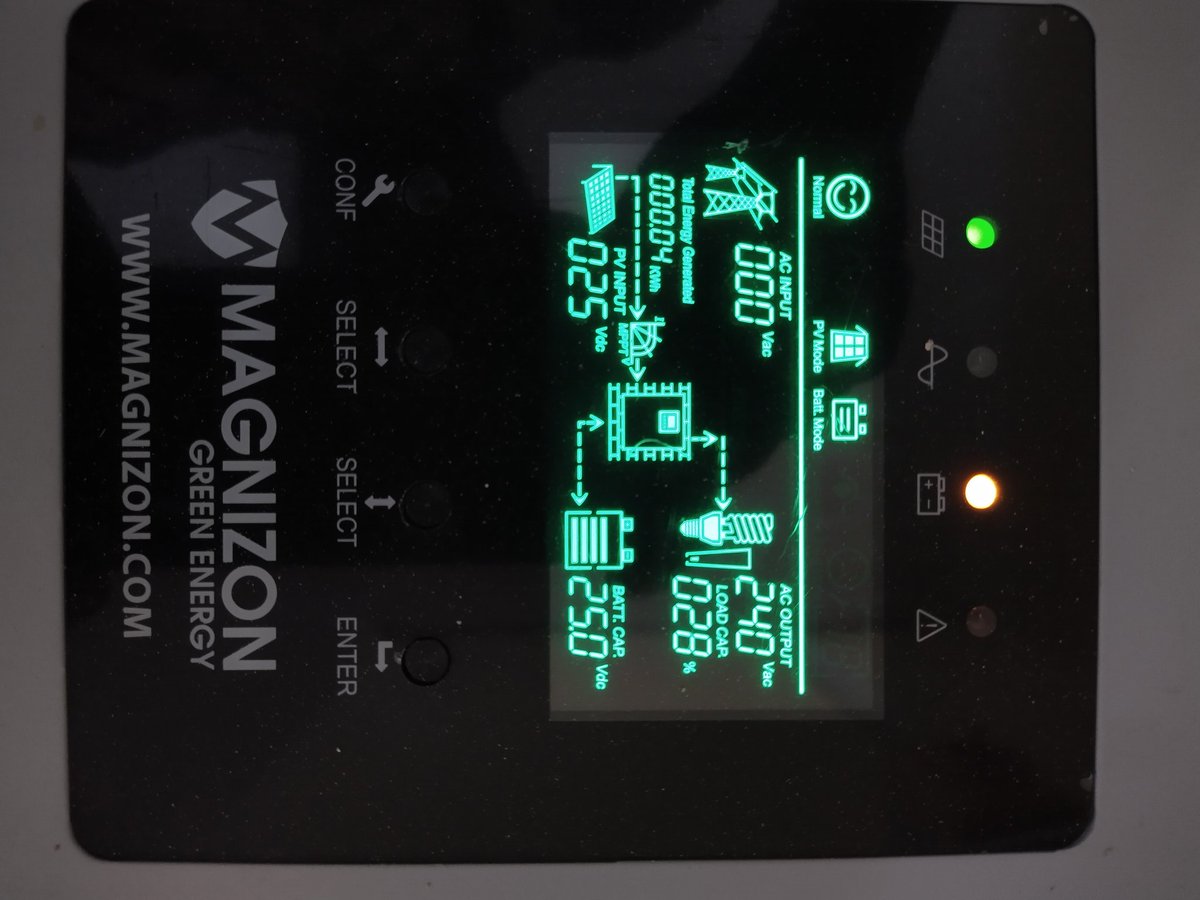

POC setup that& #39;ll run for 7 days. Slight modifications on the Cabinet; Solar Mounting Brackets to be fabricated on top. Used 310Wp PV, 1kVA Hybrid inverter(least size you can get with an inbuilt MPPT Charge controller) & 2~100aH batteries. Was too cloudy today for PV tests.Kesho!

Pia hii inahitaji routine maintenance otherwise itabeat! Clean panels during dry season (although when rain comes it washes away the dirt and dust ~ Solar panel tilting for self cleaning). Test battery for cycles

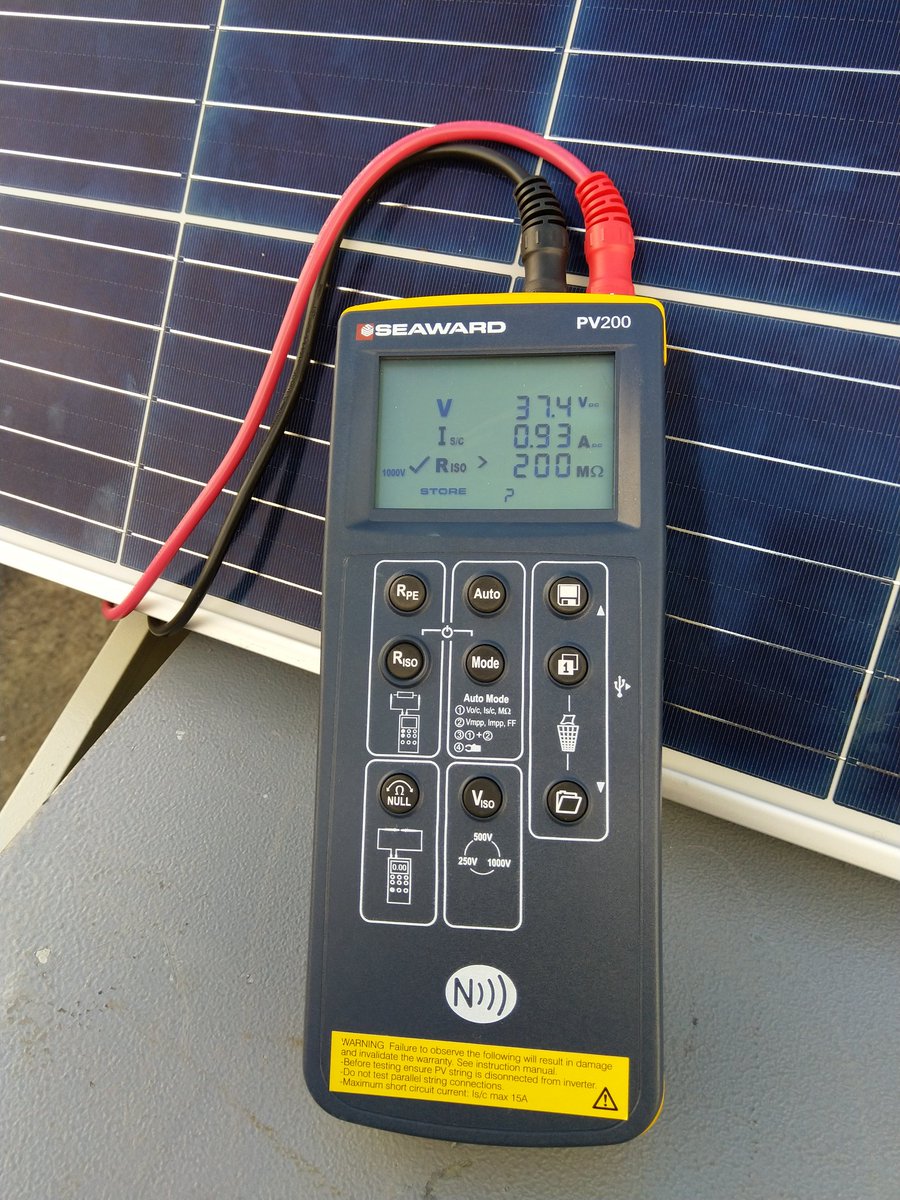

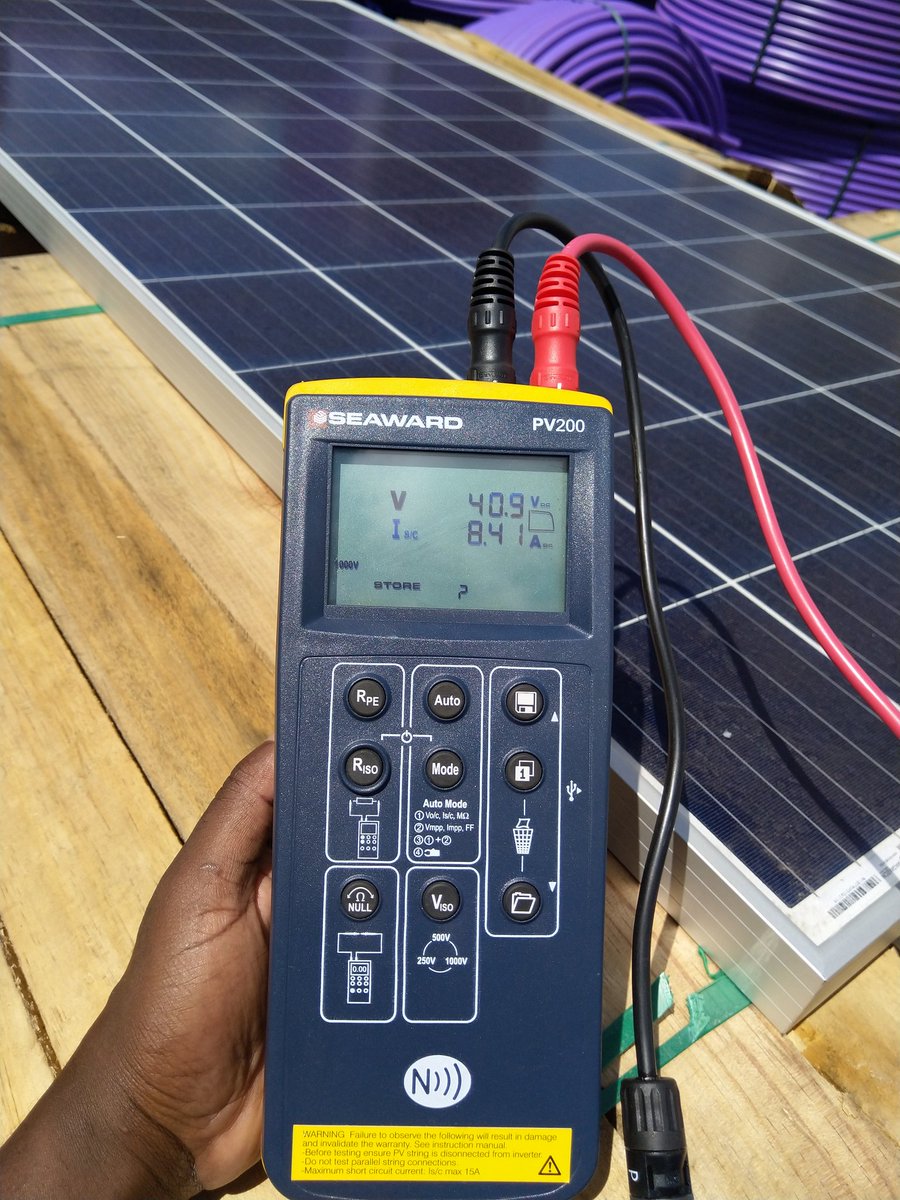

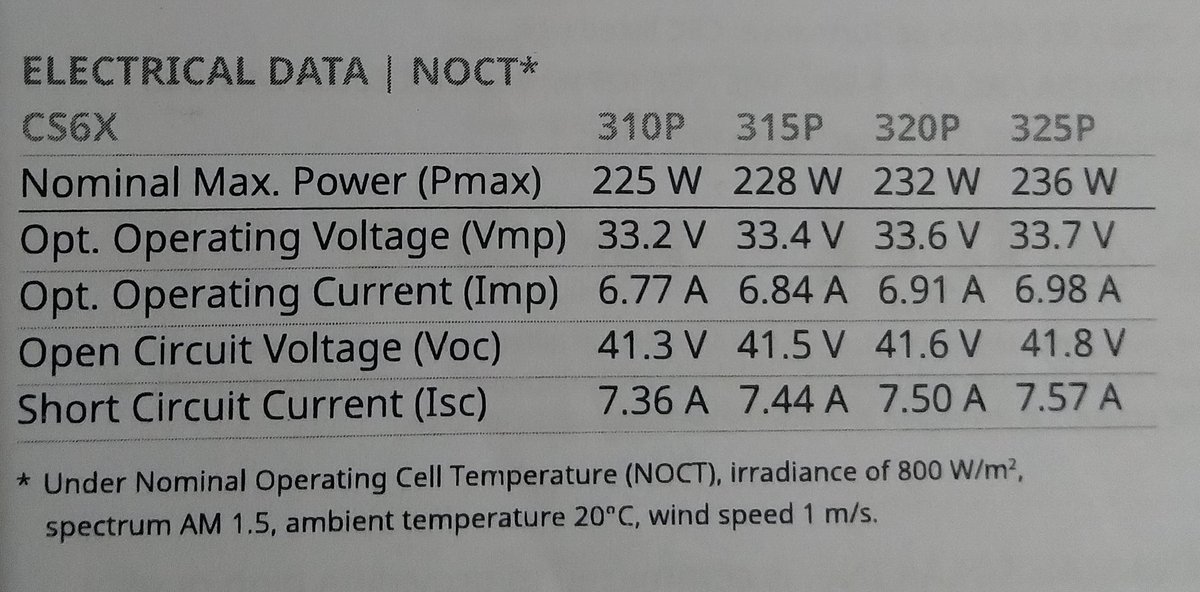

Looks like it& #39;s time we talk about STC(standard test condition), Open Circuit Voltage (Voc) and Short Circuit Current (Isc), Optimal operating Voltage(Vmp), Optimal operating Current(Imp), Nominal Max Power(Pmax), Module efficiency and Operating temperature of a PV module...

All these are usually found at the back of the PV module on the name plate and on the data sheet of the PV module.

Note: We have STC and NOCT. Will get to that shortly

Note: We have STC and NOCT. Will get to that shortly

Standard Test Conditions(STC) are lab conditions under which all PV modules are tested. Ideally a benchmark for comparing different types of PV modules

STC conditions;

1. Irradiance of 1000W/m2 which simulates peak sunshine on a PV directly facing sun in a day with no clouds...

STC conditions;

1. Irradiance of 1000W/m2 which simulates peak sunshine on a PV directly facing sun in a day with no clouds...

...

2. Ambient surface temperature of 25°C

3. Light spectrum that closely simulates sunlight: AM 1.5 G

Depending on where the installation is being done, you can achieve STC. Kenya being at the equator essential for atleast 4 Hours will attain an irradiance of 1000W/m2

2. Ambient surface temperature of 25°C

3. Light spectrum that closely simulates sunlight: AM 1.5 G

Depending on where the installation is being done, you can achieve STC. Kenya being at the equator essential for atleast 4 Hours will attain an irradiance of 1000W/m2

Nominal Operating Cell Temperature (NOCT) reflect the real site conditions under which a PV module will operate

1. Irradiance of 800w/m2 which take into account fact that PV don& #39;t always face the sun. Aconsiders atmospheric or geographic conditions that might diminish the sun

1. Irradiance of 800w/m2 which take into account fact that PV don& #39;t always face the sun. Aconsiders atmospheric or geographic conditions that might diminish the sun

2. Temperature considered is 45 (+/- 3) °C, as PV modules heat up considerably during operation (remember discussion on effects of rise in temperature, efficiency reduces)

3. The light spectrum is the same as for STC.

4. A windspeed of 1 m/s is considered, with air at 20°C

3. The light spectrum is the same as for STC.

4. A windspeed of 1 m/s is considered, with air at 20°C

Haya, twendelee...

Open Circuit Voltage (Voc) is the maximum voltage that the PV module can produce under standard test conditions, and is the value used determine how many PV modules that can wired while determining the Inverter or Charge Controller to be used. – bei La Paroni& #39;s

Open Circuit Voltage (Voc) is the maximum voltage that the PV module can produce under standard test conditions, and is the value used determine how many PV modules that can wired while determining the Inverter or Charge Controller to be used. – bei La Paroni& #39;s

Looks like I need to create some time we continue with our lesson...

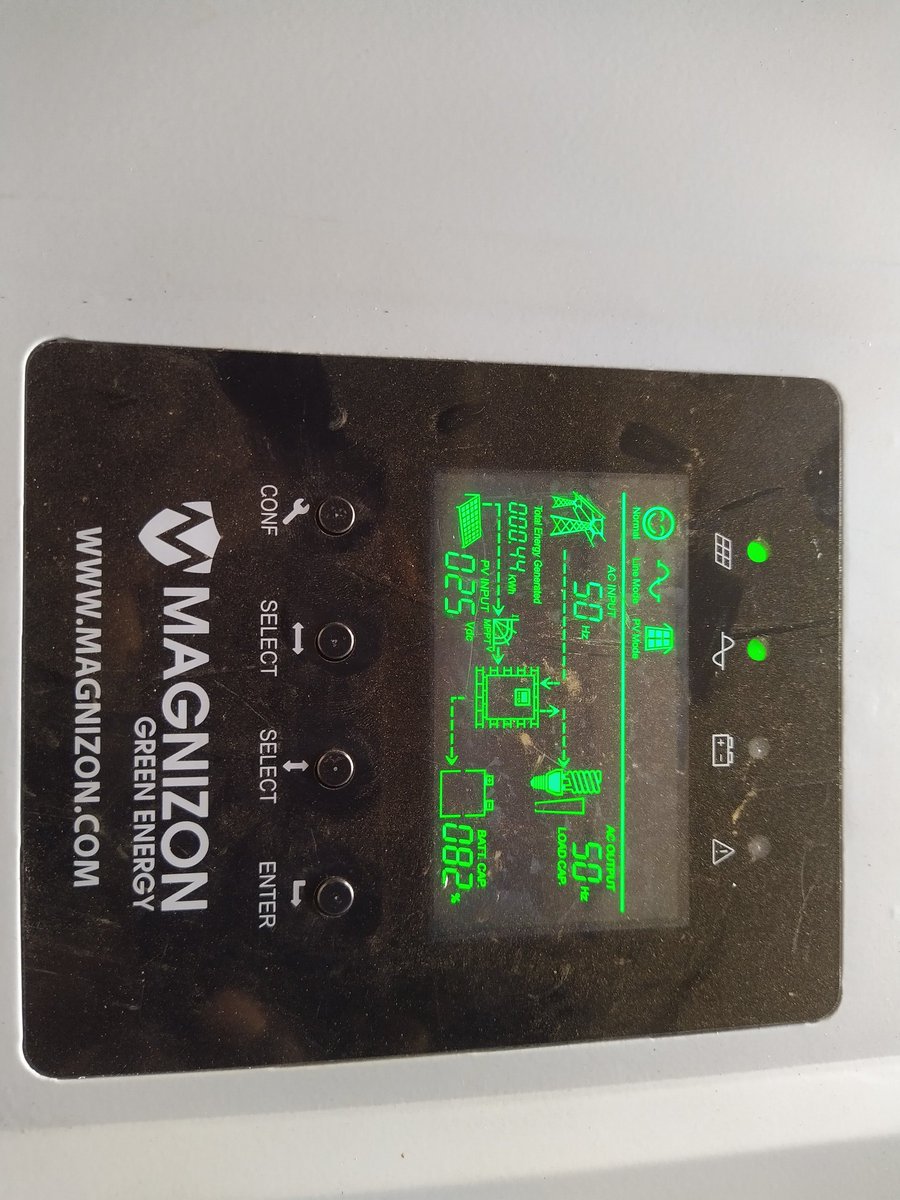

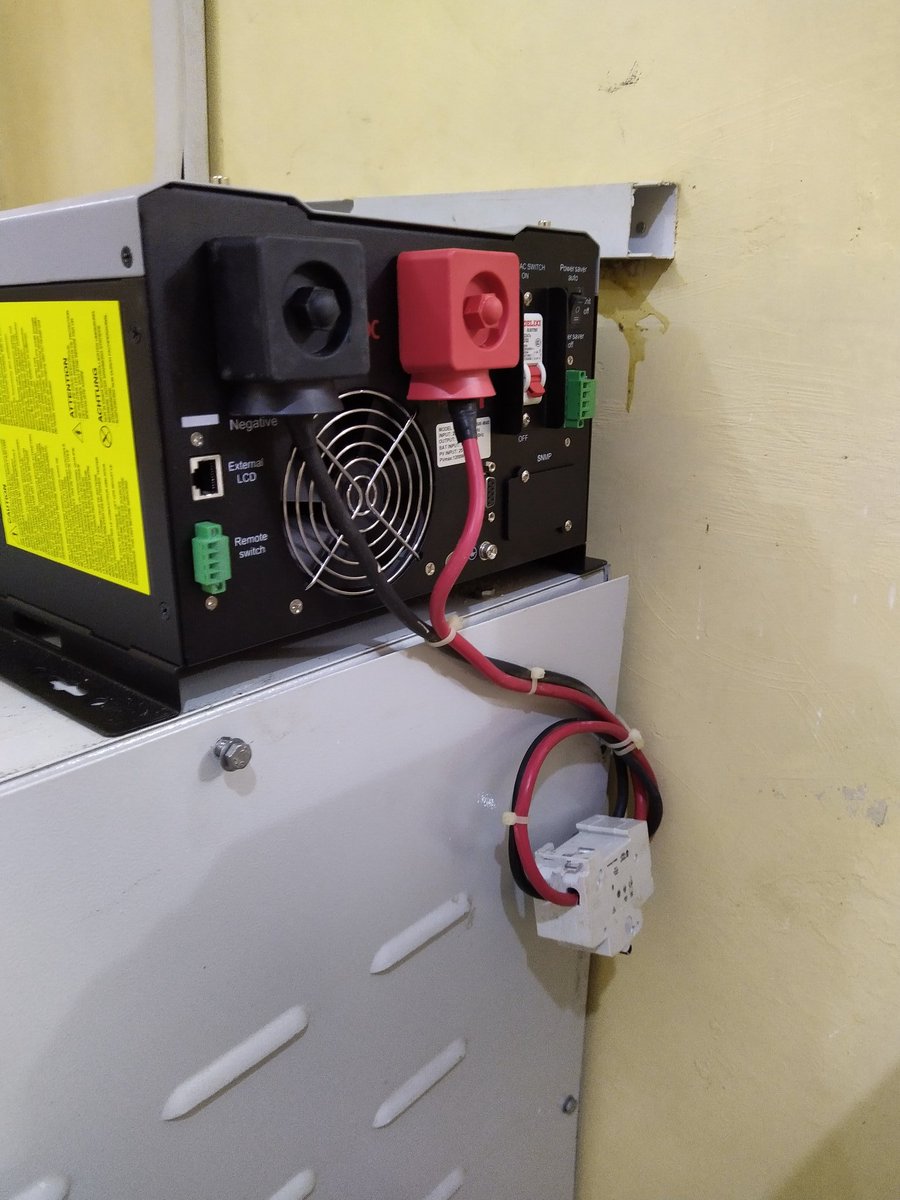

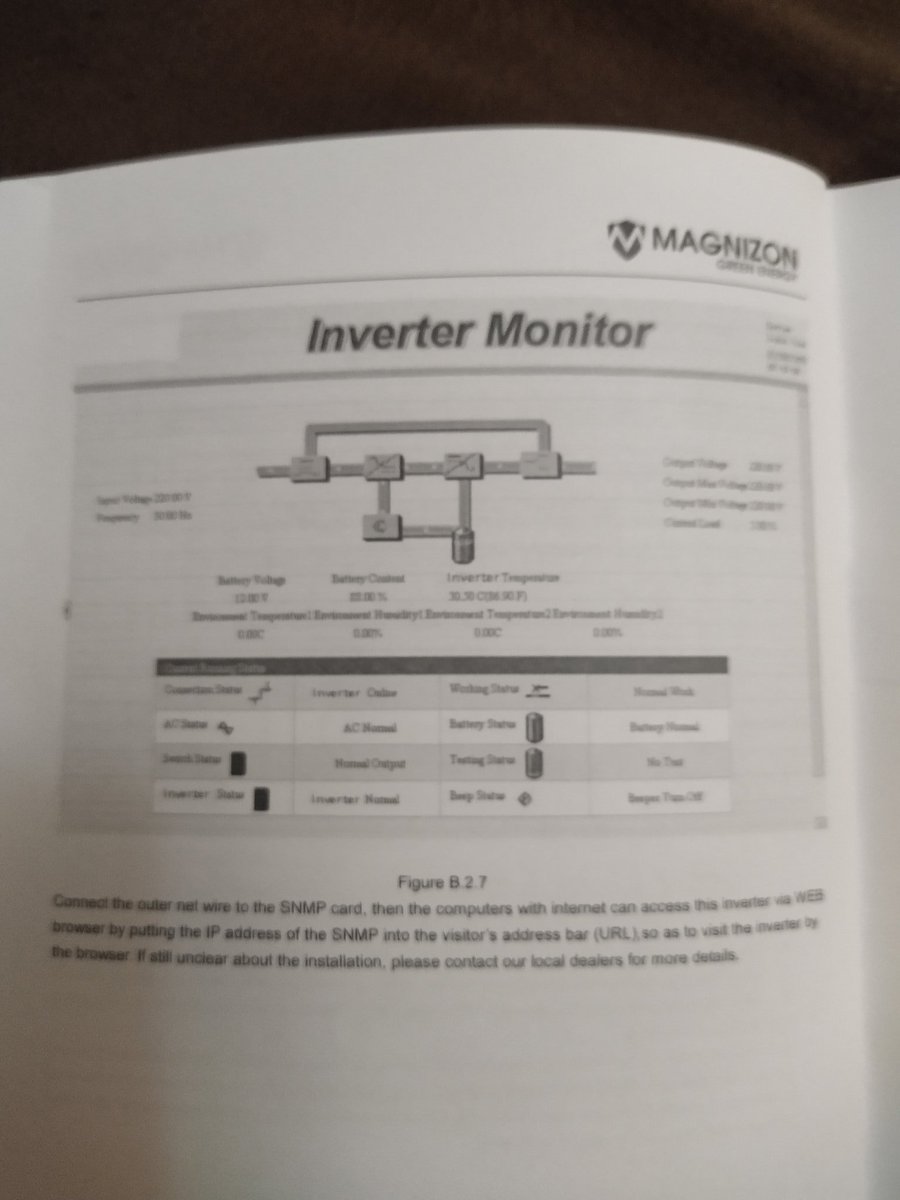

Gotten a newer version of Magnizon Hybrid inverter. APS Model. Transformer based. I like it already. Looks very compact and well packaged, and above all SNP enabled for remote monitoring (previous model you had to buy an SNP dongle separately). I like the wall mounts on the side

Did the grid (AC connection) bit today, with 2 banks of 24V/190aH batteries connected (Total of 380aH capacity). I got two 310Wp panels that I will connect tomorrow. Needed to have the batteries charged as they have been unused for quite some time (deep charging)

Done a kienyeji PV connection (for test only - left all my tools and cables in Juba. Will redo the whole setup later). 2Nos 310Wp panels in parallel. Should have sufficient current (peak ~ 20A) to fully charge the batteries. Setup the system to have PV power as priority.

Now, sometime back we had done some calculations on wire sizing (but in summary Cable size = 0.5 Max Current). This is where the challenge with most of these hybrid inverters come in (basically most solar products from Charger controllers to hybrid inverters...

From the Spec sheet of the Inverter (Voc or Max PV Voltage is 75V, Max current rating is 40A, system Voltage is 24V and Max PV power is 1200 Watts... Using a 300 Wp PV (done estimates from my 310Wp PV so as to have 4 PV panels connected, Voc-43.43V, Ioc-9.34A, Vmp-35.03 and...

... Imp-8.26A, Max no of PV I can connect in series to my Inverter equals 75/43.43=1.7~1 panel and Max PV I can connect in parallel to my Inverter equals 40/9.34=4.2~4 (always round off to the least whole number). That means 4Nos 300Wp panels in parallel. That gives Pmax=1200Wp..

Now, from the block diagram we can calculate the following parameters... Voc=43.43V with Isc=37.36A, and Vmp=35.03V with Imp=33.04A. therefore at this gives us a Pmax of = Vmax by Imax = 1157.39Watts. This is what the system will produce at peak efficiency. Now for my Isc...

...of 37.36A, I need a cable size of (37.36/2=18.62 which can be rounded off to 16mm.Sq. 25mm. Sq will be too big. From the PV termination point, max cable size that can fit is a 10mm.Sq(which is still forced to fit). That means undersizing the cable, hence cable warming up...

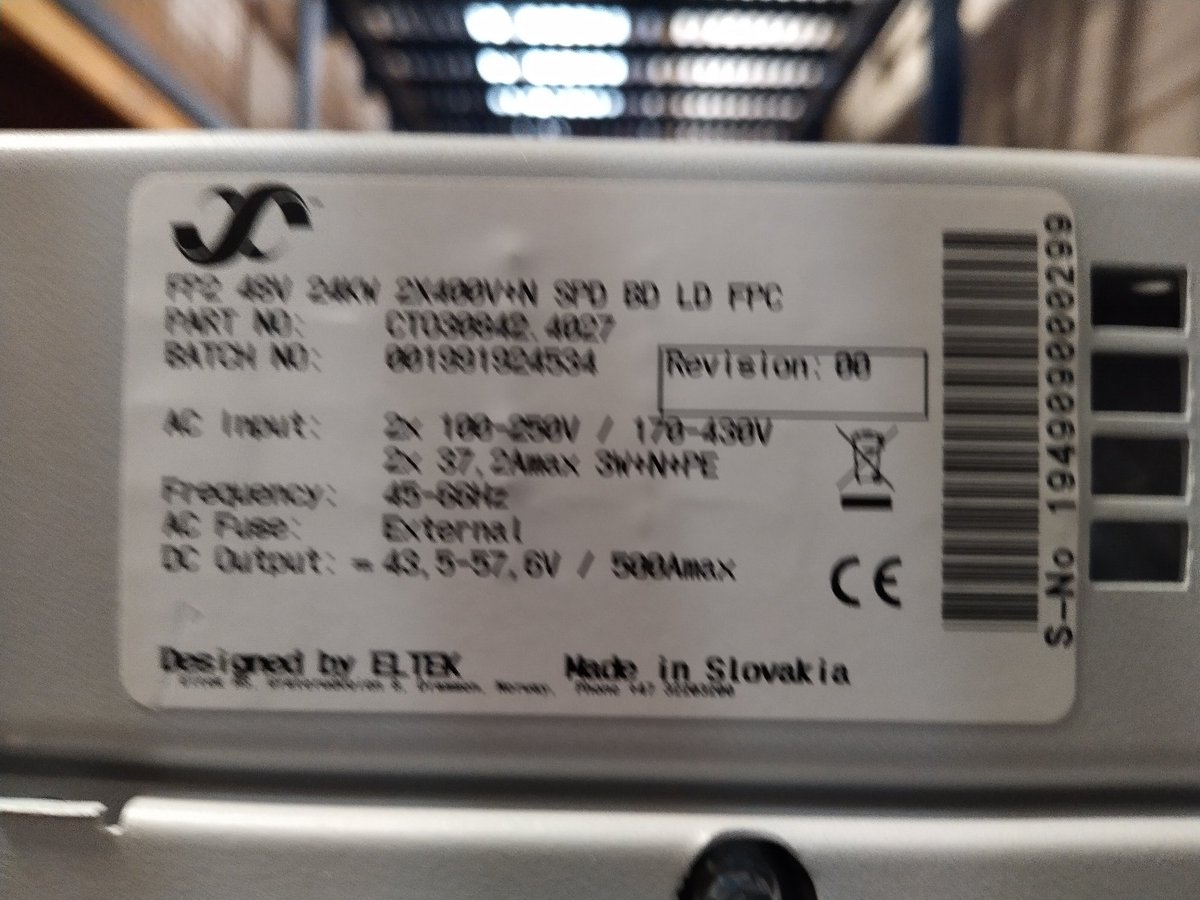

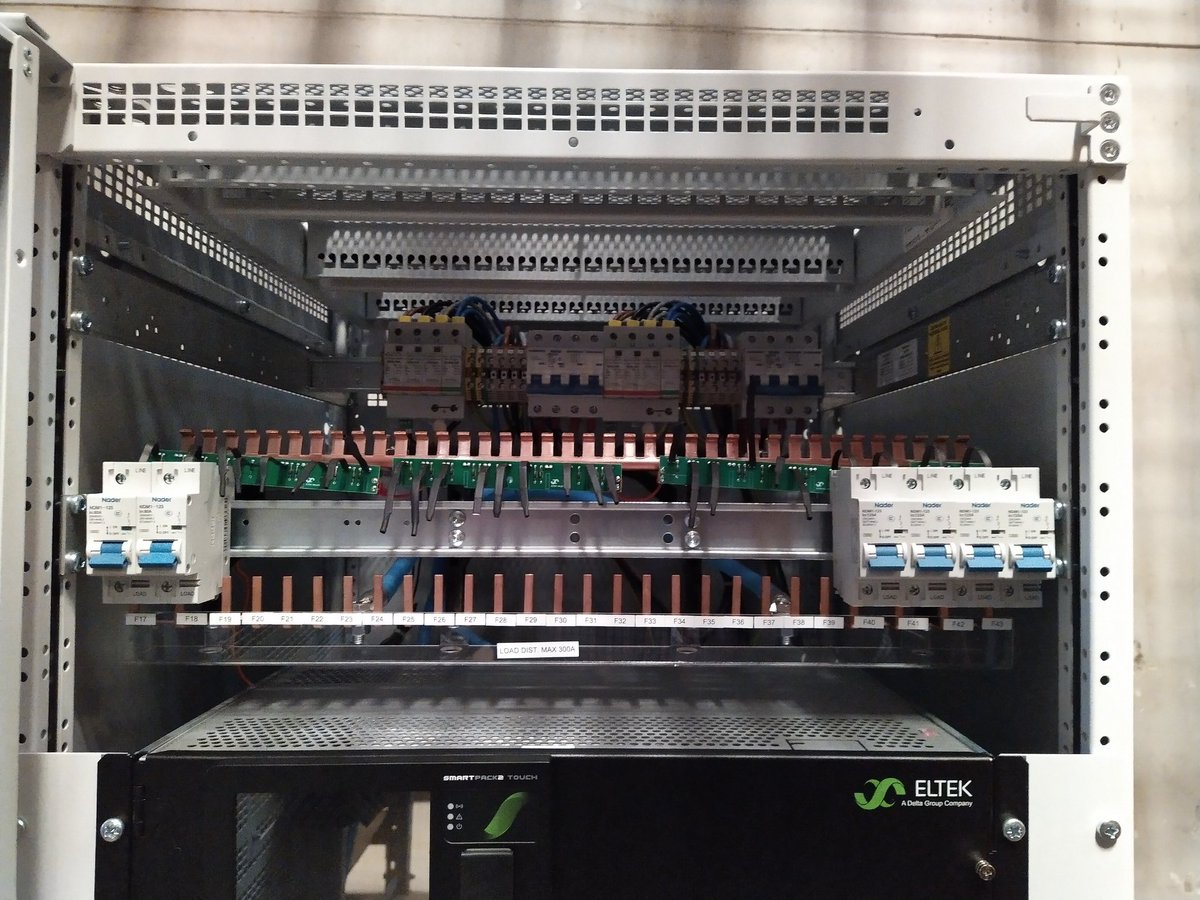

My 4 bulls from Slovakia are here. Sadly with so much going on nothing happens now. It& #39;s a custom integrated hybrid system (Solar, Grid) that& #39;s basically a rectifier (AC to DC) and PV Module Charging system (DC to DC charger) with priority options on both charging and load system

Just received another toy for me to play around with! A slight difference to the 1kVA model; Has both AC In and Output breakers inbuilt). Separately I have a 175A Battery Breaker. Already made recommendations to Magnizon to have the battery breaker inbuilt for ease of monitoring

It also has an SNMP slot for web management via IP address. SNMP card is sold separately for approx. USD305 (abit expensive. Almost half the cost of the 1kW Hybrid system!).

If I have energy to leave the house, I will do the installation tomorrow! https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen"> https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">

If I have energy to leave the house, I will do the installation tomorrow!

For this system (PV Current = 60A, input Voltage range (145VDC) and Max Power (3,500 Watts), I can do around 11Nos 310Wp Solar panels. Should generate approx. 21,000Wh per day for 6Sun-Hours. (equivalent of 21kplc tokens). With a good battery bank, that& #39;s heaven on earth!

Serious Throwback! Lakini hii kazi ya Stima/Solar pia has taken me places! Wueh. This was 3kWp Hybrid system (PV system plus Generators) were doing for Garissa, Daadab, Liboi & Dhobley in Somalia in 2016-2017! Two of the sites still going strong, sadly two were vandalised.

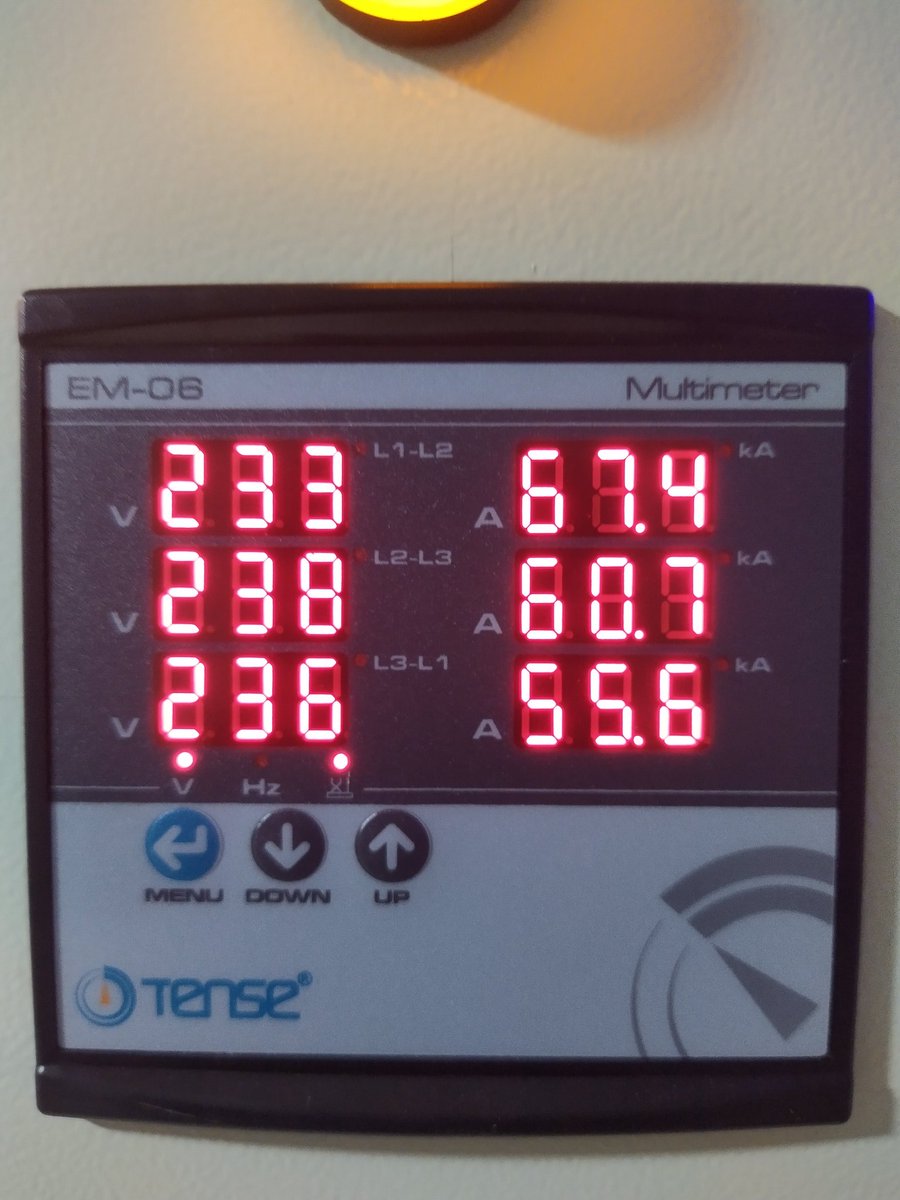

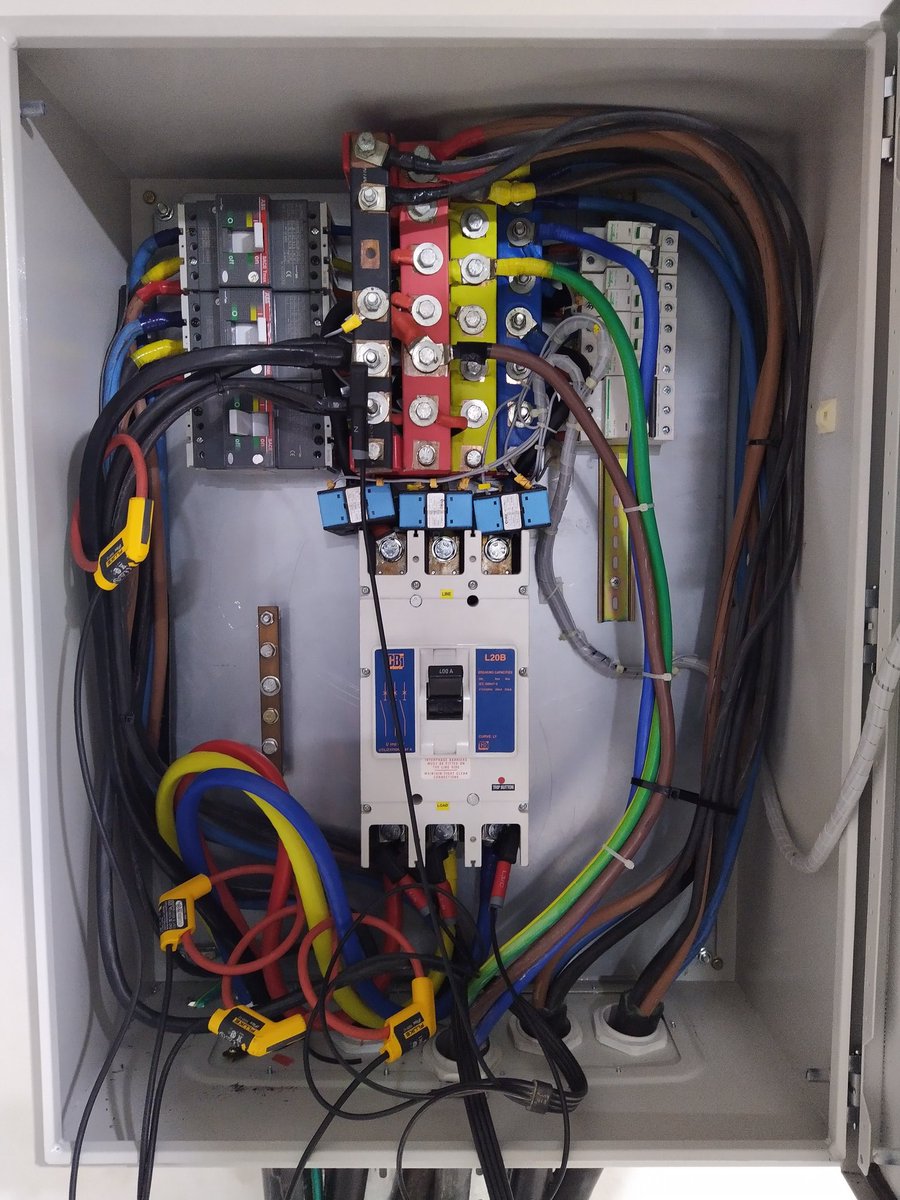

Client& #39;s Audit. 3,840Wp PV system (16Nos 240Wp PV panels) and 38,400Wh battery bank system (16Nos 200aH batteries in 4Nos 48V strings). Inverter size - 6kW/48V system. Peak load as per my clamp is 640 watts, Average load is 272Watts. The system is "hybrid"~ AC charging included

First, there is cabling chaos. Wrong sizing(btwn PV and Charge controller, and btwn Charge controller and batteries), extra long cables & poor cable termination techniques (Hard wiring, not insulated) and wrong battery termination sequence. In effect batteries are under charging

Client& #39;s Power Audit, including recommendations on Safety, Efficiency & PV Hybrid Solution. Clamp set for 5 Days & at Day 2 we can determine the size of his inverter (5kW). He wants Solar PV/Kenya Power supply at 30:70 ratio, that is PV to supply 30% of approx. 4.5kW (1.35kW)

So many times I get "Wamesha size, wewe quote Tu Hiyo List Nimekutumia!" With solar, there is no room for inaccuracies in Surveying and Sizing. The data must be a representation of the actual. I personally go through the survey data, sizing myself and come up with my own BOQ

This is an example of an actual client survey report in Vihiga County. It gives a proper description on how we determine each item of the BOQ & also a brief summary of ROI & CBA.

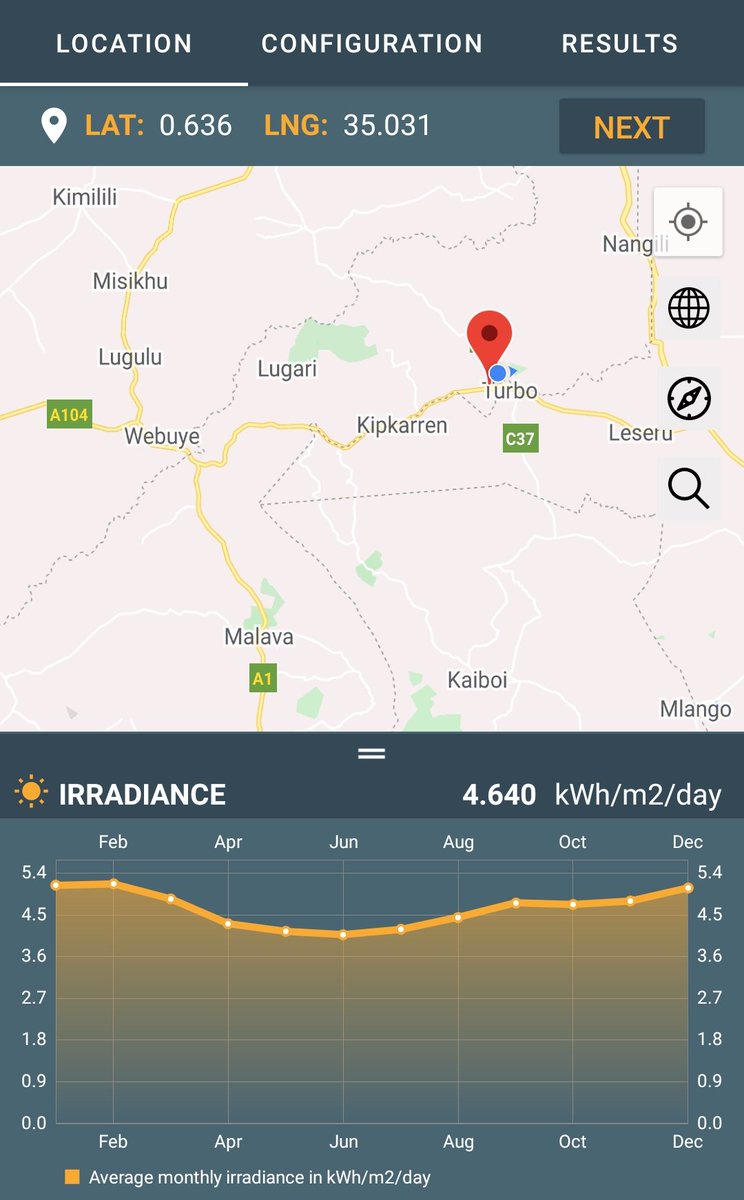

Separately, there is an irradiation map that I use to estimate daily sun hours of different regions

Separately, there is an irradiation map that I use to estimate daily sun hours of different regions

From that Solar Irradiation map, it& #39;s very Clear a Solution for Nairobi might not necessarily be the exact solution for a town closer like Thika for the same Load profile. Therefore survey for each site is very critical

And it& #39;s the reason somewhere up this discussion I said the 55MW Solar Plant built in Garissa County might not be as efficient as a similar plant that would have been Installed In Lokitaung (Turkana County). In this Case temperature plays a critical part

FYI Cost for a Solar Home System (SHS) varies between Ksh. 60-75 per kWH Vs NPV(by my estimates based on my various design Systems). The Variance is due to different batteries, PVs and Inverters currently market but it& #39;s consistent with worldwide rates as of 2020 for SHS.

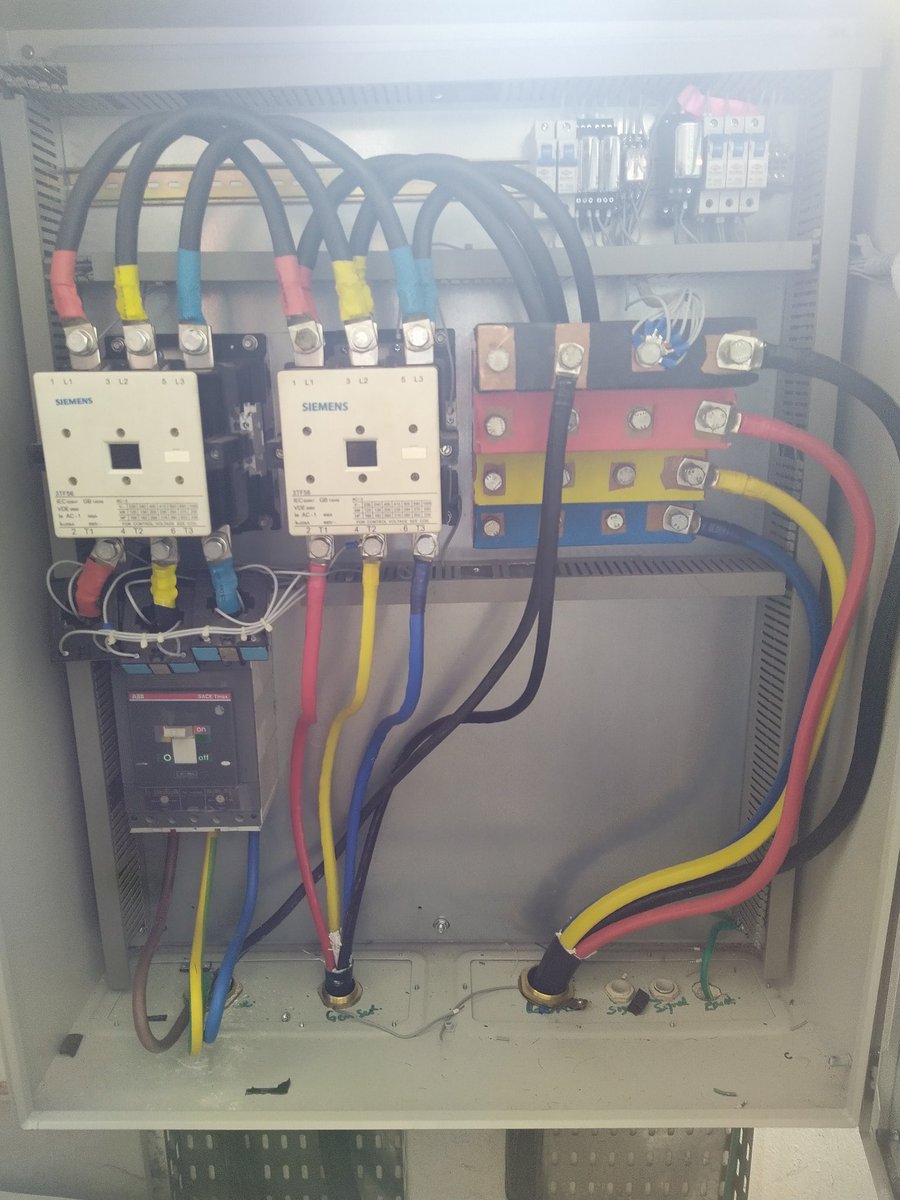

We haven& #39;t been here for sometime. Sooo I will do something small about energy efficiency;How energy efficient equipment assist lower the cost of power. I am currently doing Data Centre Clean up ~ UPS, DB & ATS Upgrades.

Somewhere along this thread we talked about power factor...

Somewhere along this thread we talked about power factor...

Replacing 1 20kVA single phase UPS and 1 15kVA three phase UPS with 2 80kVA three phase UPS. Upgrading Cables btwn Genset and ATS, Replacing Cables btwn ATS and 3phase DB, and Upgrading the ATS from 125A to 400A, and DB from 125A to 400A. Will share photos laters and reason why

Optimization & Improving System Efficiency ~ Recovery of a Legacy 20kVA UPS; Replacement with 8kW (Scalable) Rectifier, 6kVA Non-Charging Inverter and 48V,190aH Battery Bank. Load optimized from 8kW to 1.2kW, Meaning biggest Chunk of Power was being taken up by UPS old batteries

Haven& #39;t DIY& #39;ed for Sometime. Decided to do a survey for a client in Turbo. As part of the Survey, we needed to Calculate NRC & MRC for Elec Vs Solar installation to see the viability (Transformer iko mbali). That advises on the Capex (As I have said, Solar is Capex Intensive)

Captured his Load profile, plus all environmental and physical parameters. So it& #39;s just BOQ na kazi iendelee. Ofcos there was a business case for doing Solar, with a payback period of 4.5years.

On Car batteries ~ Just coZ the indicator "shows green" doesnt mean it& #39;s okay. My neighbor& #39;s been having battery issues~Shows green but can& #39;t understand why cant crank! Tested it and it& #39;s dead. Less than 40 cycles remaining. Most of these cars have been lying idle In yards abroad

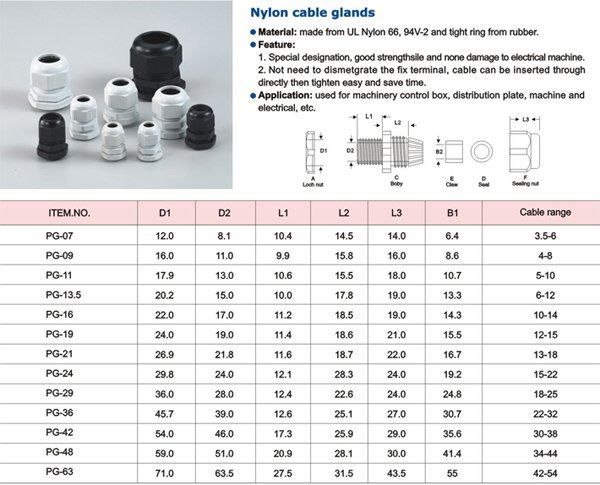

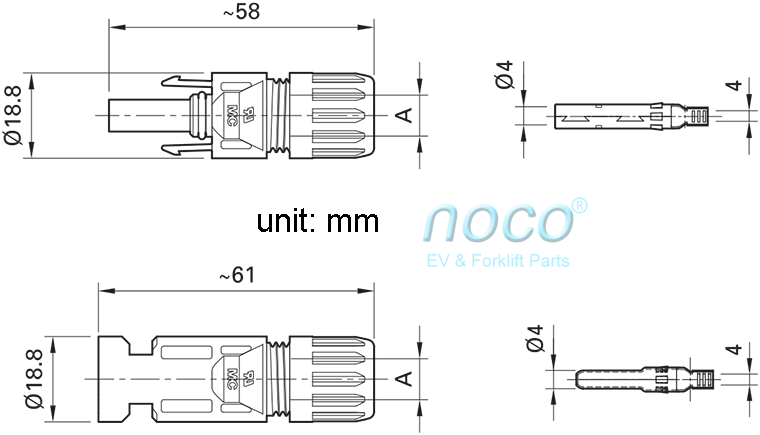

DIY! Have Some 1.2kWp Setup to do, & Instead for going for an expensive Combiner box decided to build one from an unused wireless outdoor kit (Moi Uni Guys remember Butterfly?). Only need the Enclosure which will house my Fuse Blocks, terminal blocks, incomer & SPD

Will add MDF board where I intend to mount the Din Rail, Wall Mount Screws and Cable Glands to Seal the Extra Holes. It will consist of;

1. 4Nos 10A Fuse plus holders

2. N & E Terminal Blocks

3. PV Isolator/Breaker 40A

4. Surge Protection Device

5. MC4 M/F Connectors I/O

1. 4Nos 10A Fuse plus holders

2. N & E Terminal Blocks

3. PV Isolator/Breaker 40A

4. Surge Protection Device

5. MC4 M/F Connectors I/O

Anyway since my rugby plans were disrupted just before @mckennarific atume email (lol), I decided to be a fundi and continue with my DIY. What& #39;s pending are PG Glands to Seal extra homes, and Step Drill Bit to enlarge some of the holes to fit the MC4 connectors. Haziko kakamega

My DIY PV Combiner Box is Up(although some components didn& #39;t get to Siaya in Time ~ Had to Re-engineer most of the things), Connected to the PV and the Hybrid Inverter Charger. Finished setting abit Late so Couldn& #39;t Do a Proper Yield Test. 39VDC & 14.66A as at 3:30pm, which is ok

Was abit Worried about the Distance of the Cable from PV to Inverter (We had to Change location for security reasons), but insignificant Voltage Drop - Used a 22M, 25mmSQ UV Rated Cable. Will ascertain the actual loss at peak production). Additionally to chopping off some tree

Branches next to the PV Setup. One panel completely shaded as at 4pm. Should be okay once that& #39;s done! Total Load current (Max) is at 7A (168W), so at 50% discharge our system should sustain our load for atleast 24 hours with no sunshine.

Read on Twitter

Read on Twitter

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW" title="Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma. https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW" title="Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma. https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW" title="Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma. https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW" title="Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma. https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW" title="Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma. https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW" title="Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma. https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW" title="Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma. https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW" title="Lesson is back, but Looks like the weather will be bad today and tomorrow. Wanted us to do what we failed to do in Bungoma. https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="🤣" title="Lachend auf dem Boden rollen" aria-label="Emoji: Lachend auf dem Boden rollen">. We will try tomorrow. Setting up a Solar PV plant for one of my sites. Same concept as for domestic load. This site& #39;s load profile is approx 2.5kW">

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">" title="It also has an SNMP slot for web management via IP address. SNMP card is sold separately for approx. USD305 (abit expensive. Almost half the cost of the 1kW Hybrid system!).If I have energy to leave the house, I will do the installation tomorrow! https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">" class="img-responsive" style="max-width:100%;"/>

https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">" title="It also has an SNMP slot for web management via IP address. SNMP card is sold separately for approx. USD305 (abit expensive. Almost half the cost of the 1kW Hybrid system!).If I have energy to leave the house, I will do the installation tomorrow! https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">https://abs.twimg.com/emoji/v2/... draggable="false" alt="😂" title="Gesicht mit Freudentränen" aria-label="Emoji: Gesicht mit Freudentränen">" class="img-responsive" style="max-width:100%;"/>